cone crusher liner selection

cone crusher liner selection | images of parts of hammer mill

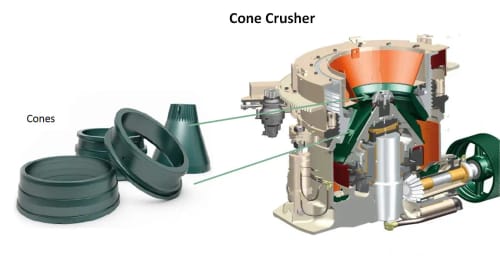

Cone Liner Profiles. •. Heavy Duty Cone Liners. cone crusher liner wear selection. Cone Crusher Liners Selection Cone crusher which is the most popular crusher type in the world than jaw crusher and impact crusher Cone crusher liners the mainly wear parts in cone crusher and also need exchange them very regularly In this post we will analysis

Learn More

Crusher Wear Parts Selection Guide For Cones, Jaws

2021. 8. 8. · The most important factor in Cone Crusher liner selection is the feed. You should have a well-graded feed going into the crushing chamber. A well-graded feed is generally

Learn More

Cone Crusher Liners For Popular Brands With Various Material

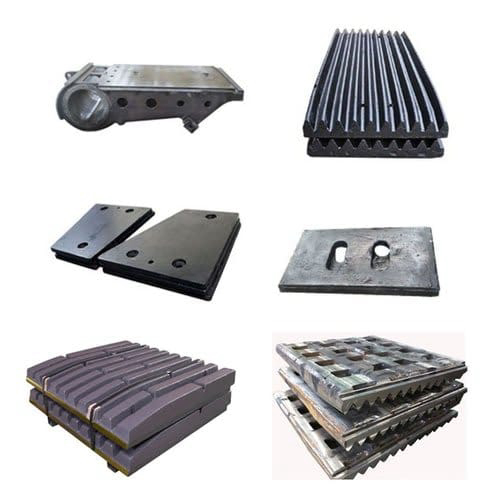

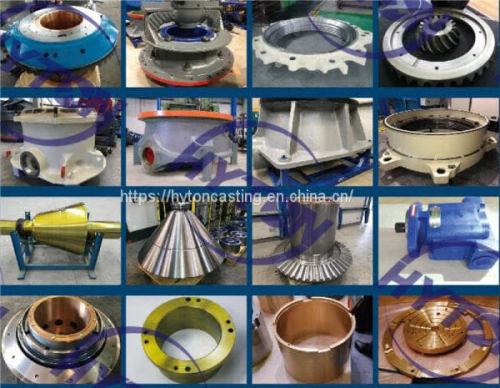

2 days ago · It is the outer sacrificial wear liner that sits inside the upper frame. Common Aliases: Cone crusher liners, Cone crusher wear parts, Manganese cone liners, Mantle and concave. Main Material: Mn14, Mn18, Mn22, Manganese alloy steel, Manganese steel with TIC inserts. Cast Methods: Lost foam casting, Sand casting, V-method casting.

Learn More

World-Leading Crusher Liners - CMS Cepcor

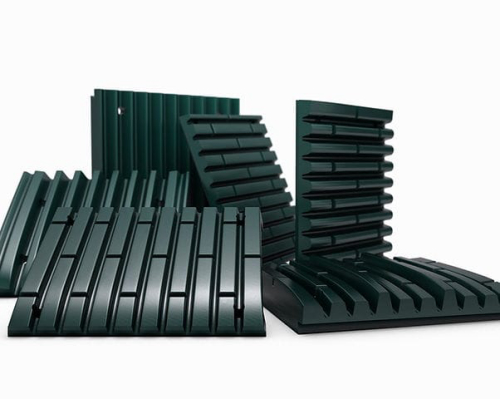

Cavity and liner selection. CMS Cepcor® stock a wide range of cavity liner options for cone crushers along with many jaw plate tooth profile options for jaw

Learn More

Cone Crusher Liners: How To Select And When To Change - Weebly

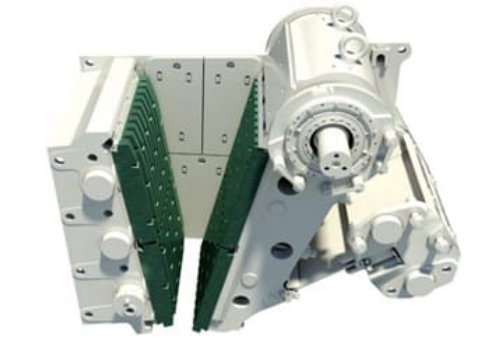

2022. 5. 14. · Cone Crushers have crushing chambers. It is the space between the concaves and the mantle, which is the steel piece that moves. Concaves and mantles are protected from daily wear by replaceable manganese liners. Selecting the Cone Crusher liner. There are many liners available for both fine and coarse feeds.

Learn More

Cone Crusher Resources - Corporation

To learn more or to purchase spare parts for cone crushers, Covers the cone head of the crusher to protect it from wear. Cone Liner Selection.

Learn More

Crusher Cone Liner Maneuvering

Cone crusher liner selection, which is very important selection for user. Cone crusher liners need periodic replacement to protect cone crusher and keep the

Learn More

How To Select Cone Crusher Liners and When To Change Them

2021. 12. 27. · The Cone Crusher liner should have a well-graded feed flowing into the crushing chamber. This generally consists of: 90 to 100 percent passing the closed-side feed opening.

Learn More

R Crusher Wear Parts Reference Guide

2018. 9. 15. · 2. Jaw Crusher Wear Parts 3.• Cone Crusher Wear Parts 4. Impactor Crusher Wear Parts Topics within these sections include metallurgy options , liner profiles available , application examples , case studies , wear part codes etc. I hope this Guide provides an invaluable source of information that will assist you in selling Finlay

Learn More

Crusher Wear Parts Selection Guide For Cones, Jaws, Impactors

2021. 8. 8. · The most important factor in Cone Crusher liner selection is the feed. You should have a well-graded feed going into the crushing chamber. A well-graded feed is generally considered as 90-100% passing the closed-side feed opening. Some people look at 80% of the open side as well and select the smaller of the two;

Learn More

cone crusher liner selection | crusher bushing dealer in nepal

used cone crusher liner. Cone crusher liners need periodic replacement to protect cone crusher and keep the output, so the better selection, the less cost and more profit.In this post, we will discuss from material selection,cavity selection and foundry selection.Cone Crusher - an overview | ScienceDirect Topics,The secondary

Learn More

Cone Crushers | McLanahan

When should I replace my Cone Crusher liner? If the liner is wearing evenly throughout the chamber, you should consider changing out the manganese when it has worn down to about 1" (2.5 cm) thick at the bottom. At about 3/4" to 5/8" (1.9 to 1.6 cm) thick, the manganese will crack, causing the backing material to begin to disintegrate.

Learn More

Cone Crusher - an overview | ScienceDirect Topics

The secondary crushers are designated as Standard cone crushers having stepped liners and tertiary Short Head cone crushers, which have smoother crushing faces and steeper cone angles of the breaking head. The approximate distance of the annular space at the discharge end designates the size of the cone crushers. A brief summary of the design characteristics is

Learn More

cone crusher liner selection | used rock crusher frame bushing

HP200™ cone crusher Outotec ® HP200™ cone crusher is the second smallest model in the well-known ® HP Series™ co. Crusher includes a lubrication tank, hydraulic cabinet, temperature gauge, oil pressure gauge, and used wear liners.1993 HP200 Cone Crusher Serial # China

Learn More

cone crusher liner selection - Wear Parts For Industry - Qiming Casting

Cone crusher liner selection, which is very important selection for user. Cone crusher liners need periodic replacement to protect cone crusher and keep the output, so the better selection, the less cost and more profit.In this post, we will discuss from material selection,cavity selection and foundry selection. 1.Material selection:

Learn More

cone crusher liner selection cs 7 ft cone crusher spare main shaft

Name Provider Purpose Expiry Type; _ok: Olark: Identifies the visitor across devices and visits, in order to optimize the chat-box function on the website.

Learn More

Cone crusher parts - Wear Parts For Industry | Qiming Casting

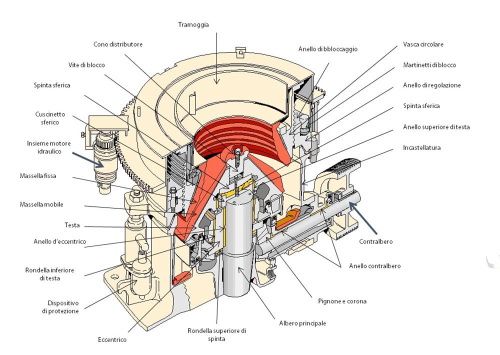

Cone crusher wear parts include cone liners, bowl liners; Cone crusher spare parts include: cone crusher spider cap, top shell, and spider, cone crusher main shaft, head center, cone crusher step bearing, cone crusher dust seal, cone crusher eccentric bushings, cone crusher bottom shell and so on.

Learn More

Prolonging Cone Crusher Liner Life - Agg-Net

Depending on the stone being crushed, the percentage of manganese in the liners can vary from around 12% to 23%. Care has to be taken during selection, as

Learn More

Selecting A Long Life Crusher Liner - Quarry Magazine

Before selecting a crushing chamber, you should take a sieve analysis of the feed to find out if you have a well-graded feed. Look first at the

Learn More

Considerations When Selecting a New Crusher Liner - Cast Steel

2021. 6. 7. · A crusher is a machine designed to reduce large rocks into smaller rocks and gravel. A wide range of cone crusher liners are available to accommodate coarse and fine feeds, but which you choose depends on several factors. The most crucial element in cone crusher liner selection is the feed. You should have a well-graded feed going into the crushing chamber.

Learn More

Research on the Wear Behavior of the Fixed Cone Liner of a

The UG model and discrete element Yade model of the cone crusher are (19−21) The soft sphere model is selected based on the DEM,

Learn More