how to size a cone crusher

Cone crusher by SIEBTECHNIK TEMA. Crushing & milling

Technical specification ; Feed particle size, mm, 25, 25 ; Final particle size, mm, 2 - 10, 2 - 10.

Learn More

How To Adjust Cone Crusher Gap

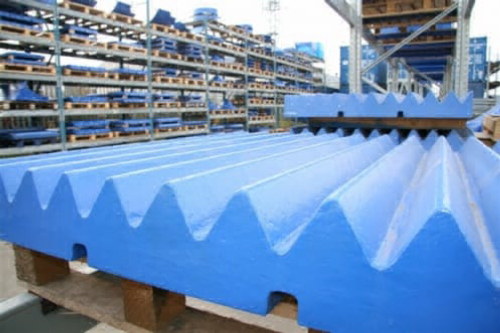

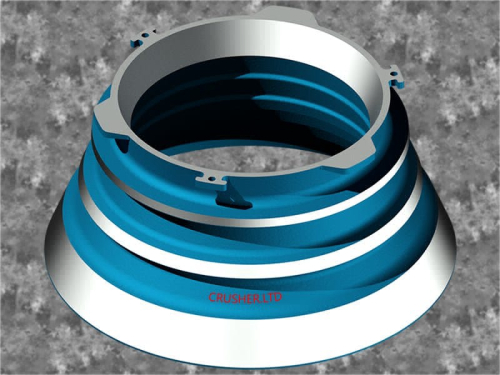

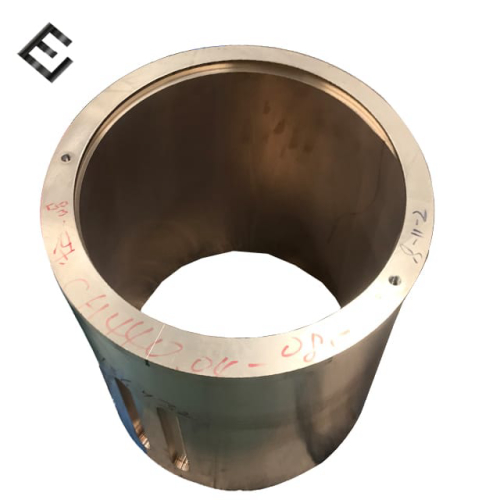

To complete jaw crusher liner replacement should to avoid damage in cutting cone plate process when the cone lining plate installed the adjustment ring cone at the lower part of the lower lining keep the gap between 1 2 mm between the plate and the cone lining the top installed should be first nut is installed and then cast zinc alloy.

Learn More

CONE CRUSHERS - Dynamic Equipment

DYNAMIC EQUIPMENT CONE CRUSHER RANGE ; DYNAMIC SPRING CONE CRUSHER · Sizes available: 2ft; 3ft; 4ft & 4 1/4ft; 5 1/2ft; 7ft ; DYNAMIC HIGH CAPACITY CONE CRUSHER.

Learn More

FAQ Of Cone Crusher - JXSC Mine

The liner as the easily damaged parts of the cone crusher, if it was evenly worn down to about 2.5cm, we should consider replacing it. Because the liner made of manganeses will crack when it about 1.6-1.9cm thick. Then causing the lining plate to

Learn More

Stationary Cone Crushers Market Size In 2022 : Strategic Plans by

Stationary Cone Crushers Market Research Report is spread across 113 Pages and provides exclusive data, information, vital statistics, trends, and competitive landscape details in this niche sector.

Learn More

How to Evaluate/Estimate a Crusher Product Size - Crushing, Screening

On the contrary to cone crushers, gyratory crushers have a small cone angle, which locates the contact zone between particles and crushing elements at an upper area of the chamber, not at the bottom. This implies that the limited number of comminution events (1 single rock probably will get at most 2 strokes before exiting the gyratory) in a

Learn More

Calibration and Validation of a Cone Crusher Model ... - MDPI

Accurate dynamic models of a mineral processing plant are helpful in control system development, equipment sizing, and operator training [1].

Learn More

How to Evaluate/Estimate a Crusher Product Size - Crushing

On the contrary to cone crushers, gyratory crushers have a small cone angle, which locates the contact zone between particles and crushing elements at an upper area of the chamber, not at the bottom. This implies that the limited number of comminution events (1 single rock probably will get at most 2 strokes before exiting the gyratory) in a

Learn More

What Is a Cone Crusher and What Can It Do for You?

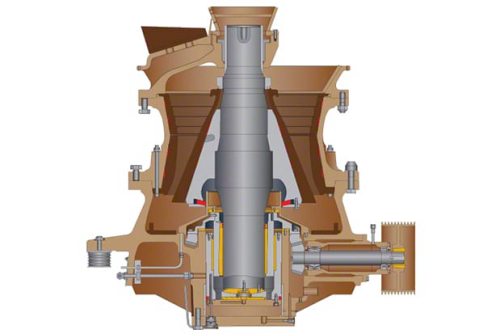

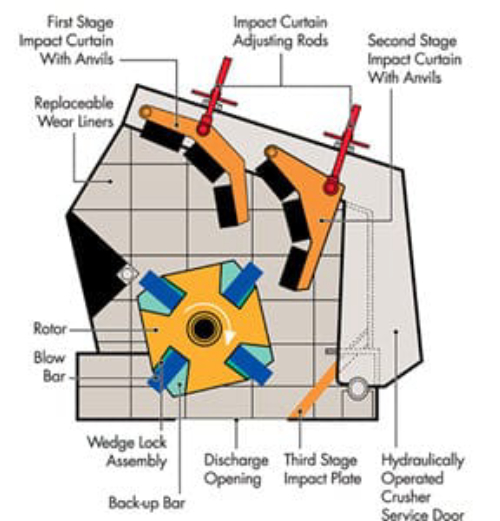

A cone crusher is one of many different types of crushers, like impact crushers, jaw crushers, and hammermills, that is used to process and reduce material like aggregates and construction and demolition waste. The cone crusher distinguishes itself from these other crushers by how it operates in processing material.

Learn More

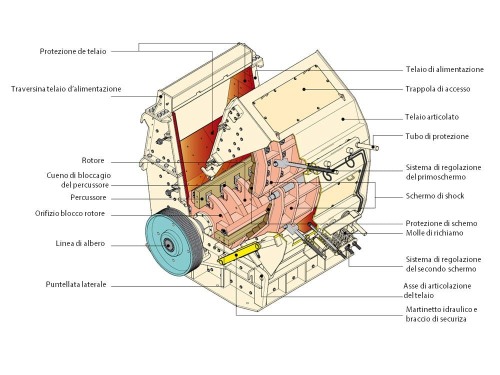

Jaw Crusher Explained - saVRee

Jaw crushers are sized based upon the dimensions of the top feed inlet (gape) or the dimensions of the jaws. For example, a 32 x 54 sized jaw crusher will

Learn More

Cone Crusher Configuration - How Setup Your Crusher For Optimum Performance

Since CSS is affected by we the mantle and concave it is important to measure and adjust frequently, in most cases daily. The CSS effect on gradation is as it becomes smaller the gradation gets finer, see Figure 6. Figure 6. Crusher operated on 16 mm, 18 mm, and 20 mm (from left to right curve).

Learn More

Cone Crusher Performance

For a given crusher, the factors depend on eccentric speed, closed side setting, rock material breakage characteristics and feed size distribution. The main

Learn More

How to maximize cone crusher performance

In most cases, cone crushers provide reduction ratios (the ratio of the feed size to the crusher vs. the size of the crusher discharge) of

Learn More

Cone Crushers | Crushing Plants | DOVE

Capacities are based on continuous regulated feed of clean, dry limestone of normal hardness with a bulk density of 16 ton/m3. Capacity may vary with the size and nature of the rock and the working conditions of the plant. DOVE reserves the right to modify the specifications at anytime, without prior notice.

Learn More

AMIT 135: Lesson 5 Crushing - Mining Mill Operator Training

Size is specified in terms of the gape and width, typically listed as gape x width. · Largest jaw crusher is 1600 x

Learn More

How to Evaluate/Estimate a Crusher Product Size

2) CSS - as noted above, use a Ball or "Slug" made of tin foil to drop through the lowest nip point with the crusher running. by rope. similar to gaping a cone

Learn More

Crushers - Thompson Tractor

A secondary crusher is one that takes crushed material out of a primary crusher and reduces the product further. An impactor or a cone crusher can be used as a secondary crusher. (6-8" feed size to ½" to 2" finished product). Cone Crushers are typically used as secondary crushers.

Learn More

Cone crusher basics in 4 minutes — SRP

The CH cone crusher can be calibrated to achieve specific results, maximize productivity and minimize wear, but any calculation will be undermined without a solid understanding of

Learn More

How To Adjust The Cone Crusher - mrsbonn

Cone crushers are only altered in the space between the mantle and side. These settings are called the OSS (open side setting) and CSS (closed side setting.) The gap on the side that is open determines the size of the largest particle of the finished product.

Learn More

Size reduction control in cone crushers - ScienceDirect

Cone crusher size reduction control (Itävuo et al., , Itävuo et al., ) was realized using a discrete-time I controller 2 in velocity form (Åström and Hägglund, 2006) to avoid the undesirable process upsets in case of measurement errors and measurement noise.

Learn More

How Do I Adjust A Cone Crusher? - Blogger

29/05/2022 · Cone crushers can be altered in the space between the mantle and the side. These settings are known as the OSS (open side setting) and CSS (closed side setting.) The size of the largest particle in the finished product is determined by the opening on the side that is open.

Learn More