when is a small insert nose radius recommended?

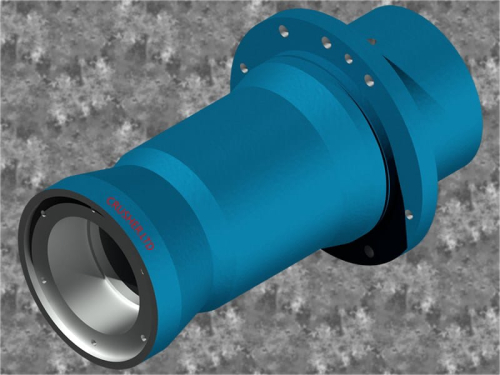

HP5 CNTRSHFT BUSHING | when is a small insert nose radius

ELKON on-site concrete batching plants make it possible to produce concrete economically even for small projects that require small quantity of concrete. As it can be commissioned within 1

Learn More

Turning Inserts Identification

Insert Shape; 2. Normal Clearance; 3. Tolerance Class; 4. Fixing and/or for Chip Breaker; 5. Insert Size; 6. Insert Thickness; 7.

Learn More

Insert Designations - CIMCO

Shape (CNMG-433)There are at least 18 different shapes of carbide inserts. The most commonly used are shown in Table 8.1 with their letter designation. The angle in this designation refers to the included nose angle at the cutting radius of the tool.

Learn More

Nose Radius in Cutting Tool - Its Function, Value, Advantage

Nose radius is the radius value of tiny rounding provided at the tip of the cutting tool, measured on reference plane. It prevents the tool tip from sudden

Learn More

How to choose correct turning insert – SIEESO

10/29 · Company, Technology. There are many parameters to consider when choosing turning insert. Carefully select insert geometry, insert grade, insert shape (nose angle),

Learn More

How to choose correct turning insert - SIEESO

Select a smaller nose radius if there is a tendency for vibration Turning insert geometry Turning geometries can be divided into three basic styles that are optimized for finishing, medium and roughing operations. The diagram shows the working area for each geometry, based on acceptable chip breaking, in relation to feed and depth of cut. Roughing

Learn More

How to choose correct turning insert - sandvik.coromant.com

As a general rule of thumb, choose a nose radius that is equal or smaller than the depth of cut. Positive or negative turning insert style A negative insert has an angle of 90° (0° clearance angle), while a positive insert has an angle of less than 90° (for example, 7° clearance angle).

Learn More

Nose Radius Selection and Surface Finish Application Guidelines for Conventional Inserts* TURNING INSERTS

If no available nose radius will produce the required finish, feed rate must be reduced. • Reverse the procedure to obtain surface finish from a given nose radius. *NOTE: See pages A20 - A23 for radius and surface finish specifications using wiper-style inserts. 1

Learn More

Internal turning - Coromant

An entering angle close to 90° (0° lead angle) and never less than 75° (15° lead angle) is recommended. Tool holder If there is a shoulder to machine in the component, choose a tool with 91-95° entering angle (-1 to -5° lead angle). It is recommended to use a triangular or a D-style (55°) insert.

Learn More

PDF) Effects of Insert Nose Radius and Processing ... - ResearchGate

machining at 0.4 mm insert nose radius to 1.2 mm insert nose radius at 0.1 mm/rev feed rate. Figure 2 is shown that Ra value is reduced up to 90 from machining at 0.4 mm insert nose radius to

Learn More

PDF) Effects of Insert Nose Radius and Processing Cutting

It is seen that the insert nose radius, feed rates, and cutting speed have different effect on the surface roughness. The minimum average

Learn More

How to apply boring - Coromant

For best stability and hole quality, Insert nose radius and depth of cut. The nose radius, RE, is a key factor in boring operations. Avoid depths of cut smaller than 1/3 of the nose radius when finishing at small depths of cut. With a small nose radius, the radial cutting forces can be kept to a minimum, while utilizing the advantages

Learn More

Etech-252 midterm Flashcards | Quizlet

QUESTION 9 HW 1!!!! .4734. What is the dimension shown on the vernier caliper. (Make sure to read the top scale) QUESTION 10 HW 1!!!! 2.262. USE MACHINERY'S HANDBOOK SPEEDS AND FEEDS P 1026 -1055. Question 1 (table 1) Referencing feed rate and cutting speed for machining can sometimes be confusing (because of the huge array of sources), rather

Learn More

CNC turning - Nose radius selection - Cadem

Chip breaking depends on the nose radius and feed rate. At the same feed rate, a smaller nose radius gives better chip breaking. So to improve chip breaking, either increase the feed rate or reduce the nose radius. General rule for nose radius selection Use small nose radius for : small depth of cut, slender parts when you want to reduce vibrations

Learn More

Demystifying Insert Nose Radius Selection - BIG DAISHOWA

2/27 · The typical rule of thumb is to have a radial depth of cut one-half to two-thirds of the nose radius. For example, when using a 16 thou nose radius insert, leave a stock of 16-20

Learn More

Demystifying Insert Nose Radius Selection - BIG Kaiser

The typical rule of thumb is to have a radial depth of cut one-half to two-thirds of the nose radius. For example, when using a 16 thou nose radius insert,

Learn More

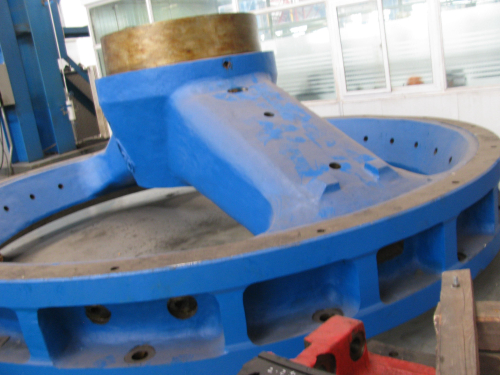

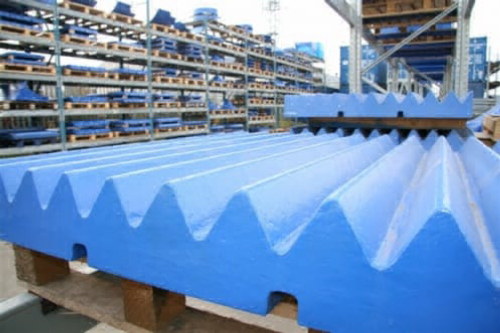

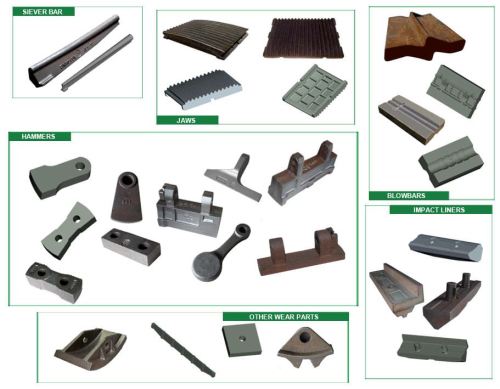

jaw plate price | when is a small insert nose radius recommended?

All kinds of crusher spare parts, jaw plate price, You can get more details about from mobile site on m.alibaba.com. Overview. Details. Recommended. .78 - .20. Min.Order: 1 Kilogram. All kinds of crusher spare parts, jaw plate price. Send Inquiry. Chat Now. Trade Assurance. Forum thread titles for "plate"

Learn More

Insert nose radius and radial force in CNC turning - Cadem

11/9 · Your selection of insert nose radius affects the force. Radial cutting force increases as the tool nose radius increases. As the picture shows, with a tool approach angle of 90

Learn More

Insert nose radius chart- for feed rate selection in turning

12/1 · Doubling the nose radius improves the surface finish twice (reduces the Rmax value by 50 %). You can use the insert nose radius chart above to quickly decide the feedrate

Learn More

How Insert Nose Radius affects the Output in Post Processor ... - Siemens

I just ignore the Nose Radius. But when I use NX, the nose radius I choose will affect the output program. With NX, with Nose Radius .031", it will output X5.027 Z12.098. and Nose Radius .062", it comes out X5.1448 Z12.129. If I want to output exactly what I want in manual, I have to change NX Nose Radius = 0.

Learn More

HP800 HEAD MACHINING | when is a small insert nose radius

The home of genuine PITBOSS® equipment.

Learn More