coal pulverizers

How To Maintain a Coal Pulverizer? (All You Need To Know

Common Faults Of Coal Pulverizer. Over Temperature Of Bearing Bush. Loud Noise During Gear Meshing. Cracks in Coal Mill Cylinder. Tips for Solving Coal Pulverizer Faults. Select the correct lubricating oil and use it reasonably. Adjust the Meshing of the Gears. Reduce the Noise. Prevent Cracks in the Cylinder.

Learn More

Coal Pulverizers - ASME - American Society of Mechanical Engineers

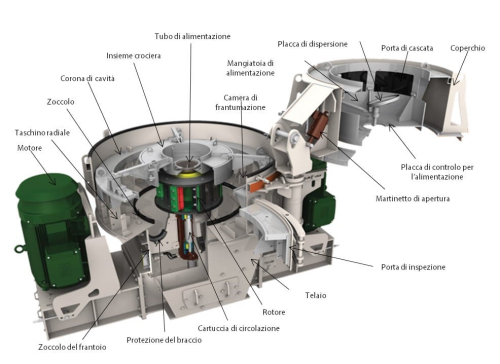

This Code applies to the pulverizing system as a whole, including all the component parts necessary to take the raw coal, hot air and tempering air at the system inlet, and deliver pulverized coal in proper mixture with air and/or flue gas at the desired temperature at the outlet of the system. About ASME Digital Books (PDFs)

Learn More

B&W Parts, Services and Programs for CE-Type Pulverizers / Mills

Roll Wheel Pulverizer B&W has designed, manufactured and placed in operation more than 1,100 roll wheel pulverizers, grinding a wide range of coals at power stations throughout the world. The B&W Roll Wheel® pulverizer has set the standard for high availability, reliable operation and low maintenance.

Learn More

Pulverizers 101: Part 3 - Storm Technologies, Inc

The coal enters the mill at about 80°F and then hot primary air flows over the. Primary airflow through a pulverizer is generally thought of simply as transport

Learn More

Coil Pulverizers for Boilers - Bright Hub Engineering

Aug 13, · Coal is pulverized before firing for achieving a stable and efficient combustion. Many types of pulverizers are used in boilers by different designers. History of pulverization The history of pulverization dates back as early as 1824 and

Learn More

CE-Type Pulverizers / Mill » Babcock & Wilcox

Roll Wheel Pulverizer B&W has designed, manufactured and placed in operation more than 1,100 roll wheel pulverizers, grinding a wide range of coals at power stations throughout the world.

Learn More

PDF Pulverizers 101: Part 3 - Storm Technologies, IncPDF

high temperatures in a low humidity environment, which is essentially what is done in a coal pulverizer. The raw coal is ground and exposed to a very low relative humidity. The coal enters the mill at about 80°F and then hot primary air flows over the Primary airflow through a pulverizer is generally thought of simply as transport air - the

Learn More

PDF Optimum Operation and Maintenance of EL PulverizersPDF

The procedure applied to extinguish a fire on an in-service pulverizer is as follows: 1. Increase the raw coal feed to the pulverizer to the maximum pulverizer capacity. 2. Make the transition from hot to cold air operation. Avoid making sudden changes in air flow through the pulverizer. 3. Monitor pulverizer outlet temperature.

Learn More

Holmes Coal Pulverizers - Gilson Company

Holmes Coal Pulverizer with Auger Feed (220V, 50Hz). Model: LC-502F. 1st Screen Plate *. Select 1st

Learn More

Coal Pulverizer Maintenance Improves Boiler Combustion - POWER Magazine

Acceptable standards for best low-NO x burner performance are coal fineness of 75% passing a 200-mesh sieve and less than 0.1% remaining on a 50-mesh sieve. Fuel balance should be within the range

Learn More

Coal Pulverizers, Benchtop Units, Auger or Manual Feed - Gilson Co

Holmes Coal Pulverizers are bench-type units that perform well in reducing coal or coke from No. 4 to No. 60 sieve size. Models are available with manual or auger feed. All units are constructed of painted steel and cast iron, and have a one-piece balanced rotor with hard coated hammers, driven by 1hp, single-phase motor with overload protection.

Learn More

Pulverizer - Wikipedia

For example, a pulverizer mill is used to pulverize coal for combustion in the steam-generating furnaces of coal power plants.

Learn More

Pulverizer / Mill Upgrades » Babcock & Wilcox

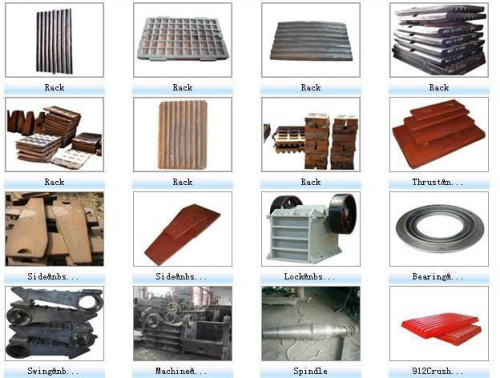

Through a strategic alliance, B&W provides advanced coal pulverizer replacement parts from Magotteaux, a leading supplier of high wear, severe duty castings and differentiated wear solutions. This supplier relationship combines the unique benefits of Magotteaux’s metallurgical expertise and experience in high wear, abrasion-resistant material

Learn More

PDF Coal Pulverizer and Coal Crusher Reliability | MobilPDF

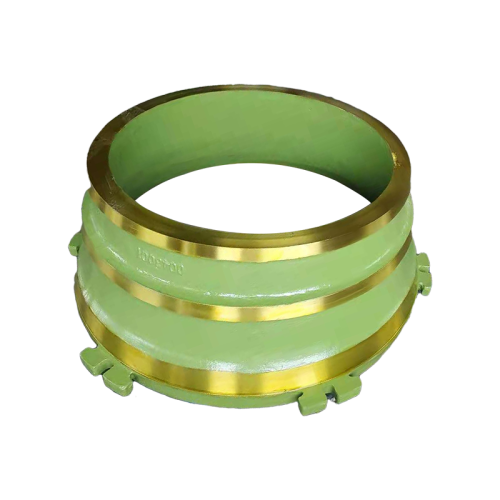

Coal pulverizers/crushers Industries • Power generating stations Key applications • Gears — worm and helical, bevel combinations • Roller element bearings Challenge: Coal pulverizer reliability. Repairs and even routine maintenance are time-consuming and costly due to difficult operating conditions. Operating temperatures can be high and

Learn More

A Comparison of Three Types of Coal Pulverizers - Babcock

As the mill rotates, the balls cascade and pulverize the coal by impact and attrition. The pulverized coal is then conveyed by air to centrifugal classifiers. Properly sized pulverized

Learn More

Coal pulverizer - Hardox Wearparts

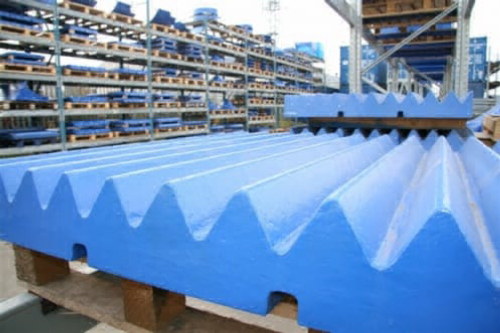

The coal pulverizer is applied to crush the coal to an average size of 0.074 mm powder. At the entrance of coal pulverizer, the temperature would be between 160 C to 393 C. The blowing speed is 50 to 55 m/second. When the high Cr cast steel (48-58 HRC) liner plate is used, the service life is 1.5 to 2 years, but spalling would be an issue.

Learn More

Coal Pulverizers Market Size 2022: Expansion Strategy ... - MarketWatch

The Expresswire) -- The Global “Coal Pulverizers Market” report covers leading companies analysis, which incorporates gross profit, volume,

Learn More

Coal Pulverizers - ASME - American Society of

This Code applies to the pulverizing system as a whole, including all the component parts necessary to take the raw coal, hot air and tempering air at the system inlet, and deliver

Learn More

PULVERIZER ROLLS - Industrial Wear Solutions

With over 35+ years of experience, RPM is the industry leader in rebuilding coal pulverizer rolls. RPM offers a variety of chrome carbide overlay options

Learn More

Holmes Coal Pulverizers - Measur

These bench-type pulverizers are recommended for reducing coal or coke from No.4 to No.60 sieve size. Light duty LC-350 has manual feed from the 1L feeder

Learn More

Coal Pulverizers | Xtek, Inc

Mineral Processing Coal Pulverizers Pulverizer gearboxes are large and come with a significant price tag. Exchanging them requires a large dose of planning.

Learn More