cone crusher maintenance

How To Get The Most Out Of Your Cone Crusher

3. How difficult will maintenance be? Unfortunately not all cone crushers are built to last. If you are looking for a piece of equipment to get

Learn More

Cone Crusher Maintenance - Precision Casting

Cone Crusher Maintenance. Doing frequently set up maintenance on cone crusher is the most critical action in maintaining day-to-day integrity and maximum product outcome. Let it be known that even executing minor cleanup as well as evaluations around and also on cone crushers daily can produce raised life span. Let us show some tips for cone

Learn More

Regular crusher maintenance integral to reliability, performance and

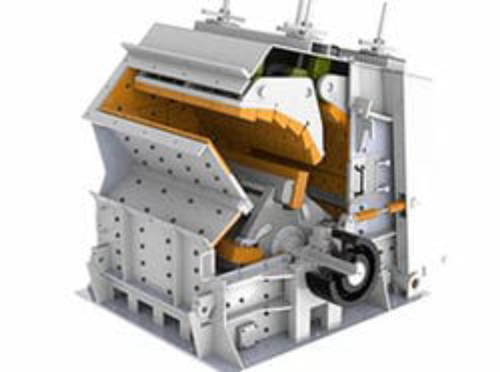

Performing regular maintenance on crushers is integral to the reliability, performance and output they achieve. Prevention is better than cure; by carrying out regular inspections operators will ensure their crusher runs for a longer period of time with minimal unscheduled downtime. Cone crushers have evolved from the earlier models

Learn More

Cone Crusher Maintenance Manufacture and Cone Crusher Maintenance

we are able to supply top quality items, aggressive price and greatest buyer assistance. Our destination is ""You come here with difficulty and we offer you a smile to take away"" for Cone Crusher Maintenance, Cone Crusher Mantle, Cone Crusher Machine, We believe in quality and customer satisfaction achieved by a team of highly dedicated individuals.

Learn More

Cone crusher maintenance critical to optimum output - Quarry

If your crusher is equipped with an external-mounted oil pump, the following must be carried out: • Lubricate the oil pump bearings every 500 hours. • Check reservoir oil level daily and change oil every 600 hours of operation. • Perform a weekly inspection of the oil pump shaft seal.

Learn More

Cone crusher parts - Outotec

Reliable cone crusher wear and spare parts enable stable production without unexpected downtime. We have a wide cone crusher spare parts offering for Outotec, ®, and ™ models, as well as many crushers made by other manufacturers. The parts are available as standard or tailor-made according to your application requirements.

Learn More

4 Types of Stone Crushers' Maintenance and Efficient Improvement

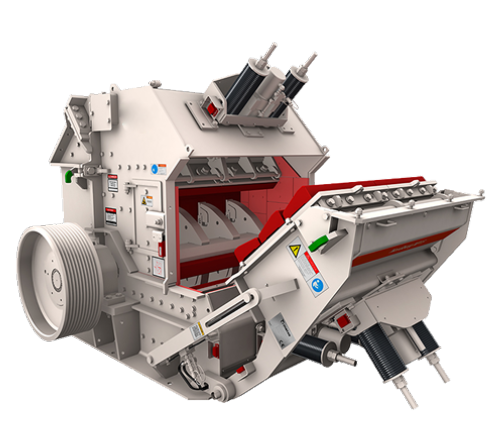

The regular maintenance and repair include adjustment of the gap between the rotor of the impact crusher and the impact lining plate, replacement of wearing parts, regular inspection of the hammer, lining plate, bearing temperature, etc. Replace badly wearing parts in time. Regularly inspect temperature of the rotor, motor and bearing, etc.

Learn More

Maintenance Of Cone Crushers | Crusher Mills, Cone Crusher, Jaw Crushers

Cone crusher operation and maintenance, cone crusher supplier is a world famous manufacturer of crushing plants in China. cone crusher operation and maintenance is very easy and convenient.

Learn More

Industrial Crusher maintenance and rebuilds

We have expertise in cone crushers, hammer or impact mills, and jaw style. The shop is equipped with large cranes for handling the heavy loads, large welding

Learn More

Maintenance of Cone Crusher Hydraulic System

2022/5/30 · Cone crusher is widely used in mine production due to its high crushing efficiency, low maintenance cost and large output capacity. Cone crushers are divided into spring cone crushers and hydraulic cone crushers, both of which can be used for the production of medium and fine crushing of high-hardness materials.

Learn More

Cone Crusher Maintenance Manual | Crusher Mills, Cone Crusher, Jaw Crushers

Rock Crusher Maintenance; How to maintain cone crusher; Jaw crusher for bulky waste and like matter; Cone Crushers - QMM - Quarry and Mining Manufacture Pty Ltd. If you are looking to purchase an honest, value for money cone crusher then look no further. A comprehensive service manual is also provided.

Learn More

The Maintenance of Cone Crusher

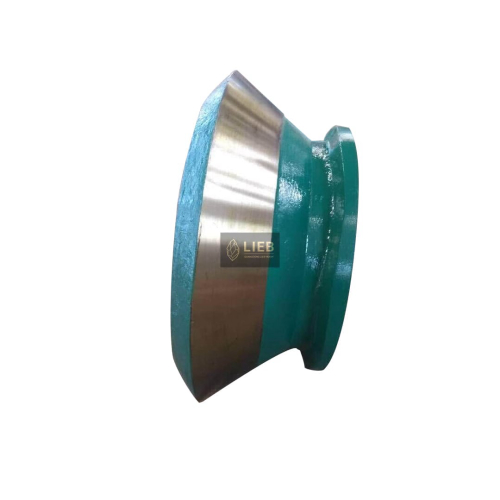

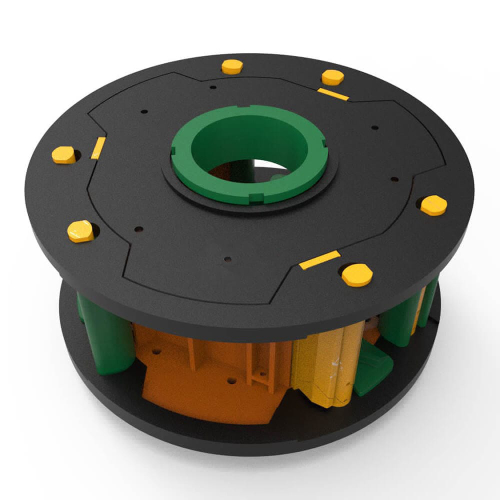

Therefore, many customers pay more attention to the maintenance of cone crusher. Here are some suggestions to maintain it, hope it is useful. 1. The maintenance of bearings. We all know the bearings plays the role of the aorta, and operates under the full load when the machine is running. So let the bearings with good lubrication has a direct

Learn More

Cone Crusher Maintenance - Qiming Machinery

Doing frequently set up maintenance on cone crusher is the most critical action in maintaining day-to-day integrity and maximum product outcome. Let it be known that even executing minor cleanup as well as evaluations around and also on cone crushers daily can produce raised life span. Let us show some tips for cone crusher maintenance.

Learn More

Cone Crusher - an overview | ScienceDirect Topics

Maintenance of the wear components in both gyratory and cone crushers is one of the major operating costs. Wear monitoring is possible using a Faro Arm (Figure 6.10), which is a portable coordinate measurement machine.Ultrasonic profiling is also used. A more

Learn More

Cone Crusher Maintenance - Mineral Processing & Metallurgy

When the crushing pressure returns to normal, the pressure in the accumulator resets the crushing head to its original position. The Automatic Reset functions separately from the Speed-Set control. Its operation is entirely automatic. Only non-explosive gases, such as nitrogen, should be used for filling the Automatic Reset.

Learn More

Cone Crusher Maintenance Guide | Crusher Mills, Cone

cone crusher maintenance manual – grinding plant Pdf. CS cone crusher manual pdf crushing plant – all electric plant simons 4 std cone crusher w 125-hp305 toy Jaw Crusher Repair and

Learn More

Good Quality Maintenance Manual Pdf Eccentric Bushing

CS-series spring cone crusher is applied in gravel construction and artificial sand processing especially in crushing hard material such as basalt. it is not

Learn More

Cone crusher maintenance. - Free Online Library

8/1 · Keeping the cone crusher choke fed during operation maximizes the effectiveness of rock-on-rock crushing, maintains maximum manganese wear life, and ensures a quality product shape. A lack of feed causes inconstant loading of the machine, which affects the long-term life of all internal components.

Learn More

The basics of crusher maintenance ~ primary and secondary

Lubricate the crusher bearings daily per the OEM recommendations. New grease will keep dirt out of the bearings, extending the life of the

Learn More

Mining Industry Cone Crusher Maintenance

The China cone crusher is a machine used for rocks with compressive strength under 350MPa in mining, cement industry, easy maintenance, high Cone crushers features and benefits in ore crushing plants Cone crushers are the main equipment in mining industry, making the cone crusher machine maintenance easy and low costing.

Learn More

Cone Crusher Maintenance | Crusher Mills, Cone Crusher, Jaw Crushers

Cone crusher,CS cone crushers,Cone crusher manufacturer This series of cone crushers are used for crushing ores and rocks, and the advantages Easy to maintain, reduce the downtime and maintenance costs. 4. Stable running Cone Crushers - AIR POWER S.A. - VERDU Y CIA. Our cone crushers have a wide field of use.

Learn More