ball mill liner

Mill Liners Manufacturer - MGS Casting

Ball mill liners from MGS Casting maximize the lifespan and performance of your ball mill, with a selection of rubber and rubber composite liners available. Refined through ongoing design improvements, our ball mill liners maximize uptime and service intervals while providing an improved crushing of the ore. Our ball mill liners solutions can

Learn More

Elastic polyurethane Mill liners - Eurogomma

Elastic polyurethane Mill liners · Polyurethane Lifter bars · Polyurethane Shell liners · Polyurethane Head liners and grates.

Learn More

How to Replace the Ball Mill Liner?

At this time, it is necessary to replace the new ball mill liner. The ball mill liner is intended to protect the barrel of the ball mill in

Learn More

PDF IG PERFORMANCE PARTS Mill Liners for Ball Mills Increase ... - FLSmidthPDF

Your mill liner has a critical role to play in the performance of your ball mill - which is why you. need a liner that is perfectly designed for your grinding application. Whether you need step and wave liners that optimise your coarse grinding operation or corrugated and classifying liners that improve fine

Learn More

Ball mill liner - Wear Parts For Industry | Qiming Casting

Ball mill liners are the main replacement wear parts for ball mills. These liners are manufactured by wear-resistant material and rubble.

Learn More

BALL MILL LINER -PRODUCT - HUIHE MININGPARTS CO

HUIHE MININGPARTS CO., LTD - Mill liners is used in the steel ball mills/rod mills to protect the body of mills and also designed

Learn More

Mill Liner plate - mill linings Latest Price, Manufacturers

These liners are used in Ball mills where low contamination is required. Contamination with Alumina Ceramic lined ball mill is low due to their extremely low

Learn More

Rubber Ball Mill Liner - Strudex Mining

What is rubber ball mill liner? The ball mill liners are located on the inner surface of the ball mill barrel, which protects the barrel from the direct impact and friction of the grinding media

Learn More

Polycorp - Ball Mill Liners

These liners are custom designed for your mills. Mining, Ball Mill Liners, PolyStl™ Liners, PolyStl™ liners are composite of Special Wear Resistant Steel and High Pressure Moulded

Learn More

Home [ballmillrubberliner.com

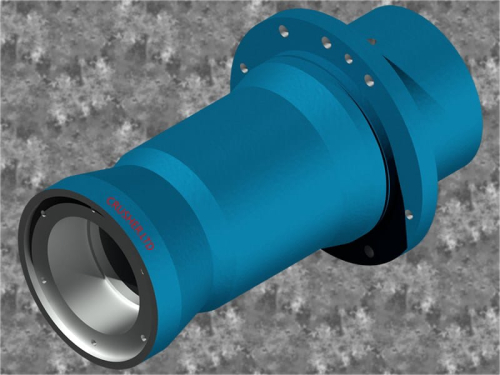

This product is an important part for conical ball mill and its call "feed end liners for ball mill' its main function is to protect the end cover of ball mill. The high wear-resistance head liner Read More . SIDE WALL CIRCLE. This product is also call blind disk for Ball Mill. It is a round plate which has all of the relevant bolt holes but

Learn More

Steel Ball Mill Liners

In Φ2.2 x 6m ball mill, the capacity is 3.2mt per hour on 2μm∼10μm, which has achieved leading level at home and abroad. In 2000, we designed the first set of the boltless liners applied in a super fine powder vibrating mill in China. In 2003, we designed and manufactured ball mill liners used in the largest super fine powder ball mills

Learn More

Ball Mill / SAG Mill Steel Shell Liners - Unicast Inc

Ball Mill / SAG Mill Steel Shell Liners Unicast Shell Liners are cast in materials ranging from chrome-moly steels to high chrome white iron. A minimum

Learn More

3 Reasons and 4 Improvement Measures for the Wear of Ball Mill Liner

Jun 24, · The application range of the ball mill is very wide. It is used in the field of metallurgy, chemical industry, construction, mineral processing and so on. The liner plays a decisive role in the

Learn More

Ball mill liner - WALDUN

Ball mill liner. Ball mill liner is used to protect the cylinder so that the cylinder from the abrasive body and material direct impact and friction, but also use different forms of the liner to adjust the movement of the grinding body state, to enhance the grinding body of the material crushing effect, help improve the grinding efficiency of the mill, increase production, reduce metal

Learn More

Ball mill Rubber lining | Ball mill Rubber liner manufacturer in

Rubber mill liners rubber's property has high abrasion resistant so that liners life is longer then conventional liners. 6. Less Maintenance: Rubber mill liners are give long service increasing the interval time between maintenance. 7. Reduced Voice and Vibration: Rubber mill liners reduce the voice level to pollution control level.

Learn More

Ball Mill rubber Liner| Ball Mill Rubber Lining

Our Ball Mill Rubber Liners are designed to avoid unnecessary downtime and service intervals which results in easy inventory control and reduces the grinding cost. Sakar's Ball Mill Rubber Liners are design by using state-of-the-art software-driven with industry-leading inspection data, achieving an optimal charge trajectory and rate of wear

Learn More

The effects of lifter configurations and mill speeds on the mill

materials, which are utilized for mill liners and grinding balls. liner spacing and detrimental ball-on-mill impacts is potentially decreased by

Learn More

Mill Lining Systems | FluidHandling - Trelleborg

Trelleborg has a wide range of rubber lifter bars and plates for ball mills, rod mills and drum scrubbers. Our MILLTOUGH® EXTREME composite lifter bar is

Learn More

The Different Types of Mill Liners You Should Know

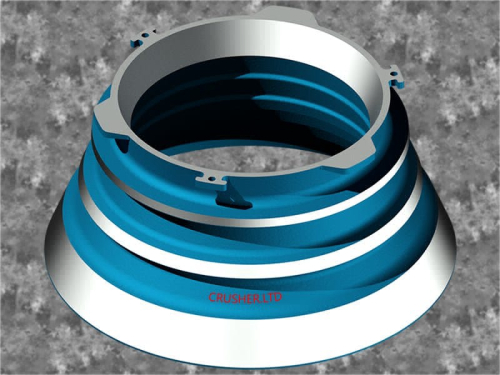

All ball mill liners must be very resistant and capable of withstanding high impacts. The milling process uses steel balls to break down the material. The grid liner has the dual role of protecting the cylinder while making the movement of the steel balls effective. Double Wave Liners People also use double wave liners for ball mills.

Learn More

Mill liners - Outotec

Mill liners optimized to meet your targets · Steel, Poly-Met™, Megaliner™, Rubber and Orebed™ mill liners for all mill types · Performance targets: · Continuous

Learn More

Ball Mill Liner Function - Wear Parts For Industry | Qiming Casting

Ball mill liner plays a major role in protecting the inner wall of the anchor windlass. Different shapes of the ball mill lining plate can improve the grinding effect of the ball mill and improve the working efficiency of the ball mill. 1, flat ball mill liner, the surface smooth, suitable for installation in the fine grinding warehouse.

Learn More