crusher liners

Jaw Crusher Plates | Chrome White Iron

Nanhai Heavy Machinery Inc. offers high-quality products for mining like cone crusher liners, jaw crusher plates, chrome white iron protective covers, etc.

Learn More

Crusher Liners, Shredder Parts, Mill Liners Foundry- Hunan JY Casting

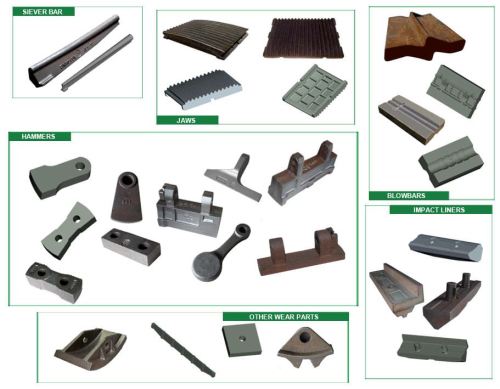

What We Offer Hunan JY Casting manufactures crusher wear parts (cone crusher liners, crusher jaw plates, crusher blow bars), shredder wear parts (shredder hammer, grates, caps, anvils), mill liners (lifting plates, shell liners, end liners), and apron feeder pans for the most popular brands. Custom or OEM Wear Parts

Learn More

Crusher Liners | Cone Crusher Liners | Crushing Wear Parts

Crusher Liners CSP is a leading supplier of cast, forged, and fabricated wear solutions to OEM and aftermarket crusher operators. We have over 30 years' experience supplying crushing wear parts to global mining and mineral processing, oil sands, steel, cement, power and aggregate customers.

Learn More

Selecting crushing chambers for cone crusher

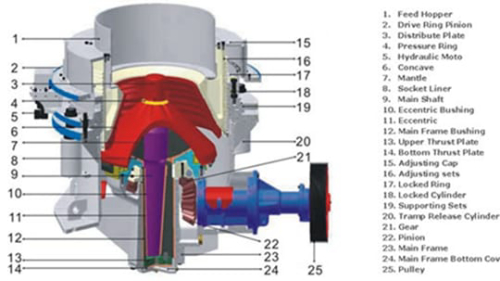

Illustrative figure of HP cone crusher liners. To ensure the suitability of the liner profile for its application, it is important that

Learn More

Shell Liners | Crusher and Mill Liners | CITIC HIC

CITIC HIC has a wear liner production base with annual capacity of 30,000 tons of wear-resistant castings. At the production base, we can produce a variety of wear liners for crushers, grinding mills and vertical stirred mills. Through from casting process design, mold making, smelting & casting, heat treatment, quality inspection, to packaging

Learn More

Kenco Longer Wearlife Parts | HSI Apron Liners

Tungsten carbide impregnated AR steel apron liners out wear manganese in certain HSI crusher applications; Elimination of premature apron liner wear greatly

Learn More

Cone Crusher Liners For Popular Brands With Various Material

Cone crusher concave, which sits in the upper frame of the crusher to protect it from wear. It is the outer sacrificial wear liner that sits inside the upper frame. Common Aliases: Cone crusher

Learn More

Get Crusher Liners & Part Coating In Australia - Australac

ACE's comprehensive range of products vary from standard and customised cone crusher liners such as concaves, mantles, torch rings, feed cones and bolts,

Learn More

Prolonging Cone Crusher Liner Life | Agg-Net

Results. The 18% manganese liners used prior to the trials lasted for a maximum of 12 weeks (16,800 tonnes through crusher). The first trial liners using hardfacing lasted 38 weeks (53,200 tonnes through crusher), providing 216% extra life. As this proved such a success, it was decided (correctly) that a lower-cost manganese could be used.

Learn More

Manganese - ELRUS Crusher Parts

elrus-jaw-liner-manganese Jaw Manganese. ELRUS jaw crusher manganese is manufactured to factory specifications and dimensions. All jaw plates are available

Learn More

Cone Crusher Liners Selection - Wear Parts For Industry | Qiming Casting

2.Crusher Liner’s Material. Cone crusher wear parts, concave and mantle, are casting by manganese steel. Mangalloy, also called manganese steel or Hadfield steel, is a steel alloy containing an average of around 13% manganese. Mangalloy is known for its high impact strength and resistance to abrasion once in its work-hardened state.

Learn More

Tips For Buying Crusher Wear Liners - Qiming Casting

New wear liners supplied for your crusher are usually supplied neatly painted and packed for good presentation. An initial visual inspection is usually all that is possible and provided there are no surface imperfections present the liner is stored for later use. There may be an incentive to dispose of worn crusher liners and clean up the yard.

Learn More

Manganese Parts - Australian Crushing and Mining

Our Manganese & Chrome liners are of the highest quality and have been known and proven to consistently out last and out Finlay Cone Crusher Liner.

Learn More

Parts 48′ Gyradisc upper liner | maintenance of vertical roller

Our high quality crusher parts are made for the HP Crusher 300 and 400 series, Gyradisc Crushers 36 48 54 66, and 2 3 4 4.25 5.5 7 Cone Crushers. Symons. For more than 100 years, the ® brand of forming systems has stood as the preferred system for concrete forming around the globe.

Learn More

How to Find the Right Cone Crusher Liners Manufacturer?

There are three basic types of liners for cone crushers. A standard size has a standard diameter. The "A" dimension is the width of the cone liner. It is a standard measurement for all cone liners. A larger or smaller "A" dimension increases the life of the liner and increases the capacity of the machine.

Learn More

Crusher Aggregate Equipment For Sale in HILLSBORO, OREGON - 28 Listings

Browse a wide selection of new and used Crusher Aggregate Equipment for sale near you at MachineryTrader.com. Find Crusher Aggregate Equipment from CEDARAPIDS, KPI-JCI, and , and more, for sale in HILLSBORO, OREGON

Learn More

Gyratory Crusher Liners

Increase your operation's efficiency with our expert knowledge and high-quality equipment. We are the OEM manufacturer of Gyratory Crusher Liners.

Learn More

Cone Crusher Wear Parts - Columbia Steel Casting Co., Inc

For better production and longer wear life, choose Columbia cone crusher liners. · Standard, heavy-duty, and custom wear parts for all popular cone crushers.

Learn More

Cone Crusher Liners - EB Castworld % Cone Crusher Liners

EB uses Mn13, Mn13Cr2, Mn17Cr2, Mn18, Mn18Cr2 to produce Cone Crusher Liners according to the customer’s working environment to effectively prevent the wear during the crushing process and greatly extend its service life. Our Experience: 13 Year Experience in Heat-resistant Steel Field. 18 Year Expertise in Wear-resistant Material Field.

Learn More

Crusher wear parts - Outotec

Crusher wear solutions that match and scale with your needs Expertise built in Insights with competitive advantage OEM quality Applying the strictest standards and tolerances for guaranteed safety and reliability. Availability With 150 distribution centers world-wide, we supply wear parts where and when you need them.

Learn More

Jaw Crusher Liners - Makuri Group

A lack of attention to proper jaw design by OEMs results in poor product shape and high steel usage on jaw crushers, although this is easily resolved with the correct design. In some cases, we have seen jaw liners requiring replacement after only removing 5-10% of their initial mass, resulting in a large amount of wastage and excessive liner cost.

Learn More