cone crusher liners

Hillsboro, OR - Crushers For Sale - Equipment Trader

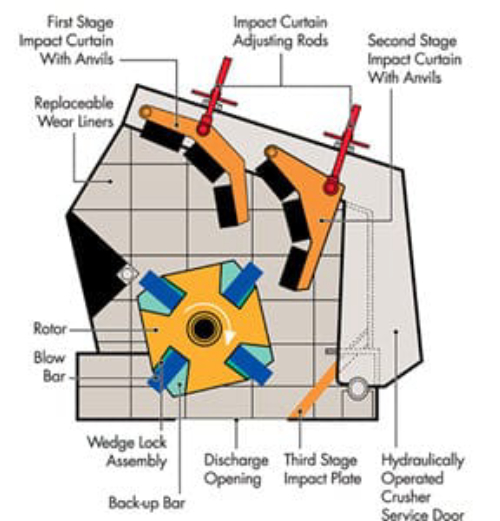

The three main types of crushers are the cone crusher, the jaw crusher, and the impact crusher. Make sure you understand all of the differences between these kinds before choosing one for your project. Regardless of which type of machine you choose, you should be prepared for some very powerful crushing power. Make sure that anyone who is set

Learn More

Cone Crusher Liners | Crusher Mills, Cone Crusher, Jaw Crushers

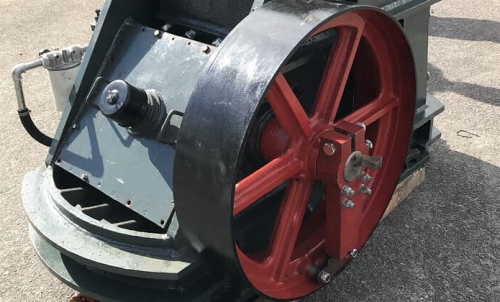

Cone Crusher - CEC SC300 Nixon-Egli Equipment Company. CEC SC-300 Cone Crusher Ultimate speed cone Dual eccentric stroke Revolutionary manganese locking system lets you change the liner in two hours 50° head angle Very .

Learn More

crusher parts loaded on truck, cone liner jaw plate ready for delivery

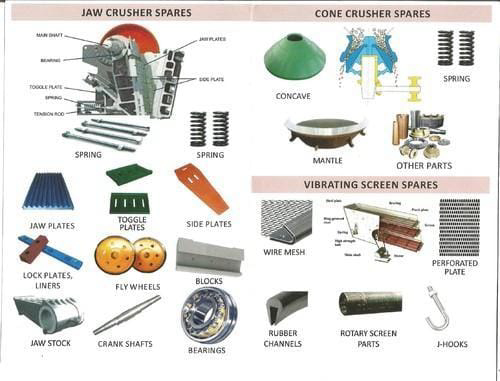

crushtechs specialized in all kinds of crusher and crusher parts.cone liners, jaw liners, cone mantle liner, concave liner, jaw plate, impact crusher parts,

Learn More

Replacing the liner of a HP cone crusher - Outotec

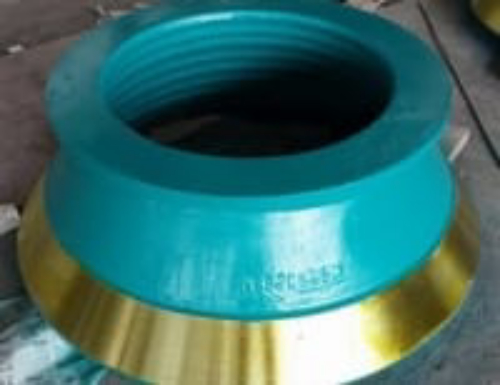

6/9 · The HP cone crusher is a very important piece of equipment in a crushing plant. It can operate as a secondary, tertiary or quaternary crusher, depending on the crushing process. Since the crushing process is typically very abrasive, crushers are equipped with wear linings that must be replaced periodically to ensure the integrity of the equipment and good performance.

Learn More

How to Select and When to Change Cone Crusher Liners

Cone crusher liners reduce the volume of the crushing cavity and feed opening of the cone crusher. If the liners wear out, a 10% loss in production is enough to justify changing them. If not, failure to replace the liners will not only cause a loss in production, but can also damage internal crusher components.

Learn More

Cone Crusher Liners: What To Choose And When To Change

Closed-side feed openings are passing 90-100% There are those who examine 80% of the open side too and choose the lower one of two. 40-60% passing the midpoint. Closed-side Setting Closed-side Setting: 0-10%. Matching the entire feed gradation and not just the feed size is essential so you can make use of your chamber to the maximum.

Learn More

Cone Crusher Liners: How to Select and When to Change

6/23 · 90-100% passing the closed-side feed opening. Some people look at 80% of the open side as well and select the smaller of the two. 40-60% passing the midpoint. 0-10% passing the

Learn More

Crusher Liners | Cone Crusher Liners | Crushing Wear

932 rows · Crusher Liners. CSP is a leading supplier of cast, forged, and fabricated wear solutions to OEM and aftermarket crusher operators. We have over 30 years’ experience

Learn More

Crusher Liners | Cone Crusher Liners | Crushing Wear Parts

Crusher Liners CSP is a leading supplier of cast, forged, and fabricated wear solutions to OEM and aftermarket crusher operators. We have over 30 years' experience supplying crushing wear parts to global mining and mineral processing, oil sands, steel, cement, power and aggregate customers.

Learn More

How To Select Cone Crusher Liners and When To Change Them

12/27 · The Cone Crusher liner should have a well-graded feed flowing into the crushing chamber. This generally consists of: 90 to 100 percent passing the closed-side feed opening.

Learn More

CH540 Cone Crusher Liners - Hunan JY Casting

We are the best CH540 cone crusher liners manufacturer in China. We guarantee that this part was expertly crafted in consideration of original factory tolerances and material specifications. Please quote this part number to our parts team if you would like more information about this genuine alternative replacement part over the phone.

Learn More

cone crusher liner selection - Wear Parts For Industry - Qiming Casting

Cone crusher liner selection, which is very important selection for user. Cone crusher liners need periodic replacement to protect cone crusher and keep the output, so the better selection, the less cost and more profit.In this post, we will discuss from material selection,cavity selection and foundry selection. 1.Material selection:

Learn More

Cone Crusher Liners - China Factory, Suppliers, Manufacturers

Cone Crusher Liners Which has a positive and progressive attitude to customer's desire, our corporation constantly improves our merchandise quality to satisfy the desires of consumers and further focuses on safety, reliability, environmental demands, and innovation of Cone Crusher Liners, 3055 Jaw Plate , Ch890 Cone Crusher Parts , Hammer Mill Stone Crusher , Rc Mining

Learn More

Change Cone Crusher Liners - MGS Casting

1. On the initial set of new linings, put a mark on the change cap chauffeur ring where the pinion tooth reaches a chauffeur ring tooth when the target crusher setting has actually been

Learn More

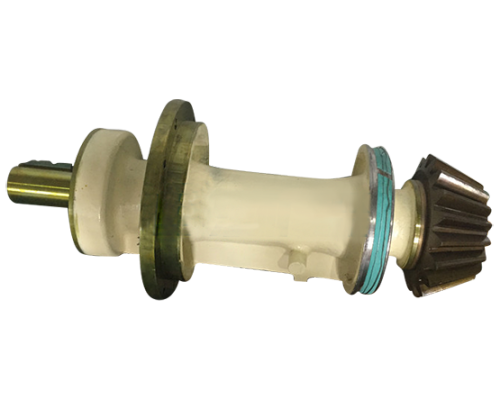

con crusher liner | crushers upper head bushing manual new

The cone crusher liners supplied by us are compatible with cone crushers of , , ,Cedarapds,Kue-Ken and many other well-know makes. All the item names, machine models, part numbers for the cone crusher liners are used . for reference purposes only. Please contact our sales for further confirmation.

Learn More

Cone Crusher Liners | Manufacturing and service of

We understand that to keep your equipment and process running smoothly, it may require an approach that is more in-depth than just choosing a different material grade or Cone Crusher

Learn More

Cone Crusher Liners: What To Choose And When To Change - KeepandShare

Cone Crushers are equipped with crushing chambers. It is the space between the concaves and mantle, which is the moving piece of steel. Concaves and mantles are protected from daily wear by replaceable manganese liners. Selecting a Cone Crusher liner There are numerous liners for both fine and coarse feeds.

Learn More

Crusher Liners | World-Leading Crusher Liners | CMS Cepcor

Cavity and liner selection CMS Cepcor® stock a wide range of cavity liner options for cone crushers along with many jaw plate tooth profile options for jaw crushers and various metallurgies for impact crushers. Quality assured to Lloyds Register ISO9001:

Learn More

Selecting crushing chambers for cone crusher - Outotec

4/7 · This is discussed in more detail in the 12 tips to maximize cone crusher productivity blog post. Summarizing, larger setting → product size increases, capacity increases, power draw decreases. Example: The HP crusher chamber selection table shows the minimum opening settings. However, the presented settings are provided as a guide only.

Learn More

Prolonging Cone Crusher Liners Working Life - Precision Casting

2022/1/18 · Some cone crushers do not use backing but instead have precision-cast and machined liners. Work to reduce we these has been carried out but is not discussed in

Learn More

How To Select Cone Crusher Liners and When To Change Them

12/27 · The Cone Crusher liner should have a well-graded feed flowing into the crushing chamber. This generally consists of: 90 to 100 percent passing the closed-side feed opening. 40 to 60 percent going through the midpoint. 0 to 10 percent leaving the closed-side setting. Match the entire feed gradation and not only the feed shape.

Learn More