clinker cooler

Clinker Grate Cooler for Cement Plant

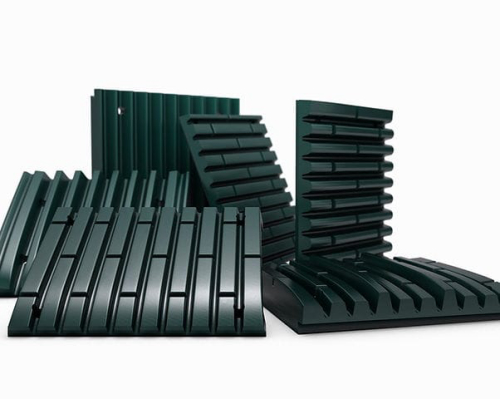

Uses: The grate cooler is an important main equipment in the clinker burning system of the cement plant. Its main function is to cool and transport the cement clinker. At the same time, it provides hot air for the rotary kiln and the decomposition furnace, which is the heat recovery of the firing system. The main equipment.

Learn More

Cement Cooler - Clinker Cooler | Types Of Clinker Cooler AGICO

Clinker enters from one end and is lifted and scattered by flights. At the same time, the cold air enters from the other end and contacts with the clinker countercurrent for heat exchange. The rotary cooler is generally arranged under the rotary kiln, with a diameter of 2-5m and a length of 20-50m. Grate cooler Grate cooler is a quench type cooler.

Learn More

Clinker cooler - level and pressure measurement | VEGA

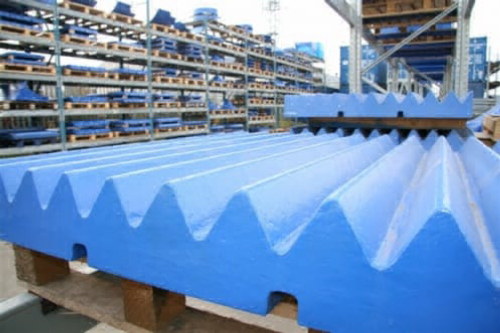

To produce cement, the raw meal is burned to clinker in a long rotary kiln. After leaving the rotary kiln, the clinker has a temperature of up to +1300 °C and must be cooled down to a temperature of about +200 °C for further storage. To achieve this, the clinker bed is cooled with a continuous stream of air.

Learn More

Clinker coolers | SKF

Clinker coolers Deal with the equipment demands of heat, dust and high loads at low speed. And increase reliability and availability while keeping maintenance costs down. Stay up and running

Learn More

polytrack - thyssenkrupp Polysius

The cooler is a vital component of the clinker production line and its performance is interdependent with that of the kiln. Our experts have extensive

Learn More

PDF ETA Cooler - Claudius PetersPDF

Clinker coolers must take clinker from ca. 1400°C to ca. 100°C, with maximum possible heat going back to the kiln. Because kiln rotation separates fine and coarse grains across the kiln and because each require different air pressures for cooling, traditional grate coolers produce 'red rivers' of hot, fluidised clinker that flow to the

Learn More

Grate Cooler in Cement Plant

AGICO supplies grate coolers for cement clinker production. The clinker coolers we offer are the most advanced reciprocating grate coolers, which are widely

Learn More

clinker cooler balance - [PDF Document

As shown in Fig. 1, high temperature clinker get into grate cooler from rotary kiln. Clinker layermoves slowly on grate bed. Cooling air blows into the clinker layer vertically from the bottom ofthe clinker, permeates and diuses in the clinker to cool the red-hot clinker. Cooling air becomeshot air after exchanging heat energy with clinker.

Learn More

Clinker Grate Cooler for Cement Plant - Rotary Kiln

Uses: The grate cooler is an important main equipment in the clinker burning system of the cement plant. Its main function is to cool and transport the cement

Learn More

Martin Engineering

Rethinking Clinker Cooler Buildup. The Sustainability Commitments 2030 program aims to make HeidelbergCement an industry leader in workplace safety. Lehigh-Hanson's expectations for a proposed solution required the system to: · Be highly reliable and accessible. · Eliminate material buildup within the cooler.

Learn More

Coolers | Costco

MaxCold 5 Day Performance Cooler, 144 Can Capacity; Quick Access Lid with 4 Self-Draining Cup Holders; Oversized Wheels for All Terrain Mobility; Oversized Engineering Grade Hinges with Stay-Open Detent; Cool Riser Technology™ for Improved Cooling Performance; Rated 4.1 out of 5 stars based on 57 reviews.

Learn More

Clinker cooler - All industrial manufacturers - DirectIndustry

of ownership Reduce your clinker cooling costs with the Cross-Bar® Cooler The Cross-Bar Cooler is the latest evolution in clinker cooling

Learn More

How Does Clinker Cooler Reduce Cement Production Energy Consumption

Cooling fans of a grate cooler The main power consumption of a clinker cooler is its cooling fans. It usually takes 1.9-2.3 m 3 under standard conditions to cool 1 kg clinker from 1400 ℃ to 65 ℃, and the power consumption of the whole system is about 7 kWh.

Learn More

Grate Cooler | Clinker Cooler, Cement Cooler | Cement Plant Equipment

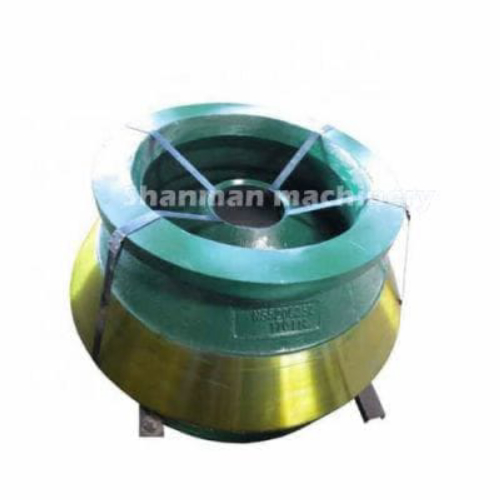

Cooling clinker The clinker temperature is an important indicator of the grate cooler performance, which reflects the cooling efficiency of the grate cooler, and also creates conditions for the conveyer, storage, and cement grinding of clinker in subsequent processes.

Learn More

Virtual-Lab of a Cement Clinker Cooler for Operator Training

A virtual-lab of a clinker grate cooler, intended for training of cement plant operators, has been developed. The grate cooler model has been derived from

Learn More

Clinker cooling - INFINITY FOR CEMENT EQUIPMENT

The speed of clinker cooling influences the ratio between the content of crystalline and liquid phases in the clinker. During slow cooling, crystals of almost

Learn More

Clinker Cooler - AGICO Cement Plant

The clinker cooler, also known as grate cooler or cement cooler, it is a necessary equipment of cement clinker production. The clinker cooler is mainly used

Learn More

Clinker Coolers - SolidsWiki

Clinker Coolers The purpose of a Clinker Cooler is to cool the clinker. From an engineering viewpoint, cooling is necessary to prevent damage to clinker handling equipment such as conveyors.From both a process and chemical viewpoint, it is beneficial to minimise clinker temperature as it enters the clinker mill.

Learn More

7-Eleven hiring Cooler Stocker in Hillsboro, Oregon, United States

Perform cashier duties (ring sales and maintain cash control) Perform all regular cleaning activities, and other tasks included in your job assignments. Forecast, order and stock merchandise (with

Learn More

Clinker cooler - Lechler

Injecting water into the clinker cooler provides a remedy here. The cooling of the gas also causes the gas volume to reduce and protects

Learn More

CLINKER COOLER - Deha Tech

Clinker cooling is one of the important processes in cement production. Improving the cooling effect also can reduce the clinker temperature, recover the waste

Learn More