rubber mill liners

Rubber Mill Liners | AG SAG Ball Mill Liners | GTEK MINING

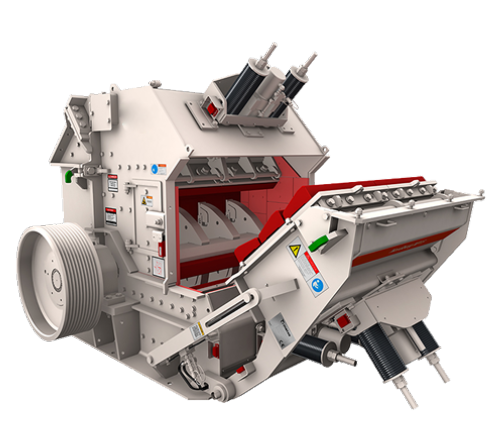

The mill is the heart of mineral processing plant. Rubber mill linings have been used successfully in secondary and regrind milling applications and are specified today for these applications.. However with the support of improved materials and computer aided design programs, rubber mill liners are being used more and more in primary grinding applications as well.

Learn More

Grinding Mill Liners - 911 Metallurgist

Weight: Rubber weighs about 15% of an equivalent volume of steel. This means that a rubber liner system reduces the load on the mill structure

Learn More

Mill Liners « C.C.Components - Complete Conveyor Components

Our Mill Liners offer optimal grinding solutions to major mineral processing plants throughout Australia. Lifters are made of tough abrasion resistant rubber which is able to withstand the relentless pounding of the mill action.

Learn More

Rubber Mill Liners - Alibaba

rubber mill liners can instantly make a person's eyes look bigger and more aesthetically pleasing. Sell wholesale eyeliner to your customers.

Learn More

Rubber Ball Mill Liner - Strudex Mining

Rubber Ball Mill Liner Linings. Rubber linings are lightweight and easy to handle. Rubber mill linings show more wear resistance and require less maintenance. Rubber mill linings absorb impacts on the shell and reduce noise levels. Rubber mill linings have PREDICTABLE WEAR RATIOS, and thus facilitate inventory planning.

Learn More

Mill liners - Outotec

We pioneered the use of rubber linings and invented Poly-Met, Megaliner and Orebed mill linings. New products are constantly being developed to enhance our customers’ ever more advancing

Learn More

Mill Lining Systems | FluidHandling - Trelleborg

Trelleborg has a wide range of rubber lifter bars and plates for ball mills, rod mills and drum scrubbers. Our MILLTOUGH® EXTREME composite lifter bar is

Learn More

Vulco® Mill Lining Systems - The Weir Group

With advanced materials, Vulco® wear-resistant rubber and metal cap mill liners are versatile, economical and efficient products for grinding circuits.

Learn More

Rubber Mill Liners | FRASERS

24 Rubber Seals; 23 Tank Liners; 22 Mills; 22 Rubber Extrusions; 21 Rubber Sheeting; 21 Rubber Rings; 21 Metal Milling; 20 Rubber Extruded Gaskets; 20 Extruded Rubber; 19 Silicone Rubber Products; 18 Tapping & Milling Transfer Drilling Machines; 18 Spray-on liners; 18 Pulp & Paper Mill Equipment;

Learn More

Rubber Mill Liners Market Report | Global Forecast To 2028

The global rubber mill liners market is expected to grow at a CAGR of 4.5% during the forecast period, to reach USD 1.2 billion by 2030. The growth of this market is driven by the increasing demand for rubber mill liners in various industries such as mining, cement industry, and thermal power plants. The mining industry is one of the major end

Learn More

Rubber mill lining

Rubber mill lining. Ball mills are used for fine grinding of materials. This application is present in mining, where the ore is milled, in the ceramic

Learn More

Polycorp - Rubber Liners

Rubber Mill Liners are extensively used in FGD mills at Power Plants all over the world. Polycorp has supplied complete rubber linings in some of the largest ball mills in South America at 26

Learn More

Ball Mill / SAG Mill Steel Shell Liners - Unicast Inc

Longer Wear Life: Unicast Rubber Liners are pressure molded to ensure highest density and engineered for maximum abrasion resistance. · Reduced Weight Lowers

Learn More

Compare the Benefits of Steel VS Rubber/Poly-Met Mill Liners

24/07/ · Let’s compare! Rubber Liners are better for abrasion grinding ie: cascade action but not for cataract mills. The graph below shows the increased operating cost of rubber and steel liners as the grinding ball size increases. Larger mill, larger ball increases the cost benefit of using steel only mill liners. Looking at this chart, any time

Learn More

Ball Mill Liners Selection and Design | Ball Mill Rubber Liner

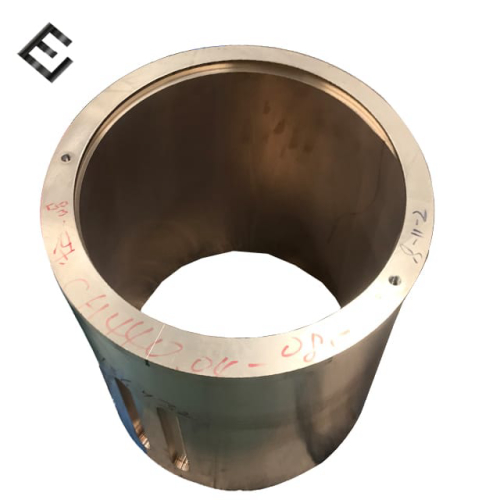

19/05/ · The mainstream ball mill liners materials currently used in the market are alloy steel and rubber. Alloy steel mill liner is wear-resistant and impact-resistant. Alloy steel has good

Learn More

Polycorp - AG/SAG Mill Liners

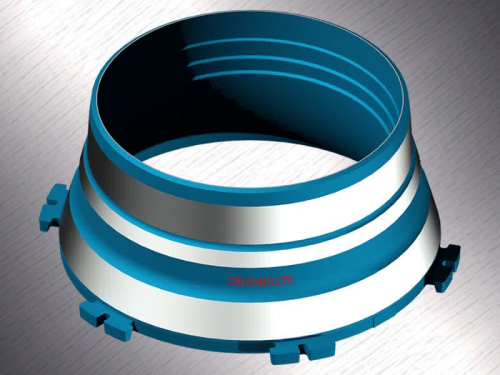

AG/SAG Mill Liners. We have supplied rubber pulp lifters for SAG mills up to 40 ft in diameter. We are pioneers in the design of both radial and curved pulp lifters, also design and manufacture Rubber / PolyStl™ grates and discharge systems. Mining.

Learn More

Key considerations when selecting a mill lining system - The Weir Group

Rubber and composite mill liners are increasing in popularity, with several advantages when compared to metal mill liners: Ease and speed of manufacture, with shorter lead times Customisable, with ability to optimise abrasion and wear resistance Outlast metal linings when designed and manufactured correctly

Learn More

Rubber Mill Liners - Multotec

Why use Multotec Rubber Mill Liners: Greater wear resistance extends the lifespan of your equipment. Quick to install and replace, reducing downtime. Their low weight results in less

Learn More

Rubber and Composite Mill Linings - MPS Mining Products and Service

Mining Products and Service (MPS) has over 20 years experience in Rubber and Composite Mill Linings. MPS personnel have extensive experience Mark : +61 408 222 546 / Rolf : +61 400 904 334 / Eddie : +61 408 095 985

Learn More

Elastic polyurethane Mill liners - Eurogomma

Comparative test between premium quality Rubber liners and EUROGOMMA elastic polyurethane liners. Polyurethane case study 01. Polyurethane case study 02.

Learn More

Rubber Mill Liners - Wear Parts For Industry | Qiming Casting

Polyurethane rubber mill liners’s working life 5-10 times than normal metal mill liners in some work conditions; Polyurethane rubber mill liners weight less than metal mill liners, which easy to carry; Because the no-load load is reduced, the power saving effect is obvious. Under the normal load condition, the new polyurethane liner can save

Learn More