double roll crusher working principle

Double Roll Crusher | Henan Deya Machinery Co., Ltd

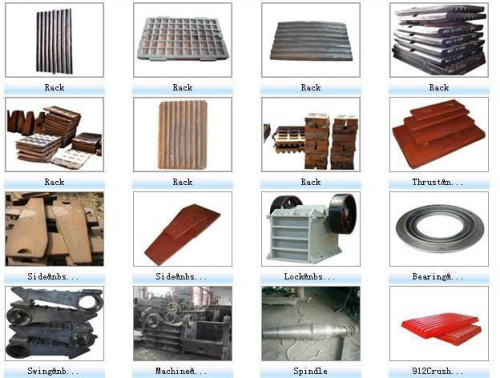

30/07/ · Double roll crusher working principle. Roll crushers, or crushing rolls, or double roll crushers, are still used in some mills, although they have been replaced in most installations by

Learn More

Roll crusher working principle & structure

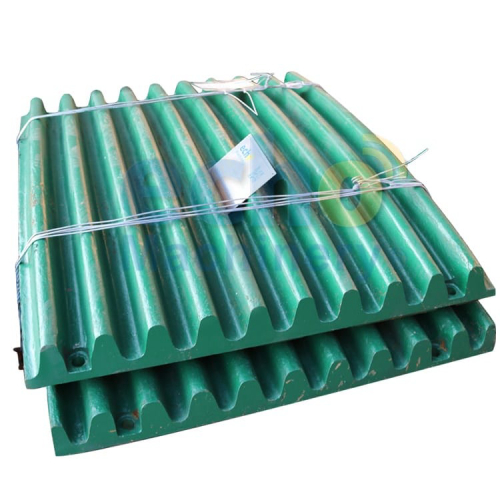

Double roll crusher is a commonly used roll crusher, whose structure is detailed in Figure 1. Its crushing mechanism is a pair

Learn More

Double Roll Crusher

Double Roll Crusher working principle: Double roll crusher consists of roll wheel, roll bearing, pressing device, adjusting device and driving device etc.

Learn More

Dual roll crushers, how they function - Mine Engineer

A roll crusher crushes using compression, with two rolls rotating about a shaft, towards the gap between the rolls. The gap between the rolls is set to the size

Learn More

Advantages and Disadvantages of Roll Crusher

The roller crusher, also known as double roller crusher , is suitable for medium and fine crushing. Its main component is toothed roll.

Learn More

Roll crusher working.how it work

This crusher consists of,a heavy cast iron frame equipped with two counter rotating rollers mounted on a separate horizontal shaft. The crushed rock from the primary crusher is fed through the gap

Learn More

The Working Principle Of Double Roll Crusher, Mobile Crushing Station

Working Principle Of Double Roll Crusher. brand Mobile crushing station is used and welcomed not only in China mobile crushers market but also world market. Hydraulic Cone Crusher. Hydraulic cone crusher, the latest generation of crusher in today's mining construction industry, can replace spring cone crusher and general hydraulic cone

Learn More

Double Roll Crushers | McLanahan

How Double Roll Crushers Work. Operating Double Roll Crushers is quite simple. Whether it is a single or dual drive arrangement, the rolls are powered by electric motors and V-belt drive configurations, resulting in reliable and quiet operation. If it is a single drive arrangement, power is transferred from the driven roll to the non-driven

Learn More

working principle of roll crushers

Roll Crusher Working Principle increasing efficiency by selective schematic showing the superposition principle for an oriented a double roll crusher is used for the compressive working group mining equipment and science experiments for middle school balloon rocket so what s the big deal about this lab it seems almost grade school level

Learn More

Double roller crusher

The two rollers of the roll crusher are moving towards each other for squeezing materials, the material is crushed between two rollers, and crushed product is

Learn More

How Double Roller Crusher Works 3D Animation Video

The material enters into the space between the two rolls, suffered both extrusion and shear force.In the crowd rolling, cutting and grinding, it is crushed into the required size and then sent by

Learn More

the working principle of double roll crusher

Working principle of Double roll crusher A roll crusher crushes using compression, with two rolls rotating about a shaft, towards the gap between the rolls. The gap between the rolls is set to the size of product desired, with the realization that the largest feed particle can only be 4 times the gap dimension.

Learn More

roller crusher working principle stone crusher machine

Double roller crusher is equipped with two crushing rollers The distance between two rollers can be adjusted According to the particle size required by the user

Learn More

what is the working principle of crusher

2. Crushers' Working Principle (1) Jaw crusher is the crushing equipment that uses two jaw plates to squeeze and bend materials to crush various hardness materials. The crushing mechanism is composed of fixed jaw and movable jaw. The material is crushed when the two jaws are close to each other, and the material smaller than the discharge gate

Learn More

The Working Principle of Double Roll Crusher

It is best suited for the intermediate and fine crushing in small and medium sized mine and chemical industry. The biggest compressive strength of crushed materials is 160Mpa. Roller crusher has advantages of simple structure, reliable work, low cost and less over-crush, it's suitable for crushing coal, coke, sinter and other medium hardness

Learn More

Working Principle Of Smooth Roll Crusher Compression

Double roller crusher working Principles: Click & Chat Now. roller crushing working – CGM Project Case. Working Principle of Roll Crushers: A roll crusher crushes using compression, with two rolls rotating about a shaft, towards the gap between the rolls. Click & Chat Now. building up roll crushers – beltconveyers.net.

Learn More

The Working Principle Of Double Roll Crusher

Working Principle of Double roll crusher. A roll crusher crushes using compression, with two rolls rotating about a shaft, towards the gap between the rolls. The gap between the rolls is set to the size of product desired, with the realization that the largest feed particle can only be 4 times the gap dimension.

Learn More

Roll crusher,Hydraulic double-roll crusher,Cone crusher For

Working principle and structure · 1. This series of roller crushers are mainly composed of rollers, roller supporting bearings, pressing and adjusting devices,

Learn More

Gundlach Multi Roll Crusher | PDF | Bearing (Mechanical ... - Scribd

Gundlach Multi-Roll. Crushers HANDLING A WORLD OF MATERIALS Gundlach Roll Crushers. Designed to precisely crush to product size and with maximum yield Our heavy-duty Gundlach Crushers roll crushers are designed with breakthrough 3-D crushing technology that includes intermeshing continuous tooth roll design and positive roll timing that delivers the industry’s

Learn More

Things You Should NEVER Do While Operating Double Roll

Smooth double roller crusher Usage and features and working principle. Today double roller crusher is utilized for crushing ore, coal, cement, glass, silicate

Learn More