jaw crusher shaft

In- depth - Components of a Jaw Crusher | PROPEL INDUSTRIES

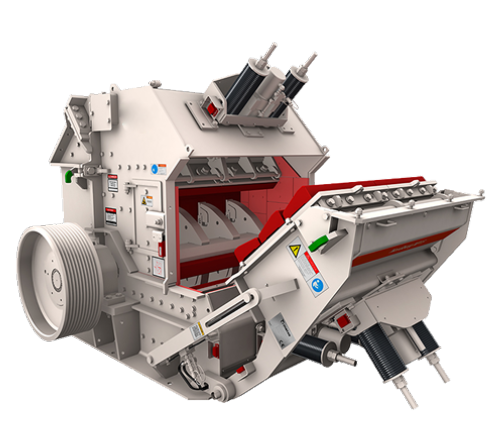

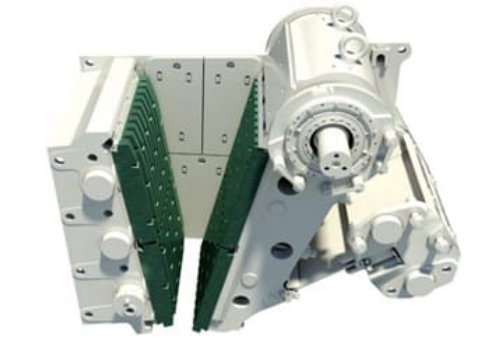

A jaw crusher consists of Crusher Body Pitman Jaw plate Rear end frame Eccentric shaft Flywheel Jaw crusher bearings Toggle plant Retraction spring and screw rod Check plate Setting adjustment 1. Crusher Body The design of the crushing body ensures that it is capable of exhibiting resistant to bending stress even when the crushing hard materials.

Learn More

The Most Practical Jaw Crusher Repair and Maintenance Manual

Eccentric shaft (pitman bearing): It is behind the moveable jaw plate, and together with flywheel with toggle plate to create a motion. So, the most important thing you must do is keeping a regular lubrication to eccentric shaft, or you will spend more than four hours in changing a new one when it is broken.

Learn More

Crushers - All crusher types for your reduction needs - Outotec

There are two basic types of jaw crushers: single toggle and double toggle. In the single toggle jaw crusher, an eccentric shaft is on the top of the crusher. Shaft rotation causes, along with the toggle plate, a compressive action. A double toggle crusher has two shafts and two toggle plates. The first shaft is a pivoting shaft on the top of

Learn More

Cause Analysis and Problems Solving of Jaw Crusher

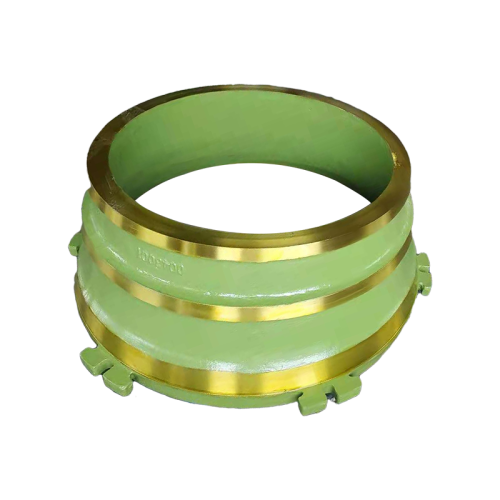

3The eccentric shaft tightening bushing is loose, causing no gap on both sides of the bearing housing of the frame,

Learn More

MEKA Jaw Crushers - Berkshire Engineering Supplies

MEKA Jaw Crushers are designed for cost-efficient primary reduction of hard/abrasive materials. Deep crushing chamber design maximises the feed size,

Learn More

GME10 - Jaw Rock Crusher - Global Mining Equipment

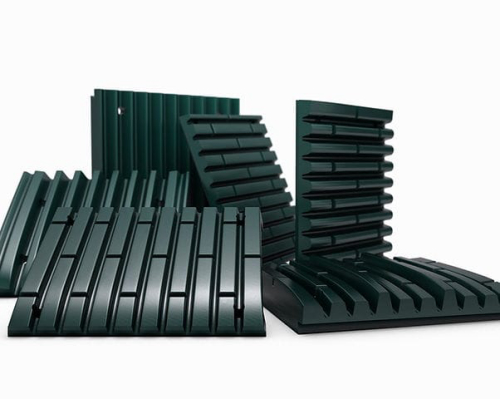

The shaft is 2.4" (60mm) at the cam shaft and 2" (50mm) at the drive shaft; The jaw rock crusher wear plates are 3/4" (19mm) and are made of a hard faced 450 Brinnel Hardness Material. Also available is an upgraded cast manganese / chrome wear plates. Specs: Drive System: 20HP Gas Engine / 18HP Diesel Engine / 10HP Electric Motor; Height: 48

Learn More

What is a Jaw Crusher? - MEKA Crushing Equipment

Jaw crushers are generally defined by their opening size. For example, a 900x650 mm crusher refers to a crusher with an inlet measuring 900 mm by 650 mm. The main parts and main technical parameters of a jaw crusher are presented below. 1. Feed Chute 2. Drive Flywheel 3. V-belts 4. Electric motor 5. Motor Stand 6. Settings and Damping Group 7.

Learn More

Jaw Crusher From American Pulverizer

Reversible manganese jaw dies for maximum wear life. Large, spherical, self-aligning roller bearings. Isolated, close running annular/labyrinth seals protect bearings from dust and water. Removable pitman/bearing assembly for maintenance ease. Steep pitched toggle plate for maximum horizontal pitman movement. Hydraulic or manual shim adjustment.

Learn More

how a jaw crusher works

How jaw crusher works. 1. The crushing mode of the jaw crusher is a curved extrusion type. Its main working part is two jaw plates, fixed jaw plate (fixed jaw) and movable jaw plate (movable jaw). The crushing space is formed by the jaws. 2. The belt and pulley are driven by an electric motor to move the movable jaw up and down through an

Learn More

Jaw Crusher Components & Parts - Mineral Processing & Metallurgy

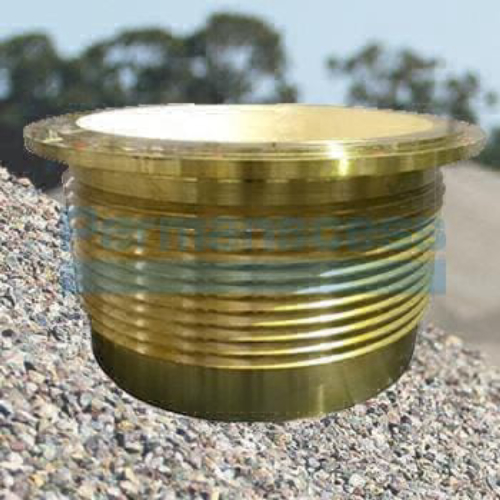

The first component of the crusher is the drive motor. This will drive a reducer sheave that is attached to an eccentric shaft. On the other end of the shaft is the flywheel. The purpose of the flywheel is to generate energy in the form of motion.

Learn More

Jaw Crusher Shaft And Bearing Removal Technique

1.5.9 Jaw Crusher Eccentric Shaft Bearings: There are typically four Shaft and bearings Massive rigid eccentric shafts made from steel along with roller bearing European Type Jaw Crusher- Heavy Industry adjustment methods eccentric shaft is processed by forged mold. All of these make the JC series jaw crusher

Learn More

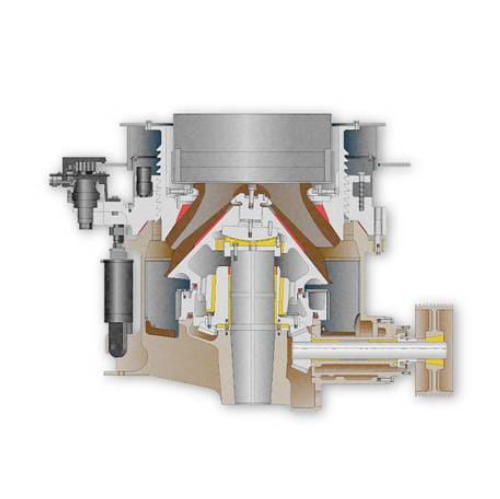

Gyratory Crusher - an overview | ScienceDirect Topics

A gyratory crusher includes a solid cone set on a revolving shaft and placed within Similar to jaw crushers, the mechanism of size reduction in gyratory

Learn More

What Are Jaw Crushers and How Do They Work? | Oreflow

These types of equipment come with heavy-duty and light versions that are built with stainless steel housings. The eccentric shaft is made of

Learn More

Jaw Crusher | Crushing Plant | Hard Rock Mining Equipment | DOVE

DOVE Jaw Crushers are supplied in large range of two models for Laboratory (0.550 – 3.0 TPH), and sixteen models (4.5 – 1000 TPH), for major rock crushing applications in Mining, Construction and Aggregates, Solid Waste processing,

Learn More

JAW CRUSHER SERIES - Mining and Rock

The jaw crusher above is designed for the motor sizes listed in RPG and technical specifications. This W2, Width shaft (mm) 1,882 1,882 2,093 2,336 n/a W3, Width cylinder (mm) n/a n/a n/a 2,571 2,569 D, Flywheel diameter (mm) 1,605 1,300 2

Learn More

Trio® CT Series Jaw Crushers - The Weir Group

Extra-large, drop-forged and heat treated overhead eccentric shafts. Compared to other jaw crushers, the Trio® CT Series jaw crusher has a robust design and

Learn More

Jaw Crusher | manufactor | thyssenkrupp Mining Technologies

Single-toggle jaw crushers are ideal for maximum throughput rates when crushing medium-hard and hard materials. They are characterized by the swing jaw being suspended directly on the

Learn More

Jaw Crusher Shaft - Sino Coalition

Our company sticks to the principle of "Quality is the life of the company, and reputation is the soul of it" for Jaw Crusher Shaft, Belt Conveyor Products , Conveying Pipe , Snub Roller Conveyor , Head Pulley On Conveyor . We are able to customize the solutions according to your needs and we can easily pack it for you when you purchase.

Learn More

Vertical Shaft Impact Crusher

Sanat Crusher Payam. Vertical Shaft Impact Crusher. Manufactured with advanced technology to ease operation and maintenance. Category: Crusher.

Learn More

Jaw Crusher Shaft - Manufacturers, Suppliers, Factory from China

Jaw Crusher Shaft - Manufacturers, Suppliers, Factory from China Our firm aims to operating faithfully, serving to all of our shoppers , and working in new technology and new machine regularly for Jaw Crusher Shaft, J 1160 Jaw Crusher , Jm806 Cheek Plate , Jaw Crusher Used , Q1340 Blow Bar .

Learn More

Jaw Crusher Manufacturer | Propel Industries

JAW CRUSHERS AVJ SERIES Propel AVJ series single toggle Jaw Crusher offers maximum possible fatigue strength and best reliability with various mounting possibilities. Details may

Learn More