clinker cooler operation

Clinker Coolers – Everything for cement

20/08/2022 · Clinker Coolers August 20, 2022 In cement manufacturing, formation of clinker nodules occurs at the entrance to the hottest part of the kiln with a material temperature of around 1280°C. The clinker is preferably in the form of 10-mm to 25-mm size nodules that exit from the front end of the kiln into the cooler.

Learn More

Vibrations on Clinker Cooler Structure due to operation of Breaker

Vibration were recorded at Cooler Structure Building. Observations and recommendations are placed below: 1. Vibration levels on all the machines are well within limit. 2. All column vibrations are low whereas floor vibrations at 5 m level are below 30 microns and at 15 m level are below 40 microns. 3. Vibrations on steel structure is 75 microns.

Learn More

Thermodynamics and Parametric Study of the Grate

operating parameters in a grate clinNer cooler operations. Process Description of Grate Clinker Cooler (GCC). In the cement industry,

Learn More

Clinker Cooler - A Vital Unit in Cement Pyro Section - Techcem

Typically, the clinker coolers release large amounts of heated air at 250 to 340° C which can effectively be used in WHRS system. The steam turbine based waste heat recovery boilers (WHRB) are placed between the cooler and the de-dusting system. Depending on situations / requirements, various configurations are considered which are shown below.

Learn More

Clinker Cooler, Cement Cooler, Grate Cooler | Clinker Production

The cooler will make a sufficient heat exchange between the clinker (1000-1200℃) from the rotary kiln and air by cooler rotating, so that the material can be cooled to (below 200℃), and improve the clinker quality and grindability, our clinker cooler with the features of simple structure, high transport rate, easy operation and maintenance.

Learn More

Clinker Cooler, Cement Cooler, Grate Cooler | Clinker

The cooler will make a sufficient heat exchange between the clinker (1000-1200℃) from the rotary kiln and air by cooler rotating, so that the material can be cooled to (below 200℃), and

Learn More

On-site services for clinker coolers

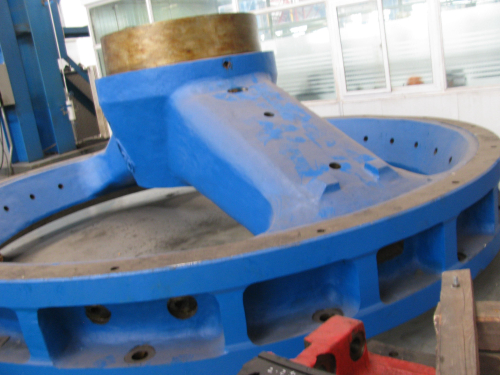

The clinker-cooler is working constantly for your plant and preventative maintenance is vital to keep availability high. You need to avoid excessive we components, and have the right spare parts on hand for planned maintenance. After a complete cooler overhaul, to ensure the best possible start to your operations, we'll stay on-site

Learn More

PDF) Optimizing the Control System of Clinker Cooling: Process

19/08/ · Abstract and Figures. This paper aims to present efficient efforts to optimize the proportional-integral-differential (PID) controller of clinker cooling in grate coolers, which have a fixed grate

Learn More

Cement Cooler - Clinker Cooler | Types Of Clinker Cooler AGICO

Clinker enters from one end and is lifted and scattered by flights. At the same time, the cold air enters from the other end and contacts with the clinker countercurrent for heat exchange. The rotary cooler is generally arranged under the rotary kiln, with a diameter of 2-5m and a length of 20-50m. Grate cooler Grate cooler is a quench type cooler.

Learn More

Clinker Cooler Optimization

Clinker Cooler Optimization” aims to improve cooler heat recovery efficiency of the existing clinker cooler with optimizing cooling air volume/pressure, thickness of clinker bed and grate speed. Big modifications of the existing clinker cooler are not necessary. Other effects. Clinker output, clinker quality and heat consumption are improved.

Learn More

CLINKER COOLER SECTION - Kiln Operation

In document Kiln Operation (Page 77-83) COOLER. FUNCTION. a) The main function of the cooler is to recuperate the heat contained in the clinker coming from the kiln as heat recovery from

Learn More

Evaluating the thermodynamic efficiency of the cement grate

When compared to actual operating data, the total clinker cooling air decreases by 5%, of operating parameters in a grate clinker cooler operations.

Learn More

Clinker Coolers - Everything for cement

Clinker Coolers August 20, 2022 In cement manufacturing, formation of clinker nodules occurs at the entrance to the hottest part of the kiln with a material temperature of around 1280°C. The clinker is preferably in the form of 10-mm to 25-mm size nodules that exit from the front end of the kiln into the cooler.

Learn More

Juan Ortega - Cement Specialist / INfluenCement™ on

Red River is a phenomenon in grate cooler caused by poor cooling of hot clinker; it is often a narrow red-hot stream of fine clinker with a higher Juan Ortega - Cement Specialist / INfluenCement™ on : #influencement #cement #technology #innovation #networking #synergy #posts

Learn More

Latest Developments in High Efficency Clinker Cooling

Clinker Cooler Drive - Safeguard operation Failure mode: Modern ETA Cooler Traditional Grate cooler Failure of one pump Bypass is opened, clinker production continues Standby pump must be activated Failure of one lane drive Production continues at almost 100% Capacity

Learn More

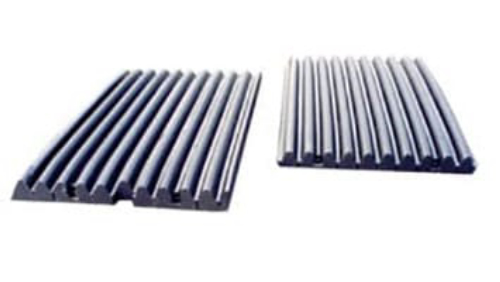

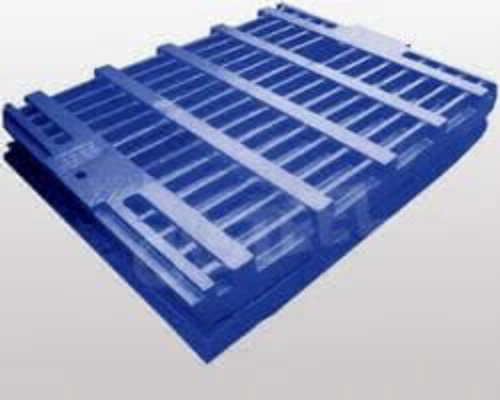

polytrack - thyssenkrupp Polysius

Operation principle of the clinker cooler Stationary, low-wear aeration grate. The air is distributed to the material bed via static aeration units located between the transport tracks. Since the aeration plates do not move and the conveying elements are sealed with a continuous sealing from the adjacent aeration floor, there is virtually no

Learn More

performance evaluation of a grate cooler in a cement ... - IJSEAS

cooler operation parameters such as clinker temperature, cooler efficiency and heat losses. These parameters have to be monitored

Learn More

eCFR :: 40 CFR 63.1343 -- What standards apply to my kilns, clinker

New clinker cooler: Normal operation: Major or area source: PM 0.02: lb/ton clinker: NA. 10. New clinker cooler: Startup and shutdown: Major or area source: Work practices (63.1348(b)(9)) NA: NA. 11. Existing or new raw material dryer: Normal operation: Major or area source: THC 3 4 24: ppmvd: NA. 12. Existing or new raw material dryer

Learn More

Evaluating the thermodynamic efficiency of the cement grate clinker

The operating functions of the grate clinker cooler include: on the inclined fixed grid plate, the clinker in the rotary kiln is dropped and the moving grate plate moved the clinker forward with the aid of the moving bar.

Learn More

Clinker Cooler - Cement Cooler | AGICO Cooler In Cement Plant

Clinker cooler transfers heat from clinker to combustion air to improve the heat exchange process and reduce fuel consumption to some extent. obtain clinker at an appropriate temperature for further grinding, storage and conveying. The cement clinker after sintering is not the final cement product sold in the market.

Learn More

inside parts of clinker cooler encyclopedia

Clinker cement Wikipedia. Cement kilns are used for the pyroprocessing stage of manufacture of Portland and other types In the cooler the air is heated by the cooling clinker so that it may be 400 to 800 °C If part of the fuel necessary to burn the rawmix is burned outside the kiln the output of the system can be increased for a given kiln sizeClinker At the outlet of the kiln the clinker

Learn More