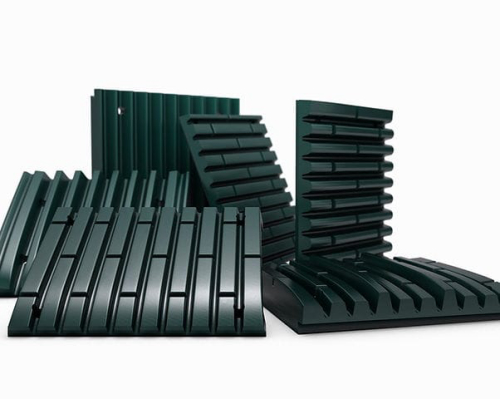

poly met mill liners

Evaluation of Abrasive Wear Measurement Devices of Mill

Mill Liners, Wear measurement, Mining, Mills, Measurement devices, Evaluation, Quality index. 1. INTRODUCTION. Mills used in the mining industry and ore.

Learn More

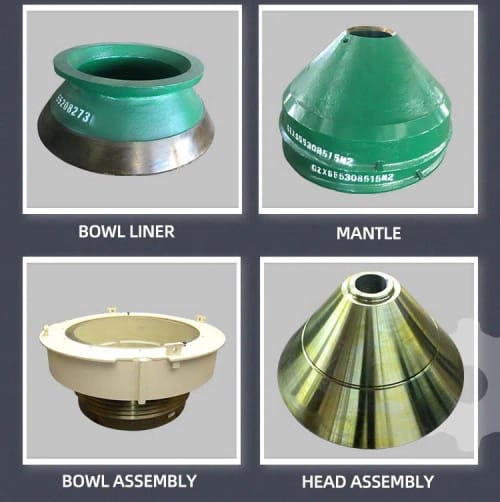

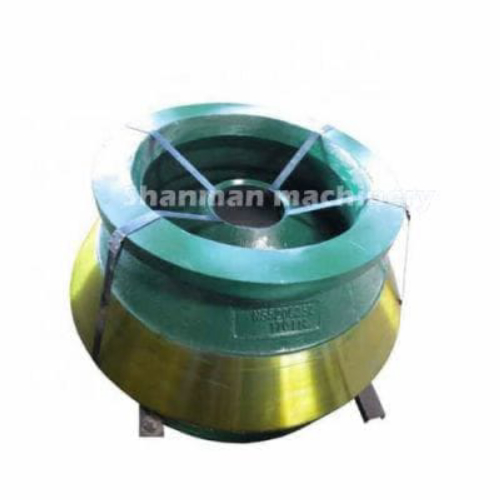

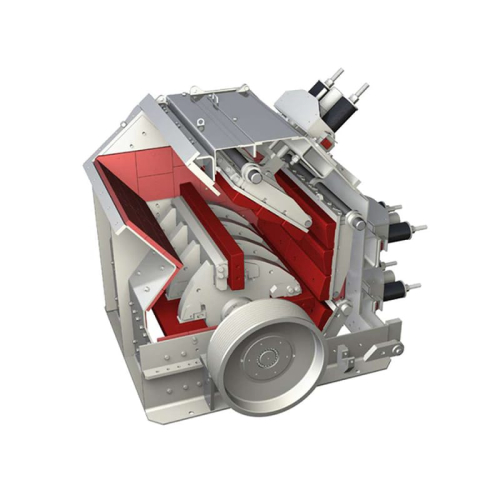

crusher | poly met mill liners

EXCEL™ spare parts and liners for ® MP™ cone crushers. Our cone crusher spare parts for Compression Crushers are improved over OEM standards, allowing for longer wear life and better performance. (PDF) Crushing and Screening Handbook.

Learn More

Polymet-Rubber mill liner-Megaliners - Matec solutions

Customized Mill liner Parts for ball mill, SAG. Home Home. About Us About Us. Overview; Manufacture; QHSE; Products Products. Crusher Parts; Slurry Pump; Hydrocyclone; Screening

Learn More

Grinding Mill Poly-Met Parts - Matec solutions

Poly-Met Mill Liners Poly-Met liner combines the most desirable properties of rubber and steel to maximum advantage. This combination allows the use of more wear resistant alloys of iron and steel than can be used in a conventional metallic lining, as the rubber substantially dampens the impact forces and also results in a lower lining weight.

Learn More

Poly-Met mill liners

Poly-Met mill liners . Poly-Met polymetallic linings are most in demand on the market due to the optimal combination of rubber and steel properties. This combination allows the use of more

Learn More

s Megaliner Poly-Met shell liner | Aggregates Business

s new Megaliner Poly-Met shell liner is said to keep downtime in large mills to a minimum, utilising an innovative design that offers speedy

Learn More

Vulco® Mill Lining Systems - The Weir Group

With advanced materials, Vulco® wear-resistant rubber and metal cap mill liners are versatile, economical and efficient products for grinding circuits.

Learn More

Poly-Met Liners for Ball Mills - China Poly-Met Liners for Ball

Poly-Met Liners for Ball Mills, Find Details about Poly-Met Liners for Ball Mills, Poly-Met Liners from Poly-Met Liners for Ball Mills - Anhui Sinow Rubber Products Co., Ltd. Search Mill Part. Power Source: Electricity. Object: Mill. Application: Mineral Separation. Material: Rubber.

Learn More

Z289 LINER BASE LINER "34" RH | poly met mill liners

Z289 LINER BASE LINER "34" RH XL6500U. RE RD RH. AM. IRF PCB ASSY. Run the AM lead wire through the notch of the front holder L. Fig. 5-4 - 34 - Lead wire routing after the optical unit and IRR PCB ASSY are attached IRR PCB ASSY optical unit Run the SL lead wire through the hook of the optical unit. Clamp the brown and red lead wires with the band.

Learn More

Poly-Met mill liners - Sever Minerals

Poly-Met mill liners. Poly-Met polymetallic linings are most in demand on the market due to the optimal combination of rubber and steel properties.

Learn More

Rubber mill linings - REMA TIP TOP

Poly-met mill linings combine rubber and steel, taking the most desirable properties from both and creating a long lasting and high performing lining.

Learn More

High Density Polyethylene 40 mil| HDPE Liner/ Geomembrane

GPS HD 40 mil is a smooth, high quality, high density polyethylene (HDPE) geomembrane produced from specially formulated, polyethylene resin. This polyethylene resin is designed specifically for flexible geomembrane applications. It contains approximately 97.5% polyethylene, 2.5% carbon black and trace amounts of antioxidants and heat

Learn More

Poly-Met Mill Liners for Autogenous and Semiautogenous Grinding Mills

Poly-Met Mill Liners for Autogenous and Semiautogenous Grinding Mills Previous Next Over 25 years ago, SKEGA pioneered the use of rubber linings in grinding mills and rubber is today widely accepted and almost standard material chosen for Regrind and Secondary Mills.

Learn More

China Poly-Met Liners for Ball Mills

The Poly-Met liner includes Poly-Met shell plates and lifter bars; feed and discharge head end plates, lifter bars, pulp lifters and grate plates, The Poly-Met liner is made of highly wear-resistant rubber and alloyed steel such as the highly wear Sweden HARDOX steel plate under high temperature and pressure. Send your message to this supplier

Learn More

PDF) Ball mill Polymet liner evaluation at PT Newmont Nusa Tenggara

These new liners were installed in two of the ball mills (ball mills 1 and 2) and operated in parallel with ball mills 3 and 4 with steel liners. The objective of the trial was to compare the plant

Learn More

Tips to improve grinding profitability with mill liners

Our Poly-Met liner concept retains an efficient profile, similarly to metallic mill linings, as different types of wear-resistant inserts

Learn More

Mill Liner Manufacturers - Grinding & Classification Circuits

Am looking for the most or best Wear Resistant Mill Liners and manufacturers. Please could you advise what your recommendations for the best possible liners to use in an Iron Ore application and please share what %Mn was used including the % Cr if used and also any other Alloying and special treatments that was used including the % for each.

Learn More

Poly-Met Mill Liners for Autogenous and Semi Autogenous

Poly-Met Mill Liners for Autogenous and Semi Autogenous Grin Effects of Operating Parameters on Grinding Steel Consumptio Value Based Grinding Circuit Control Ore characteristics that Affect Breakage and Mineral Liberat Are you at Risk? The Role of Environmental Auditing in the L Environmental and Reclamation Measures at Equity Silver Mine

Learn More

Mill linings, mill trommels and trunnion linings

Poly-Met mill linings Mill linings from are high quality products with long wear life. The development of the Poly-Met concept led to the first patent in 1987. The Poly-Met concept combines the most desirable properties of rubber and steel to maximum advantage.

Learn More

Poly-Met mill liners - Mill linings from rubber and steel

Skega Poly-Met™ mill liners. Suitable for SAG mills, AG mills, ball mills, FGD mills, rod mills, scrubbers and washing drums. Features.

Learn More

Poly-Met mill linings | Outotec

Skega Poly-Met™ mill linings from Outotec are carefully designed to maximize the availability of your mill and keep your costs to a minimum.

Learn More