mantle crusher

Cone Crusher Parts – ywcrusher.com

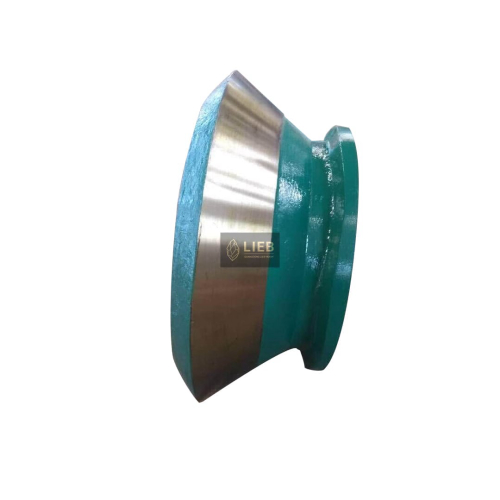

Cone Crusher Parts. 더스트실링. DUST SEAL RING 디스트리뷰터. DISTRIBUTOR 록킹칼라. LOCKING COLLAR 록포스트. Lock Post 립라이너. RIB LINER 맨틀. MANTLE 맨틀

Learn More

Fireplace Wood Mantle - in Augusta, GA - Shoppok

Find Fireplace Wood Mantle in Augusta, GA. New listings: Wood fireplace mantle (WESTMINSTER), Wood burning Fireplace mantle and accessories - $70 (Evans)

Learn More

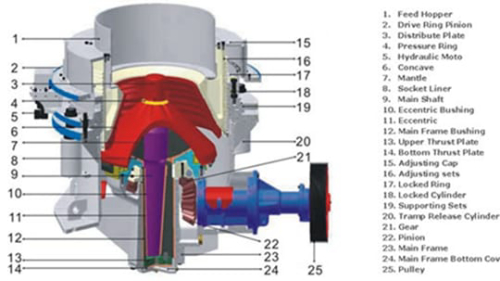

Cone Crusher Explained - saVRee

How Cone Crushers Work · crushed between the · mantle and · concaves; crushing takes place in the · crushing chamber. As the feed moves towards the drive end of the

Learn More

Primary gyratory crusher parts - Outotec

A crusher mantle or a set of concave segments with a longer wear life do not need to be replaced as often. You will need fewer per year but also have fewer

Learn More

Cone Crusher Mantle Latest Price, Manufacturers & Suppliers

High Manganese Steel Concave and Mantle at Best Price, For Crusher Machine. ₹ 1.6 Lakh/ Set Get Latest Price. Material: High Manganese Steel. Usage/Application: Crusher Machine. Color: Green. Brand: Compatible with OEM. Machine Type: Cone Crusher. Model Name/Number: GP11F GP200 GP11M HP300.

Learn More

Mantle Shaft For Crusher | Crusher Mills, Cone Crusher, Jaw

Bowl And Mantle For Cone Crusher: China Suppliers – 467941. Bowl And Mantle For Cone Crusher- Find detailed information about Crusher from Anxi Chang Xin Mining Machinery Parts

Learn More

HP Crusher Parts Mantle Filler Crushing Backing Compound Apply

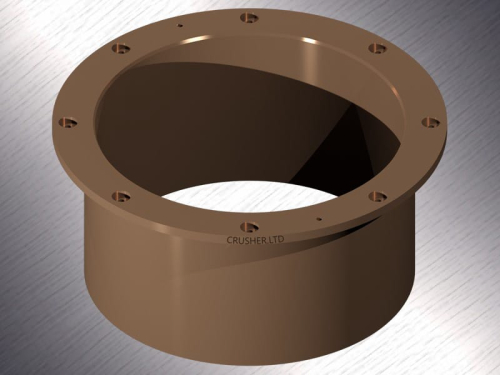

HP Crusher Parts Mantle Filler Crushing Backing Compound Apply To Metso. Hyton (Jiangsu) supply the one-stop service for almost all the spare and wear parts ,mainly include : Main Frame , Adjustment Ring Head Assy ,Bowl ,Drive Gear ,Counterweight assy ,Shaft ,Pitman ,Bronze Bushing ,Pump ,Tramp Release Cylinder ,Protection Bushing ,Bearing ,Seals ,Spring

Learn More

GP Series™ cone crushers - Outotec

The crusher automation enables adjusting the GP crushers from a distance, which reduces risks and improves the safety of the plant personnel. "S" range for secondary crushing stage The "S" range of ® GP Series™ is designed for demanding secondary crushing where the feed flow variates, and the feed size can be anything between extra

Learn More

HP Series™ cone crushers - Outotec

Crusher automation. Outotec IC70C™ is a crusher automation system that further improves the operation of your ® HP™ crusher. Using it can increase your production by more than 10%. With Outotec IC70C™ you can control maintenance, setting modifications, production follow-up and data extraction.

Learn More

Crusher Mantle Manufacture and Crusher Mantle Supplier in China

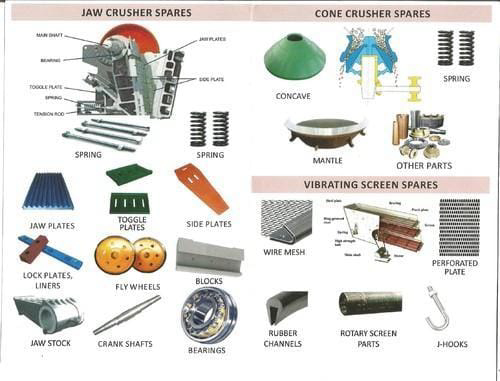

Crusher Mantle - manufacturer, factory, supplier from China. The Spring Cone Crusher. Cone Crushers are Suitable for all Crushing Needs. CONE CRUSHER MANTLE. upper thrust plate Cone Crusher Parts. Industrial Manganese Steel Jaw Crusher Spare Parts.

Learn More

Bowl Liner & Mantle | Wear Resistant Crusher Parts | GTEK

Cone crushers are widely used in the mining and aggregates industries to reduce the size of blasted rock by compressing the material between two manganese liners: mantle and bowl

Learn More

China Cone Crusher Mantle Factory and Suppliers

The crusher liner wear profile gauge is used to inspect worn mantle and concave. These examples are the same for all other cone crushers. launch

Learn More

product information mantel is designed to protect the cone crusher

mantle in a crusher plant you can buy various high quality bowl and mantle for cone crusher products from product information mantel is designed to protect the cone crusher. mantle in Chat Now; information of cone crusher cone crusher maintenance information. Product information of Cone Crusher Mantle : Mantel is designed to protect

Learn More

All crusher types for your reduction needs - Outotec

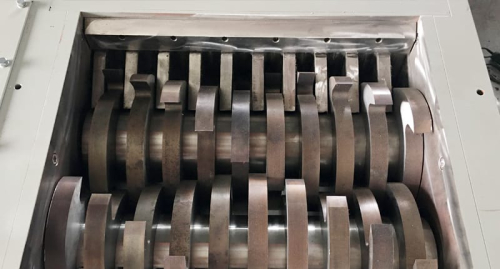

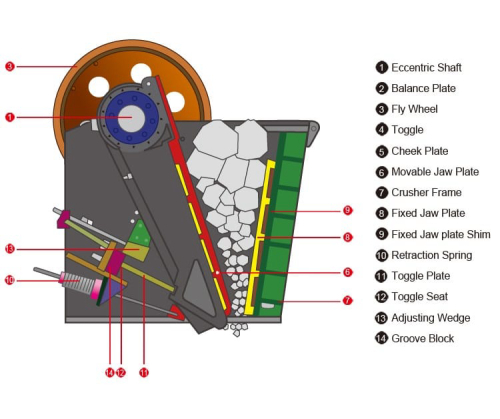

Compressive crushers that press the material until it breaks, and impact crushers using the principle of quick impacts to crush the material. Jaw crushers, gyratory crushers, and cone operate according to the compression principle. Impact crushers, in turn, utilize the impact principle. Jaw crushers . Jaw crushers are mainly used as primary

Learn More

12 tips to maximize cone crusher productivity - Outotec

11/02/ · Avoid trickle feeding the crusher. Try not to trickle feed a cone crusher. In addition to causing poor cone crusher productivity and product shape, trickle feeding has an impact on bearing alignment within said crusher. A crusher should be operated above 40% but below 100% rated horsepower in order to maximize cone crusher productivity and to

Learn More

Gyratory Crusher Explained - saVRee

Gyratory Crusher Mantle Travel Path. Crushed ore falls to the bottom shell assembly and is discharged into the crushed ore conveying system for further processing. The lower casing also houses a forced lubrication and hydraulic system, which is critical for the drive arrangement and hydro set mechanism.

Learn More

Cone Crusher Mantle - Hunan JY Casting

Heat the mantle to approximately 55° C (130°F). You should be able to touch the mantle but not hold your hand on it! Let mantle cool down before pouring the backing material. Turn the bolt with the wrench until fully tightened. Check the mark. The lock bolt should have turned approximately 25 mm (1 inch).

Learn More

Replacing the liner of a HP cone crusher - Outotec

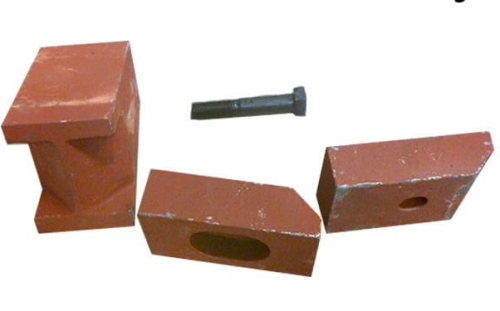

A) Mantle - also known as head liner. B) Cutting ring - the cutting ring is not reusable, so a new ring should be installed every time the mantle is replaced. D) Padding material - its purpose is to cushion (shock absorption), not to fasten the liners. Lubrication of the head/bowl is recommended to facilitate subsequent replacement.

Learn More

Gyratory Crusher - an overview | ScienceDirect Topics

The gyratory crusher shown in Figure 2.6 employs a crushing head, in the form of a truncated cone, mounted on a shaft, the upper end of which is held in a flexible bearing, whilst the lower end is driven eccentrically so as to describe a circle. The crushing action takes place round the whole of the cone and, since the maximum movement is at the bottom, the characteristics of the

Learn More

Cone Crusher Mantle - MGS Casting

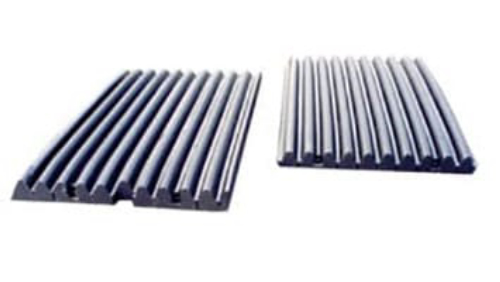

Cone crusher mantles are fitted with cone crusher adjustment ring with "U" seal. The mantles and concaves are the crushing parts. So they need exchange when they wear out. Cone Crusher Mantle Material Most of the mantles are cast by high manganese steel. it includes: Mn14Cr2 Mn18Cr2 Mn22Cr2 Mn14Cr2 + TIC insert Mn18Cr2 + TIC insert

Learn More

CSP Gyratory Crusher Wear Parts - Cast Steel Products

CSP manufactures concaves and mantles for Allis-Chalmers and Fuller/Traylor gyratory crushers. One-, Two- and Three-Piece Configurations are available.

Learn More