jaw crusher throw

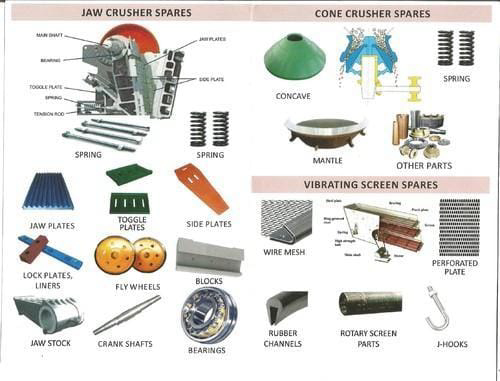

Diagram Jaw Crusher | Crusher Mills, Cone Crusher, Jaw Crushers

Jaw crusher,Ball mills,Cone crusher,Sand maker,Rotary kiln Gulin Machinery provides you Stone Crusher, Jaw Crusher, Vibrating Screen,Rotary kiln, Ball mills etc. diagram jaw crusher system conveyor – Crushing Plant. Engineering Products, Secondary Jaw Crusher, Offering Conveyor Systems, Hydraulic Conveyor Systems, Mechanical Conveyor

Learn More

Blake Crushers - SolidsWiki

Blake Crushers are Jaw Crushers with a movable jaw pivoted at the top, giving greatest movement to the smallest lumps. The throw of Blake

Learn More

C96 JAW, FIXED SUPER GRIP 1P | mill replacement part

Able to sling three regulated .50 caliber shots per fill, the Hammer utilizes Umarex's patent-pending Lightspeed™ valve created specifically to deliver jaw-dropping power. Crafted to throw 550 grain, .50 caliber slugs downrange at 760fps for an unheard of 700 FPE, and a 250gr slug at 1,000 fps—the Hammer has more than enough power to

Learn More

fracture toughness based models for the prediction of power

The throw of a jaw crusher is dependent upon the type of crushing required. For coarse crushing a long stroke is used and for fine crushing a short stroke

Learn More

Gyratory Crushers - Mineral Processing & Metallurgy

Jaw crushers must be belt-driven. An efficient substitute for the flat belt in all cases is the Texrope drive, which consists of a number of V-shaped endless rubber belts running on special grooved pulleys. The grip of these belts is so great that the distance between the pulley centres can be reduced to about 30% of that required for a flat belt.

Learn More

Jaw Crushers | McLanahan

The Jaw Crusher was first introduced by Eli Whitney Blake in 1858 as a double-toggle Jaw Crusher. Introduced in 1906, McLanahan’s Universal Jaw Crusher was one of the first modern era overhead eccentric Jaw Crushers. On the overhead eccentric style Jaw Crusher, the moving swing jaw is suspended on the eccentric shaft with heavy-duty double

Learn More

Jaw Crusher Explained - saVRee

For example, a 32 x 54 sized jaw crusher will measure 32 inches from the movable to stationary jaw (when measured at the top i.e. the opening), and each jaw will have a 54-inch width. If a jaw crusher is rated by jaw plate size, a suitable rating maybe 600 x 400, which indicates a 600 mm by 400 mm jaw plate dimension.

Learn More

Jaw Crushers - Astec

Available in a variety of sizes and configurations, the Hydra-Jaw® crusher, Pioneer® jaw crusher and Iron Giant jaw crushers deliver high-capacity crushing and reliable performance for increased operational productivity and profitability. Our diverse line of industry-leading jaw crushers offers producers the latest in jaw crushing technology

Learn More

T HE advent of curved jaw crusher wearing plates - RocketCDN

the addition of an eccentric throw factor, is appli- cable to standard types of single-toggle or overhead eccentric jaw crushers as far as maximum capacity.

Learn More

jaw crusher throw

jaw crusher throw. small jaw crusher. The 911MPEJAC23is aSmallJaw Crusher of 2.25 X 3manufactured to easily crush any rock from 2 (50mm) down to a D50 of 700 micron (28 Mesh) which also correspond to acrushed discharge P80 size of 80% passing 1400 microns or 14 mesh. The discharge opening (closed-side-setting) of this 55mm X 75mm big-small

Learn More

Crushers - an overview | ScienceDirect Topics

Jaw crushers are mainly used as primary crushers to produce material that can be transported by belt conveyors to the next crushing stages. The crushing process takes place between a fixed jaw and a moving jaw. Because the jaw is pivoted at the top, the throw is greatest at the discharge, preventing chocking. Figure 10.1. Crushing machine [1].

Learn More

EX Cone Crusher|Crushing/Grinding

We have supplied more than two thousand cone crushers for the last 50 years.These EXCONE are under operation at THROW(mm), Capacity(mt/h) at Large ECC.

Learn More

Jaw Crusher - an overview | ScienceDirect Topics

For a jaw crusher the thickness of the largest particle should not normally exceed 80–85% of the gape. Assuming in this case the largest particle to be crushed is 85% of the gape, then the

Learn More

Capacities and performance characteristics of jaw crushers

The study showed that industrial jaw crushers are generally operated below capacity. parameter related to throw of the crusher.

Learn More

Control Of Closed Side Setting And Throw Of Jaw Crushers

Mobile Jaw Crusher Closed Side Setting css Range. Measuring the closed side setting css or open side setting oss is usually confusing as many methods are employed without understanding consequences css is the smallest discharge opening dimension on the jaw oss is the largest discharge opening dimension on the jaw it is equal to the css plus the throw of the swing stock the dimension on

Learn More

Gyratory Crusher Explained - saVRee

Gyratory Crushers; Jaw Crushers; Cone Crushers Crushing action is produced by the oscillation or 'throw' (opening & closing) of the gap between the

Learn More

Mobile Jaw Crusher Closed Side Setting (CSS

It is equal to the CSS plus the throw of the swing stock. The dimension on the discharge end of the jaw liners are measured from Peak to Root. To measure the

Learn More

Crusher Aggregate Equipment For Sale in HILLSBORO, OREGON - 28 Listings

Browse a wide selection of new and used Crusher Aggregate Equipment for sale near you at MachineryTrader.com. Find Crusher Aggregate Equipment from CEDARAPIDS, KPI-JCI, and , and more, for sale in HILLSBORO, OREGON

Learn More

Crusher Aggregate Equipment For Sale in HILLSBORO, OREGON - 2

Browse a wide selection of new and used Crusher Aggregate Equipment for sale near you at MachineryTrader.com. Top models for sale in HILLSBORO, OREGON include C3R and C4

Learn More

How does a Rock Crusher Work - Jaw Crusher - 911Metallurgist

A jaw crusher is recommended for tough, abrasive, high compressive strength materials. Special machines have been designed for ores having compressive strength as high as 80,000 lbs per sq in. All-steel sectionalized frame. End members are box section. Deep side members of welded steel plate.

Learn More

Jaw Crusher | Crushing Plant | Hard Rock Mining Equipment | DOVE

DOVE Jaw Crushers are ideal rock crusher machines, highly efficient and economical for handling Primary and Secondary stone crushing applications of various ores and bulk materials with compressive strength below 320 MPa.DOVE Crushers are supplied in Stationary complex plant configuration, or in Portable and Mobile configuration.. Designed with optimum cavities and

Learn More