what is gyratory crusher

Part 03 - Gyratory Crusher

A Gyratory Crusher is a large crusher, using the gyratory sports in casing cone cavity of crushing cone to produce extrusion, fracturing,

Learn More

PDF) A Gyratory Crusher Model and Impact Parameters

The development of a gyratory crusher model was achieved in the following three main stages: mathematical representation and coding of the

Learn More

How do a gyratory crusher work?

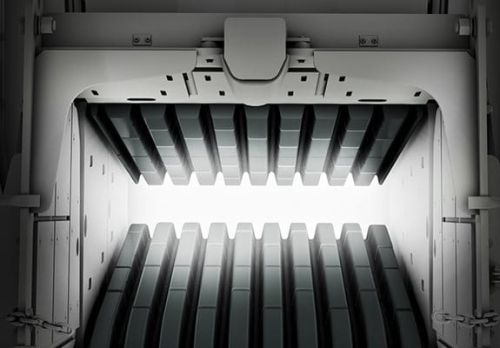

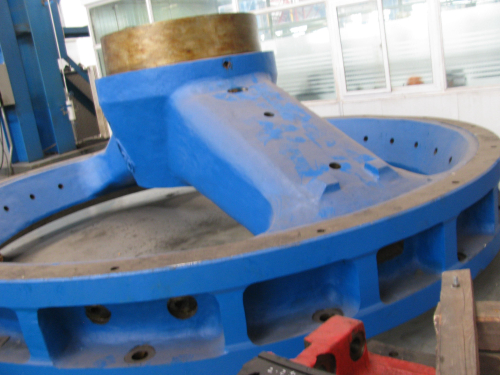

A gyratory crusher is similar in basic concept to a jaw crusher, consisting of a concave surface and a conical head with both the surfaces are typically lined with manganese steel liners. The inner cone has a slight circular movement, but it does not rotate. The movement is generated by an eccentric arrangement.

Learn More

What Are the Differences Between The 7 Types of Crushers?

Jaw rock crusher VS gyratory crusher Different crushing principles Jaw crusher is a compression type of crushing machine. The flywheel works together with eccentric shaft and toggle plate provides a motion which pushing moveable jaw plate towards stationary jaw dies, and during the process, a compressive force squeezes raw material.

Learn More

construction of gyratory crusher

15/09/2022 · WhatsApp: https://wa.me/8613621919955?text=Pls+send+us+this+message+first%2C+then+we+will+arrange+for+the+right+sales+engineer+to+serve+you%21+Your+Unique+Co

Learn More

Gyratory Crusher Services I Service - thyssenkrupp Mining Technologies

Detect and rectify faults at short notice through the analysis of your plant's operating and process data. Visualization of crusher KPIs and analytics results (trends, prognosis, machine conditions, wear analysis and more) Identify process and operation improvements. Benchmarking for evaluation of improvement potentials.

Learn More

Crusher - Wikipedia

Crushers may be used to reduce the size, or change the form, of waste materials so they can be more easily disposed of or recycled, or to

Learn More

Jaw Crusher VS Gyratory Crusher - JXSCMACHINE

The gyratory crusher is taller than the jaw crusher, thus needs a high workshop design. Besides, gyratory crusher is heavy than jaw crusher, it's not convenient to move. Capacity. Gyratory crusher can work continuously, has high productivity and crushing ratio ( up to 6-9.5), working performance is very stable, light vibration.

Learn More

Gyratory Crusher (TS) for harsh environments

The Gyratory Crusher TS is distinguished from other gyratory crushers by its revolutionary design which allows you to easily and safely perform major service and maintenance functions. It is designed so that you can easily access and remove the eccentric assembly, bushings and hydraulic piston through the top of the crusher, hence the name

Learn More

Crusher Close Side Settings - Mineral Processing & Metallurgy

17/01/ · Crushing angles may vary between the approximate limits of 22 and 30 degrees in a line of standard gyratory crushers. It is possible to use larger angles in the larger sizes of crushers because the greater weight of the individual pieces of material tends to minimize slipping. In these large machines, a difference of a few degrees in the

Learn More

Gyratory Crusher Pro | manufactor | thyssenkrupp Mining Technologies

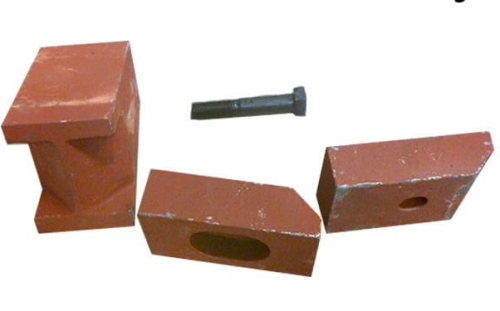

The main characteristic of jaw gyratory crushers is their enlarged feed opening which is located on one side of the crusher only. It is normally serrated and, together with the upper part of the mantle, it forms the initial crushing zone. The coarsely crushed material is then reduced to the desired product size in the crushing chamber below.

Learn More

CG830 Gyratory crusher — SRP - rockprocessing

CG830i crusher offer excellent reliability and safer & faster maintenance – up to 30% faster than competing crushers. A robustly designed one-piece main

Learn More

Gyratory crusher definition and meaning - Collins Dictionary

gyratory crusher in Chemical Engineering ; The · is a pot crusher with the rotating element set eccentric to the pot. ; The moving element of the · is a rotating

Learn More

Gyratory Crusher - an overview | ScienceDirect Topics

A gyratory crusher includes a solid cone set on a revolving shaft and placed within a hollow body, which has conical or vertical sloping sides. Material is crushed when the crushing surfaces approach each other and the crushed products fall through the discharging opening.

Learn More

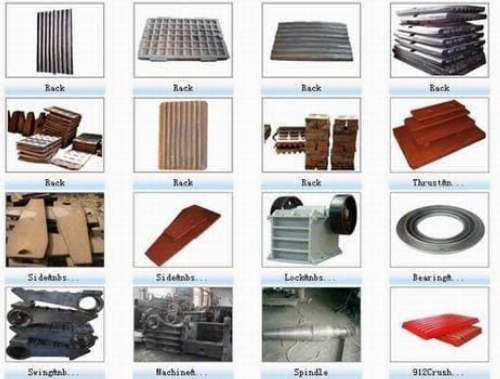

What Is Gyratory Crushers

Gyratory Crushers. Gyratory crushers feature a conical head and concave surface (often lined with manganese steel) and break apart material by compression through what is known as eccentric movement. Like jaw crushers, gyratory crushers are often utilized in primary crushing stations, though they may sometimes be used as secondary crushers

Learn More

Gyratory crushers - thyssenkrupp

thyssenkrupp gyratory crushers in primary crushing is second to none. KB 63-75 for aggregates. Capacity: 2,600 t/h. KB 63-89 for iron ore.

Learn More

Gyratory Crusher | Hazemag North America

A gyratory crusher is one of the main types of primary crushers in a mine or ore processing plant. Gyratory crushers are designated in size either by the

Learn More

Gyratory Crusher l Introduce, Working Principle - JXSC Mine

Gyratory crusher is a new type of crusher which can replace fine jaw crusher or cone crusher. The gyratory crushing equipment has a bright future in the

Learn More

Gyratory Crushers - Mineral Processing & Metallurgy

17/02/ · Gyratory Crushers. The primary rock breaker most commonly used in large plants is the gyratory crusher, of which a typical section is shown in Fig. 5. It consists essentially of a

Learn More

Superior™ MKIII Series primary gyratory crushers

Primary gyratory crushers are the initial driving force for the entire mineral processing circuit. Outotec's Superior™ MKIII primary gyratory crushers

Learn More

Difference Between Jaw Crusher and Gyratory Crusher - JXSC

The gyratory crusher is mainly used for coarse crushing various hard materials as primary crusher. But it is not suitable for crushing viscous materials. General the large-scale dressing mill uses gyratory crusher. Jaw crusher can crush high moisture, viscous ore, and not easily blocked. General the small-scale dressing mill and quarry mostly

Learn More