mill liners

Buy Wholesale mill liners Makeup For Larger Eyes And Contrast - Alibaba

Mill Liners (3420 products available) 1 / 6 Mill Liner Factory Custom Cover Lining Plate Jaw Crusher Liner Plate Ball Mill Liner $3.50-$8.00/ kilogram 100.0 kilograms (Min Order) 6 YRS CN Supplier > 5.0(32) | "Fast delivery" Contact Supplier Ad 1 / 6 ASTM A532,AS2027,G-X300 High Cr Cast Iron Coal Mill Liners, EB6019 $2.10-$3.70 / kilogram

Learn More

News - Common Types of Mill Liners

These mill liners are usually used in ball mills, and it has become quite sophisticated with time, improving the quality of its maintenance. High-low double wave ball mill liners. It is an upgraded version of the wave blocks mentioned above. You need to measure the face angles of this mill liner correctly or it will wear out the balls quickly

Learn More

Cutting-edge Mill Liners

Mill liners fill a basic role: to protect your mills from the intense wear and tear that comes from grinding down hard, raw materials.

Learn More

Customizable Mill Liners, Hot Sales in Large Quantities

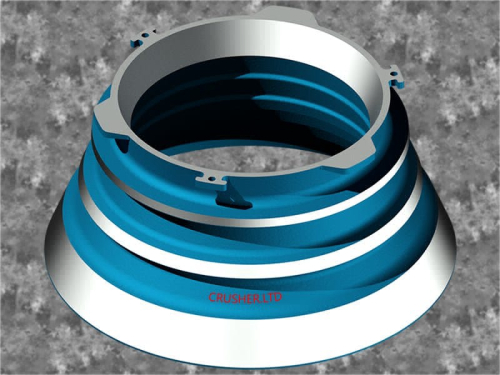

Depending on the mill size and material being ground, a lining system can be manufactured from either rubber or composite, with cast metal alloy inserts moulded into the liners at wear critical locations. In large diameter SAG mills, for example, high energy impacts may require the use of abrasion resistant hardened plate inserts.

Learn More

Steel-casted mill liners for mining - Fundiciones Estanda

Mill liners. Metallic liners for all kind of SAG mills, AG, ball mills and rod mills present in the grinding processes of minerals. Liners profile design

Learn More

Polycorp - Ball Mill Liners

These liners are custom designed for your mills. Mining Ball Mill Liners PolyStl™ Liners PolyStl™ liners are composite of Special Wear Resistant Steel and High Pressure Moulded Rubber which are suitable for AG Mills, SAG Mills, Primary Mills and Ball Mills with ball diameters 3 ½ inches and larger. Learn more PolyBlok™ Liners

Learn More

Mill Liners Filterui ImagesizeLarge

Mill Liners MultotecA broken liner, which is particularly severe for large AG/SAG mills, can arise from media impacting directly on the mill liner Multotec's r Email: [email protected] онлайн общение:

Learn More

mill liner for sale, mill liner of Professional suppliers

Mill Shell Liner End Liner Grate Liner Grind Lining Product Description: Cast grinding ball mill liner, Mill liner plater, Ball Mill wearing plater, wear plate: A. Chrome Alloyed Ball Mill Liner Plates B. Chromium-Molybdenum Alloyed Ball Mill Liner Plates C. High Manganese Steel Ball Mill Liner Plates Products Apllication: Casting grinding ball

Learn More

Game changing mill liners - International Mining

Game changing mill liners. An interview with Mathias Kuhrke - Global Product Manager – Mill Lining Systems and Hayden McLean, Regional Product Manager

Learn More

Mill Liners | Multotec

A broken liner, which is particularly severe for large AG/SAG mills, can arise from media impacting directly on the mill liner. Multotec’s rubber mill linings are designed by combining the results of

Learn More

Vulco® Mill Lining Systems | Weir Group

Vulco® mill linings are custom-designed for each grinding application with consideration given to available mill power, trunnion bearing loads, mill weight restrictions, grinding media charge volume and service life. Designed using most up-to-date technologies and design tools to ensure an optimum system design and accurate liner fit.

Learn More

Mill Liner plate - mill linings Latest Price, Manufacturers

These liners are used in Ball mills where low contamination is required. Contamination with Alumina Ceramic lined ball mill is low due to their extremely low

Learn More

Common Types of Mill Liners - Qiming Machinery

These mill liners are usually used in ball mills, and it has become quite sophisticated with time, improving the quality of its maintenance. High-low double wave ball mill liners. It is an upgraded version of the wave blocks mentioned above. You need to measure the face angles of this mill liner correctly or it will wear out the balls quickly

Learn More

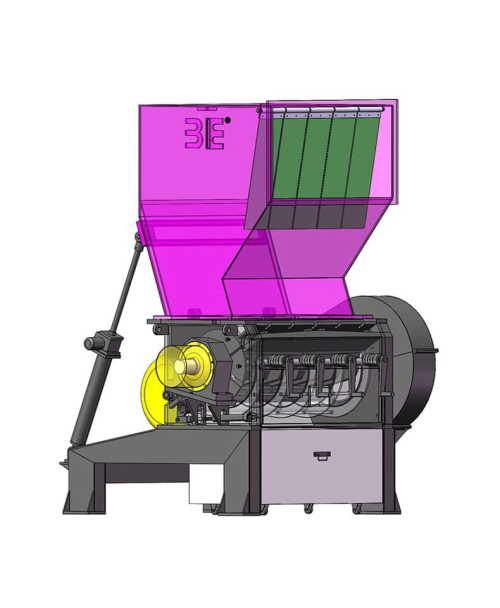

Mill and Crusher Liners - Bradken

Bradken is a leading engineering grinding mill solutions provider, supported by design and manufacturer of high-quality mill liner components to suit AG/SAG, Ball and Rod Mills. By utilising the latest research and technologies, we provide customers with advanced Mill Liner Solutions and products that improve mill performance, safety and

Learn More

Mill Liners Manufacturers, Suppliers, Wholesalers and Exporters

Supply Type: oem service. Processing Time: 30-50Days. Currency: USD. Min Order: 1. Chaoyang Runxing Heavy Manufacturing Co.,Ltd. Business Type: Manufacturer. Key Products: girth gear

Learn More

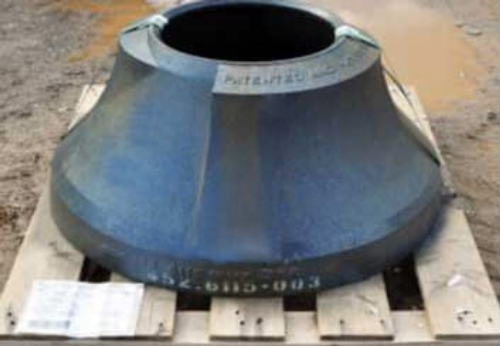

Grinding Media, SAG Mill Liner, White Iron Mill Liner - H&G

Sep-18-2021. H&G deliver 2 sets of high manganese steel mill liner for SAG 5.5*1.8 H&G deliver 2 set

Learn More

Poly-Met mill liners - Mill linings from rubber and steel - Outotec

Skega Poly-Met™ mill linings combine the most desirable properties of rubber and steel. The linings are carefully designed to maximize the availability of your grinding mill and keep your costs to a minimum. Benefits Increased uptime Long wear life and increased availability Ease of maintenance Low lining weight Lower maintenance costs

Learn More

Teknikum® Mill Liners

Most innovative Mill Lining components on the market! With over 30 years of expertise, Teknikum develops proven customer-specific Mill Lining solutions.

Learn More

Mill Linings for Sale, Types of Ball Mill Liners. - ball mills supplier

The mill liner is installed inside the ball mill barrel to protect the inner wall of the barrel from the impact of materials and grinding media (steel balls, steel sylpebs, steel rods, etc.) to avoid

Learn More

Mill Liners Price

you can buy quality mill liners at factory price / low price in China. Ball Mill Liner Price Rubber Liner Price Steel Liner Price Wear Liner Price

Learn More

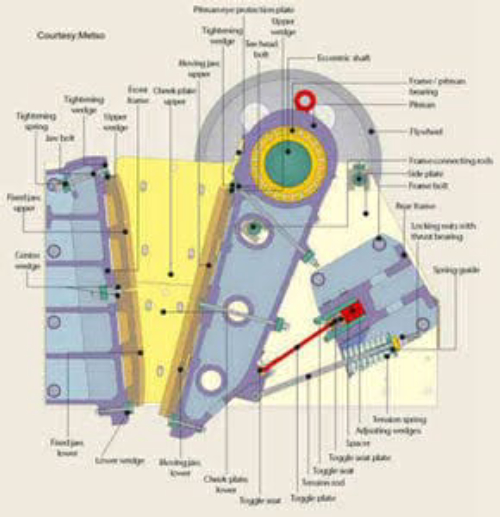

PDF] The selection and design of mill liners - Semantic Scholar

Dramatic shortcomings of mill liner designs, especially of large SAG mills, such as rapid failure and even mill shell damage arising from impacting of the

Learn More