rubber ball mill liners

Simple Ore Extraction: Choose A Wholesale rubber ball mill liner

Find the right mine mill from Alibaba. Explore our mining equipment to find the ideal wholesale rubber ball mill liner model and mills for any mining

Learn More

Key considerations when selecting a mill lining system

Rubber compounds have been developed to protect mill shells from wear, while new cast alloys and wear resistant plates can be bonded into rubber

Learn More

Ball Mill Liner Design - Mineral Processing & Metallurgy

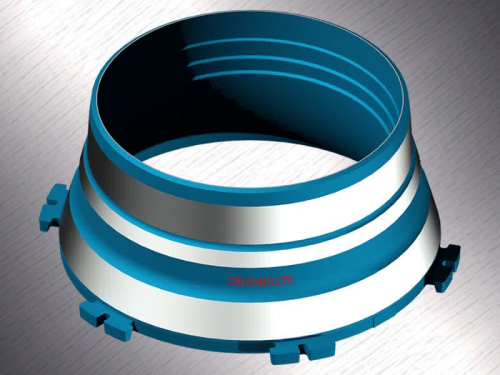

Rubber liners of the integral molded design follow the cast metal design. If using the replaceable lifter bar design in either metal or rubber the number of lifters should be about 3.3 π D in meters (for D in feet* divide 3.3 π D by 3.3) with the lifter height above the liners about twice the liner thickness.

Learn More

Polycorp - Ball Mill Liners

Ball Mill Liners. We are regularly supplying rubber liners up to 26 ft diameter ball mills. We design liners to optimize power for maximum throughput and increased liner life. These liners are

Learn More

Rubber Liner > ATEMS

Rubber Liner for Ball Mill (Overflow & Grate Discharge) / Batch Mill/ Continuous Mill- Lifter Bar (with Aluminum or without Aluminum), Shell Plate, Head Plate, Filling Segment, Manhole Plate, Drain Hole Plate, Centre Cone, Centre Plate, Discharger & Trunnion. Industry- Mining, Ceramic, Light weight brick manufacturing, Power Plant (FGD Mills

Learn More

Mill Liners,Grinding Ball / Rod Mill Shell / Rubber Liners - WALKSON

Mill Liners WALKSON, as a reliable mill liners manufacturer, can provide a wide range of wear resistant products for mineral processing industry, such as rod mill liners, grinding mill liners, ball mill shell liners and rubber mill liners; our main products include: SAG mill liner AG mill liner Chute line Hammer Shoe hammer of VSI Crusher

Learn More

Head Plate Liners Manufacturer,Head Plate Liners Exporter,Supplier

These liners are manufactured at our advanced manufacturing unit by utilizing the best grade raw materials and modern machines. The offered liners are used in mixing drum, slag mill, batch mill etc. for sealing purposes. In addition to these, our clients can get these Rubber Ball Mill Liners at reasonable prices. Features: Low maintenance

Learn More

Rubber - Growth Asia

In conventional Mill Lining Systems, Growth Rubber offers a full range of rubber SAG Mills; AG Mills; Primary & Secondary Ball Mills; Regrind Mills

Learn More

Ball Mill rubber Liner| Ball Mill Rubber Lining

Our Ball Mill Rubber Liners are designed to avoid unnecessary downtime and service intervals which results in easy inventory control and reduces the grinding cost. Sakar's Ball Mill Rubber Liners are design by using state-of-the-art software-driven with industry-leading inspection data, achieving an optimal charge trajectory and rate of wear

Learn More

Rubber mill liners - Outotec

Outotec rubber mill liners are tailor-made and developed in close collaboration with our customers. Being the pioneer, Outotec rubber mill

Learn More

Ball Mill / SAG Mill Steel Shell Liners - Unicast Inc

Longer Wear Life: Unicast Rubber Liners are pressure molded to ensure highest density and engineered for maximum abrasion resistance. · Reduced Weight Lowers

Learn More

China Rubber Liner,Cement Ball Mill Liner Plate,Abrasion Resistant

Ball Mill Rubber Liner Rubber Liners are used in grid type, overflow type, multi-warehouse-type ball mill. Abrasion Resistant Rubber Liner is mainly applied to wet grinding process, and now dry grinding which required strict metal impurities (iron) has also being applied. Ball Mill Spare Parts

Learn More

Polycorp - Rubber Liners

Polycorp has supplied complete rubber linings in some of the largest ball mills in South America at 26 feet in diameter. We have supplied Rubber Liners for more than 400 mills worldwide.

Learn More

Ball Mill Liners - Door Gasket Manufacturer from Ahmedabad

Our offered Ball Mill Liners are created to ensure maximum lifespan and performance of ball mill, with a selection of rubber and rubber composite liners availability.

Learn More

Ball mill Rubber lining | Ball mill Rubber liner manufacturer in india

BALL MILL RUBBER LINER Our Products » BALL MILL RUBBER LINING Ball Mill - Rubber Lining Ball Mill Rubber Lining Parts like Shell Lifter Bar, Shell Plate, Filler Ring, side shell Plate, center rubber circle, T bolt with nut, M.S. washer and rubber washer and side lifter Bar etc. for Ceramic Ball Mill. Advantage of Ball Mill Rubber Lining

Learn More

The Selection and Design of Mill Liners

Mill linings, Weir Rubber Engineering, Salt Lake City, UT 84126, United States of America . ABSTRACT . Dramatic shortcomings of mill liner designs, especially of large SAG mills, - such as rapid failure and High–low double wave ball mill liners –

Learn More

Compare the Benefits of Steel VS Rubber/Poly-Met Mill Liners | When is

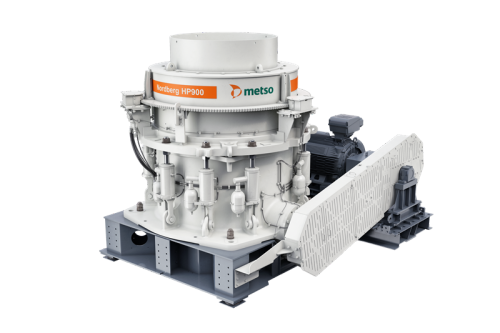

A mill liner arrangement (steel or rubber) with lifter bars to tall or too close to each other will cause reduced tonnage for lost of cascading action due to material packing between liners. Rubber liners do not perform that good under "impact" but good for abrasion. http://www.metso.com/

Learn More

China Rubber Ball Mill Liners manufacturers & suppliers

Manufacturer/Factory,Trading Company,Group Corporation; ISO 9001, ISO 9000, ISO 14001, ISO 14000, ISO 20000, OHSAS/ OHSMS 18001, IATF16949, HSE, ISO 14064, QC 080000

Learn More

Mill Lining Systems | FluidHandling - Trelleborg

Trelleborg has a wide range of rubber lifter bars and plates for ball mills, rod mills and drum scrubbers. Our MILLTOUGH® EXTREME composite lifter bar is

Learn More

Elastic polyurethane Mill liners - Eurogomma

Comparative test between premium quality Rubber liners and EUROGOMMA elastic Ball mill Rod mill SAG mill elastomer lining polyurethane lining wear

Learn More

Home [ballmillrubberliner.com

Perfact bonding with metal Core Optimm Tensile Strength & Elongation Prompt delivery as per Schedule Our Products SHELL LINER Ball mill shell liners are used to protect the inner shell of cylinder from being impacted and worn directly by material and grind-ball. At the same time we can use different forms of the shell liners Read More

Learn More