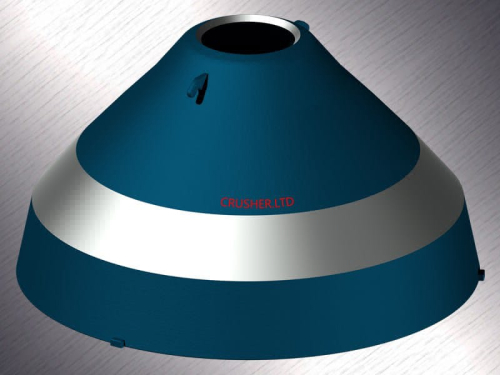

cone crusher lubrication system

HP300 SOCKET LINER | mill lubrication system

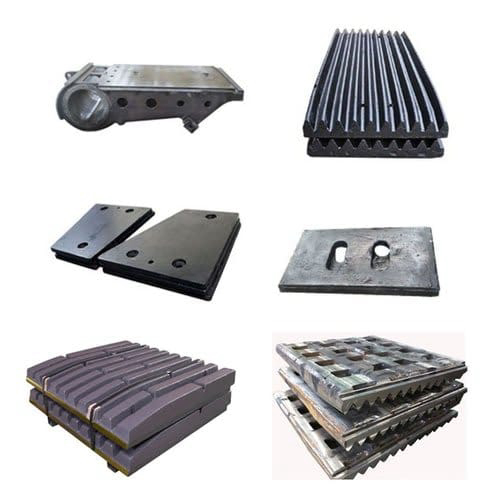

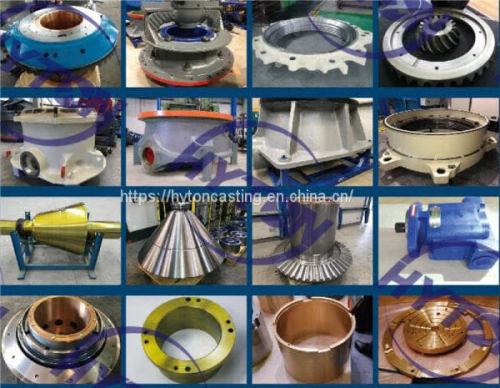

HP300 cone crusher parts database and search tooling. Large bronze bearing Cone crusher socket liner Cone crusher spider bushing Crusher shaft High Chromium parts High manganese steel Jaw crusher plate side plate Other bronze parts Other steel parts Ball mill HP100, HP200, HP300, HP400, HP500, HP700, HP800. 42-65,50-65,54-75,60-89,60

Learn More

Cone Crusher Pyb 900 Lubrication System

Cone Crusher-Jiangsu Zhongbo Machinery – Crusher and ball . Cone Crusher is suitable for crushing alI kinds of ores and rocks above medium hardness.It has the features of reliable

Learn More

Download Ebook Service Manual Gp Series Crusher

GP CONE CRUSHERS INSTRUC-TION MANUAL, BEFORE STARTING, PRES-SURIZED DUST SEALING, STORAGE, MAIN-TENANCE, SCHEDULED MAINTENANCE. Service Manual HP® Se-ries Cone Crusher Lubrication Supplement. 8:02 pm 29 Jul 2019. GP Cone Crusher Instruc-tion Manual MM0293378 ® GP Series™ cone crushers are

Learn More

Cone Crushers - Parker Plant

Cone Crusher & Hydraulic Control System Parker 900, 1200 or 1350 cone fitted with any one of seven interchangeable crushing cavities. Power Unit Either Electric or diesel hydraulic Caterpillar engine or similar if stated otherwise Control Functions Setting adjustment, even under full crushing load. Hydraulic overload tramp iron protection.

Learn More

cone crusher manual | Henan Deya Machinery Co., Ltd

31/03/2022 · This is an installation and use manual for cone crusher operators. For experienced personnel, reading this manual will make you more familiar with the machine. The instructions and diagrams in this manual will help you to properly check, start and operate the crusher and its auxiliary equipment.

Learn More

How to protect cone crusher lubrication system in Winter season?

Cone crusher usually works in factory, if you use for heat preservation measures, we should install corresponding electric heating devices the fuel tank so as to improve lubricating oil temperature before starting and ensure the smooth work in lubrication system . When cone crusher works about 1200-2000 hours, lubricating oil reaches the use of time and it should be replaced new lubricating oil, At the meanwhile , we clean oil tank and oil pipe .

Learn More

NEW lubrication system

Manufactured in the United Kingdom. CMS Cepcor lubrication system. Compatible with all 3' cone crushers. Airblast cooler. Gear pump. Modern filtration

Learn More

Lubricating crushing machines in quarries - Rock to Road

The actual crusher can be in the form of a cone, gyratory, impact, jaw, etc. For crusher systems that use oil lubrication for example, contamination of

Learn More

CJC Application Study - Cone Crusher - Lubrication System

The operation test of the CJC Fine. Filter in crusher #2 showed, after 6 hours of filtration an ISO cleanliness class 15/12/9. At the same time.

Learn More

HP400 | Crushers Plus

HP400 cone crusher. Manganese steel crushing members. Hydraulic bowl clamping and adjustment. Hydraulic clearing of crushing chamber. Automatic tramp iron release, bronze bearings. Lubrication system (consisting of independent pump, oil pressure switch, oil temperature switch, oil tank with strainer, oil level gauge and two thermometers, and oil filter), oil cooler (air-radiator or water type)

Learn More

How to Choose the Lubricating Oil of Hydraulic Cone Crusher?

09/02/2022 · For the components of the cone crusher, parts that work under heavy loads require a more viscous lubricant. For example, when the bearing pressure is large, the oil is pressed

Learn More

Common Senses on Lubrication System of

When the lubricating system of cone crusher is not working, the oil level in oil receiver should reach the upper limit.

Learn More

Simmons Cone Crusher Lubrication System-HN Mining Machinery Manufacturer

Category cone crushers product description 1 one 5 standard cone crusher , 300 h.p. electric motor, v-belt drive with guard, manual adjustment, standard oil lubrication system with oil tank, 30 i-beam steel support structure with wrap around catwalk platform on four sides, date of mfr. 1954 sn 5299.

Learn More

Cone Crusher Lube Systems | Crusher Mills, Cone Crusher, Jaw Crushers

cone crusher lubrication system flow - Crusher South Africa Lubrication System for simons Cone Crusher. simons cone crusher is a common crusher which is widely used in mining industry. It adopts light oil lubrication system.

Learn More

HP Series Cone Crusher Lubrication Supplement

Separate instruction manual supplements provide detailed instructions for the lubrication system, hydraulics and crusher drive in addition to the main Cone

Learn More

Cone Crusher Lubrication System

The cone crusher is composed of frame, transmission, adjustment device, hydraulic system and lubrication system. The lubrication system is an indispensable device for each crushing machine to ensure the good lubrication of the equipment and provide the crushing work for the cone crusher. condition. How the lubrication system works. The pressure

Learn More

Lubrication-system Cone-crusher 1200

cone crusher can be widely used overload hydraulic cavity cleaning system and lubrication system with refrigerants fully ensure the safety 1200(4') Fine CS Series Cone Crusher- Heavy Industry (Shanghai)

Learn More

cone crusher lubrication station

Five steps to optimize crusher''s lubrication system. Jul 30 1 Monitoring of lube oil temperature A lot can be learned about a cone crusher by simply

Learn More

Cone crusher equipment lubrication system work common sense

1.Only in the lubrication system operation, and the lubricating oil back to the tank before they can start cone crusher; 2.Whether it is summer or winter, should run the cone crusher to make the lubricating oil temperature rise, oil return temperature must be 39 ℃ ~ 54 ℃; cooling system will keep the oil temperature in the safe operating range.

Learn More

Perfect Lubrication System Cone Crushing for Mine/Coal

Also cone crusher uses the compensating lubricating grease sealing, it can avoid lubrication oil being polluted by dust, so that all parts work reliably and have a long operating life. The safety insurance system of cone crusher uses several spring sets, so the matter and iron ore are down from the crushing cavity and do not damage the crusher, simply and reliably.

Learn More

CH895i Cone crusher — SRP

It lets you track and trace parts online to make maintenance planning simpler. The CH895i comes with the new generation Automation and Connectivity System (ACS) as standard. The system continuously monitors and optimizes crusher performance and controls the complete lubrication system, increasing uptime and reliability.

Learn More