types of crusher run

Calculate Crusher Run | cubic yards / Tons - Gravelshop

Calculate Crusher Run. Type in inches and feet of your project and calculate the estimated amount of Base Material in cubic yards, cubic feet and Tons, that your need for your project. The Density of Crusher Run : 2,410 lb/yd³ or 1.21 t/yd³ or 0.8 yd³/t. A:

Learn More

7 Different Crushed Stone Sizes and Their Applications - ReAgg

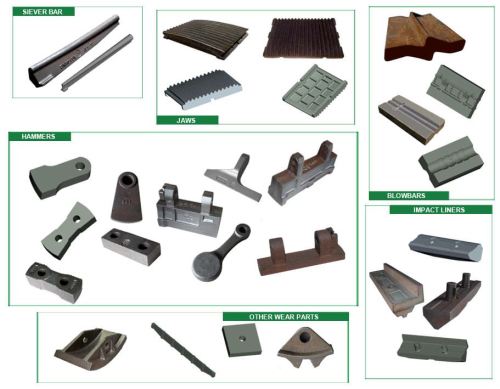

5 - Crushed stone #5 is 1 inch or smaller in size. This material is perfect for road and paver base. #8 - These stones are between 3/8 and 1/2 inch long. It is the most common stone used for concrete mixes. #10 - Crushed stone #10 is known as screenings or dust. Most use this material to create pavers and concrete blocks. Specialty Crushed Stone,

Learn More

How to Use Crusher Run for Driveway - YardOwner

Crusher run also referred to as quarry process stone, is a type of gravel that consists of coarse aggregate (crushed gravel) and fine aggregate (limestone dust). The crushed stone particles are typically ¾-inches in diameter, while stone dust particles are usually 1/8-inches wide or smaller.

Learn More

Crusher Run Gravel For An Amazing Driveway

In the US, the most common types of this material include a creek, bench, bank, and plateau gravels. Additionally, to make construction-grade gravel, the manufacturers need to gather large rocks and breaking them apart into small fragments. Thus, these can form a pliable surface but so durable. They get the big stones from mining at various places.

Learn More

Is there a Standard for "No. 2 Crusher Run" - Eng-Tips Forums

No.2 crusher run refers to #2 crushed stone with all of the stone dust froom crushing. #2 crushed stone is just the stone. In NY the state DOT has a spec for it, where it is also refered to as a Type 2 subbase. When we specify it we refer to the NYSDOT specifications. Recommending compaction effort and fill material is the specialty of

Learn More

Crusher Run Penang, Malaysia, Simpang Ampat Supplier

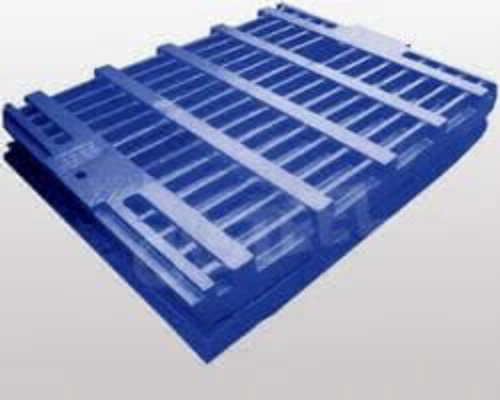

Crusher Run is a blended mix of coarse aggregate and fine aggregate. The combination of both crushed stone and stone dust creates a low void content (the

Learn More

crusher sizes in inches

What size is crush and run gravel? Crusher run, with its angular facets, allows greater interlocking and stability than smooth rocks. Crusher run is a type of

Learn More

Quarry Stone Types | Berryville & Winchester, VA - Stuart M Perry

crusher run stone #26d: 1″ x 100 mesh: dirty crusher run: #dt: 3″ dirty tailings: #rr ai & ogb: 3″ x 8″ stones between 25 & 75 pds: #rr i: 6″ x 12″ stones between 50 & 100 pds: #rr ii: 12″ x 24″ stones between 150 & 500 pds: #sr: shot rock: vdot pug mix road base stones #21b: 1 1/4″ x 100 mesh: clean stone minimum amt of fines

Learn More

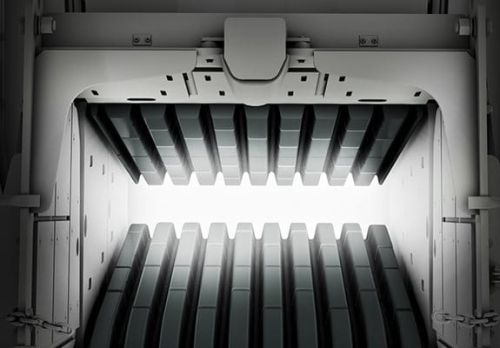

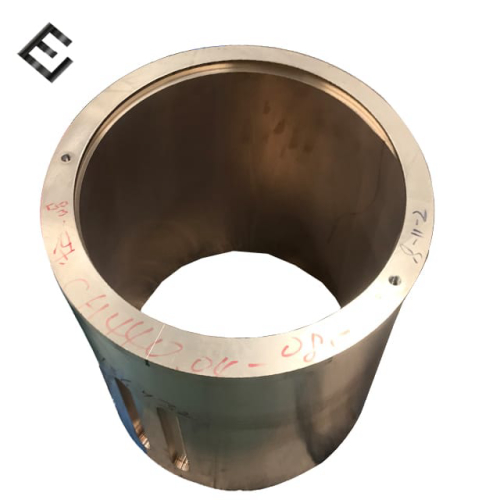

5 Types Of Stone Crushers | Application and Maintenance - JXSC Rock Crusher

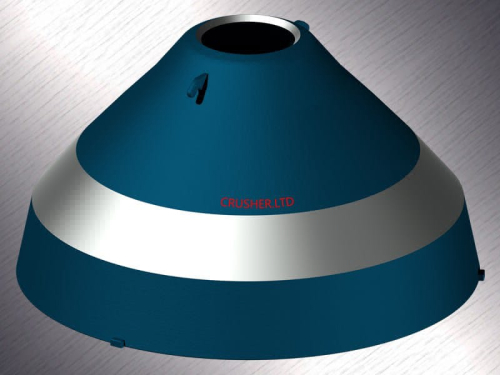

The jaw crushers run smoothly. When the vibration quantity of the machine suddenly increases, it should stop immediately to find out the cause. Types of cone stone crushers: GP cone crusher namely single-cylinder hydraulic cone crusher, HP cone crusher namely multi-cylinder hydraulic cone crusher, Compound cone crusher. Routine Maintenance

Learn More

Types of Crushers - Mineral Processing & Metallurgy

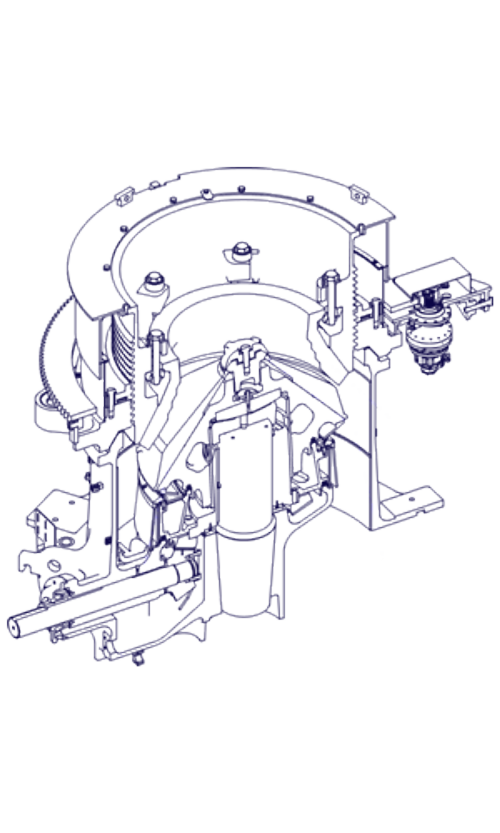

The gyratory and jaw crushers come under the first category, the crushing rolls under the second. Strictly speaking, the gyratory motion is not a reciprocating one, but it is so with respect to any vertical radial plane through the crushing chamber; therefore it is convenient to view it in that light.

Learn More

Crusher Run | Tarmac

Crusher Run or hardcore is a 40mm down to dust construction material that is commonly used as foundations for a range of surfaces. Manufactured from crushed rock and stone dust the crusher run or hardcore is blended to provide a low-void content that tightly locks together. Widely used for in construction, building, driveways, patios & footpaths.

Learn More

Crusher Run Near Me - Prices and Delivery - Gravelshop

Our most popular crusher run delivery is the 2" minus crusher run which is good for retaining walls, foundations, sheds, and much more. Its strength, durability, and good traction make it a perfect base material. If you are landscaping or renovating your property, you will have a lot to benefit from our crushed rock delivery.

Learn More

Aggregates - Riccelli-Northern

Crusher run – Crusher run gravel and limestone is typically used as a driveway topping and as a sub-base for blacktop, concrete, paving, and retaining walls. We

Learn More

Different types of crushers for distinctive needs - Outotec

Dec 17, · Impact crushers are traditionally classified into two main types, horizontal shaft impact (HSI) crushers and vertical shaft impact (VSI) crushers. These different types of impact crushers share the crushing principle, impact, to reduce the material to smaller sizes, but features, capacities and optimal applications are far from each other.

Learn More

What Type of Crusher Is Best for Primary Crushing?

Jaw Crusher. Primary crushers reduce large run-of-mine material, such as rocks and ore lumps, into smaller sizes for further processing

Learn More

Crushed Rock Types Of Crushed Rock | Crusher Mills, Cone Crusher

Crushed Stone Types. Contact Us 411 Crushed Stone 6220 U.S. 411 Greenback, TN 37742 Phone: (865)856-6611—–Serving Knoxville, Alcoa, Maryville, Vonore, Greenback .

Learn More

Crusher Run Bulk Bags & Poly Bags - Crush and Run | Corfe Stone

Crusher Run. £36.74 + Vat. Sold as: Required Bulk Bag Poly Bag. Quantity: Add to Wish List. Description. Area Calculator. Crusher Run, otherwise known as hardcore is a 40mm down to dust substance offering a great foundation for a range of surfaces. When spread this material can be compacted by aid of a wacker plate, to give an extremely solid

Learn More

How to Use Crusher Run for Driveway – YardOwner

Crusher run also referred to as quarry process stone, is a type of gravel that consists of coarse aggregate (crushed gravel) and fine aggregate (limestone dust). The crushed stone particles

Learn More

Crusher Run | Crush Granite, Hardcore & More - Marshalls

Marshalls range of aggregate products includes crusher run output in a number of different gradings from producing 6F5 crusher run material o 75mm

Learn More

Different types of crushing equipments - Constro Facilitator

May 06, · A Jaw Crusher is one of the main types of primary crushers in a mine or ore processing plant. The size of a jaw crusher is designated by the rectangular or square opening at the top of the jaws. Hammer-mill crusher; Rod mill crusher. Rod mills run along with the outside gear. Materials spirally and evenly enter the crushing chamber along

Learn More

The Complete Guide to Crushed Stone and Gravel - Gra-Rock

It begins with using a rock crusher in a quarry or site with plenty of large rocks. There are many types of crushers, but their main job is

Learn More