jaw crusher jaw plate

Jaw Crusher MOVING JAW PLATE

In the jaw crusher running, the moving jaw plate attached to the jaw plate activities do tilting movement, and form an angle with fixed jaw plate for extrusion stone. price of jaw crusher moving plate in indiae The Shenbang product line, consisted of more than 30 machines, sets the standard for our industry.

Learn More

Jaw Plate - Toughing Crusher

Aug 03, · Description. Additional information. Introduction:Jaw plate is the main wear part of jaw crusher, which is divided into moving jaw plate and fixed jaw plate TOUGHING’s jaw plate

Learn More

Resminer Stone Crusher Jaw Plates - Wear Resistance Supplier in

One-Piece Stone Crusher Jaw Plate: Movable Jaw Plate: Make the first turn when 30% of wear occurs in the lower area. Make the second turn when 90% to 100% wear occurs in the new lower area. Replace the jaw plates after a further 30% of the wear occurs.

Learn More

C160 Crusher Jaw Plates - Hunan JY Casting

Aftermarket C80 Crusher Jaw Plates By Hunan JY Casting When it comes to C160 crusher jaw plates, Hunan JY Casting focuses on manufacturing those wear parts for a long time. Although

Learn More

Beaverton, OR - Crushers For Sale - Equipment Trader

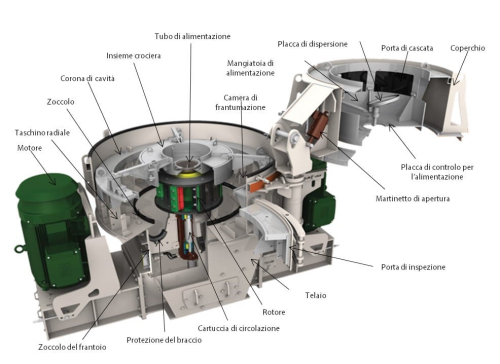

The three main types of crushers are the cone crusher, the jaw crusher, and the impact crusher. Make sure you understand all of the differences between these kinds before choosing one for your project. Regardless of which type of machine you choose, you should be prepared for some very powerful crushing power.

Learn More

Crusher Jaw Plate for Sale - EB Castworld % Crusher Jaw Plate

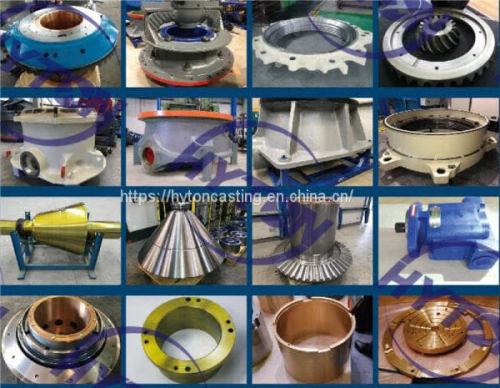

Type: Jaw Plate / Crusher Plate; Machine Type: crusher / Jaw crusher; Applicable Industries: Energy & Mining; Manganese Contents: Mn13Cr2, Mn18Cr2, Mn22Cr2, etc; Features & Advantages: Materials: High manganese or other materials as your requested. Use: Wear parts for crushers in the quarry, mining, construction and metallurgical industry

Learn More

EXPERIMENTAL EFFECT ON JAW CRUSHER PLATE - ijariie

Jaw crusher jaw plate overview:- Jaw plate is manufactured with super high manganese steel, therefore it has a service life 50~100% longer than those made of

Learn More

Crusher Jaw Plates For Popular Brands By Hunan JY Casting

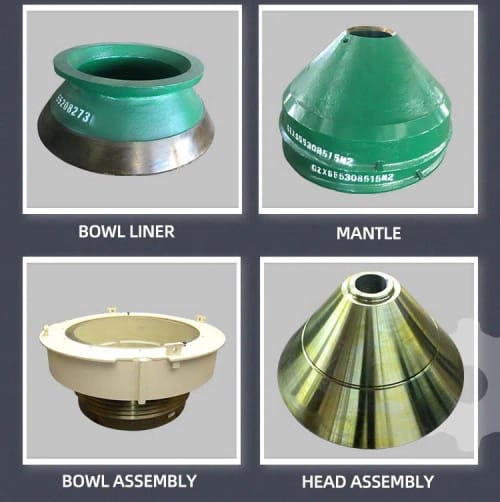

The crusher jaw plates are the main wear-resistant parts installed on the machine body to squeeze and crush the stone. Normally, it consists of a 1 piece fixed jaw plate and a 1 piece movable jaw plate. In order to rotate and exchange more easily, movable jaw plates also have 2 segments design and 3 segments design.

Learn More

Crusher Jaw Plate Latest Price, Manufacturers & Suppliers

Find here Jaw Plates, Crusher Jaw Plate manufacturers, suppliers & exporters in India. Get contact details & address of companies manufacturing and

Learn More

How to Choose the Right Jaw Plates for Jaw Crushers - Ware Resistance

A jaw crusher crushes stone or ore using large steel crushing plates (jaw plates) that move in two converging tracks with an adjustable gap width. Raw material enters at the top of these tracks, and as it slides down, it is squeezed by these plates until finally getting jammed as its size prevents further convergence.

Learn More

Jaw Crusher Wear Parts - Columbia Steel Casting Co., Inc

Columbia Steel manufactures the world's largest number of jaw designs. Wear parts for all popular jaw crushers, include: jaw dies, cheek plates, and more

Learn More

Jaw Plate Price

Latest Technology Factory Price Mining Machine Parts Jaw Crusher Spare Parts Tooth Plate Jaw Crusher Liners For Mining Crusher. $1.83/ kilogram.

Learn More

How To Change Crusher Jaw Plate? - MGS Casting

Lift the new jaw plate, and start the crane to hang the moving plate and the fixed plate separately. Install the clamps, place the clamps in place, and tighten the screws. Tighten the stationary plate screws and install the side plates. Adjust the gap of the discharge port. Start the jaw crusher and vibrate the mine for trial operation.

Learn More

What are the Materials of the Jaw Crusher Plates and Which is Better

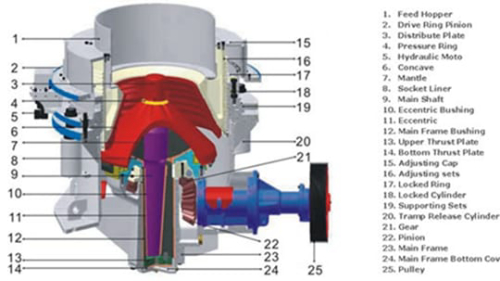

The structure of the jaw crusher is mainly composed of a movable Jaw Crusher Plates, a fixed jaw plate and an eccentric shaft. When the eccentric shaft rotates, the movable jaw plate mainly bears the squeezing action of the material, and the fixed jaw plate mainly bears the sliding cutting action of the material.

Learn More

Crusher Parts Jaw Plate Tooth Plate Suit for C125 Jaw Crusher

Certification: CE, RoHS, ISO 9001:2000, ISO 9001: Standard: ASTM Surface Treatment: Polishing Manufacturing Process: Casting Material: High Manganese Steel Descripition: Crusher Jaw Plate

Learn More

Source The Ideal Wholesale jaw crusher plate

Create fine powders for industrial projects with crusher machines. Browse the jaw crusher plate range on for all types at wholesale prices.

Learn More

Jaw Plates - John Moore Wear Parts UK

Jaw plates of varying manganese contents are also available; 13/14%, 18% and 22%. Powerscreen Premiertrak 400/R400 Jaw Crusher Box.

Learn More

Jaw Crusher | Crushing Plant | Hard Rock Mining Equipment | DOVE

DOVE JAW CRUSHER FEATURES: High tonnage capacity of up to 1000 Tons/ Hour, and low operating cost. Designed for toughest rock material, with compressive strength of up to 320 MPa. Supplied for Primary coarse crushing and secondary Fine crushing, within the rock reduction plant. Wide range of closed side setting adjustment.

Learn More

Jaw Plates - Emerald Parts

Emerald Parts - Jaw Plates Our company actively offers jaw dies, cheek plates, and hardware 0305450053 - 30 x 54 18% Manganese Fixed Jaw Crusher Plate.

Learn More

JAW CRUSHER SERIES

The nip angle is the angle between the fixed and moving jaw plates. Our CJ crushers have an optimum nip angle in the 16-23 degree range.

Learn More

jaw crushers for all your needs - Lutze Process

Low jaw plate wear. • Large feed acceptance capability. These four factors are closely linked and the jaw crusher provides a good balance. The de-.

Learn More