cheek plate design

Cheek Plates High Resolution Stock Photography and Images

Helmet made of several soldered bronze plates with a high comb and protruding peak and neck guard. Plume holder at the left front,hinges for the missing cheek pieces on both sides. Some traces of age,light patina. Height 25 cm. Exceptionally rare helmet,which belongs to the traditional armour of the Moro warriors.

Learn More

ULTIMATE CAPACITY OF PAD EYES USED FOR LIFTING

main types of design geometries for pad eyes are described in NORSOK R-002 lifting stand - ard [1]. Type 1 is made of plate, with a uniform thickness, as shown in Fig, 2. Type 2 is made of cheek plates attached to the main plate by a fillet weld, as shown in Fig. 2, while type 3

Learn More

Cheek Plates 101 - What's Wrong With This Picture?

13/05/2022 · Apr 15, 2020. #1. Moving the head mount forward on this a full 6" after swapping out the 320 lbs 130 HP Subaru for a 170 lbs 160 HP Yamaha, permanently leaving elephant Soobie mother-in-law on ground permanently Just finished up the Visio cheek plates redesign this evening, thought to share with you the old problems that jump out that need

Learn More

OPTIMUM ANALYSIS OF OFFSHORE STRUCTURES LIFTING

Padeye design and analysis plays an important roles during the lifting, load out and installation of heavy structures. This study addressed the different dynamic The effective thickness of the cheek plate can be increased to 100% with proper fabrication and welding sequence. Finite Element analysis is a good tool to have better

Learn More

Medieval Weapons and Armour: Helmet. Types of Helmets, Facts

The Greeks created a design that has been featured in countless movies, the Greek Hoplite helmet or Corinthian helmet, which covered most of a warrior’s face and had huge cheek plates and a long nasal that left very of the face exposed. Earlier Roman helmets were based on Celtic designs. However, in the late 3rd century, a complete break in

Learn More

Flanges (Cheek Plates) - ULTRA TEC Manufacturing, Inc

for Precision Saws with 0.5 inch arbor (spindle). Flanges (Cheek Plates) are sold as a pair. They reduce the lateral wander of peripheral (OD) blades under

Learn More

Padeye Design - Structural engineering general discussion - Eng-Tips

19/02/ · MVPs. zaxen (Structural) (OP) 15 Feb 12 23:58. I am designing a single padeye plate (no cheek plates) with a single shackle pin going through it. I am accouting for the two most

Learn More

Cheek Plate Patterns | Library of Congress

Title Cheek Plate Patterns Contributor Names Harrell, Alfred (Photographer) Created / Published

Learn More

Lift Design with cheek plate

Lift Design - With Cheek Plate 1- IMPUT: 1.1 - WORK LOAD: Qc = 0.800 tf 1.2 - IMPACT LOAD: I = 1.25 1.3 - NUMBER OF SLINGS: Nc = 2.0 cable(s) 1.4 - SLING

Learn More

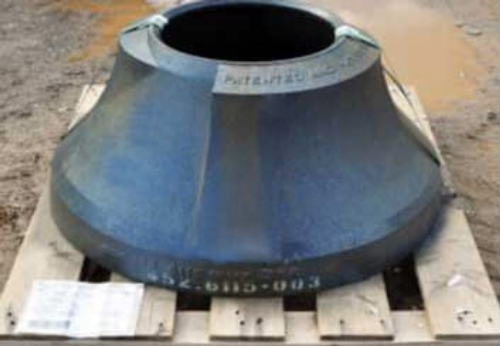

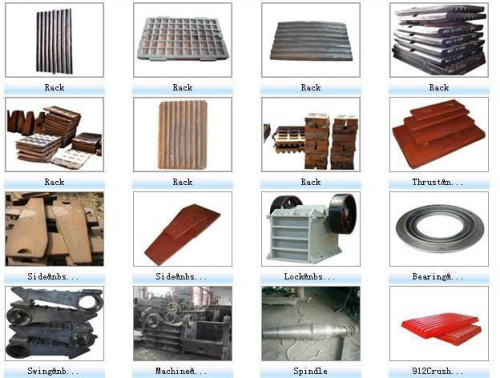

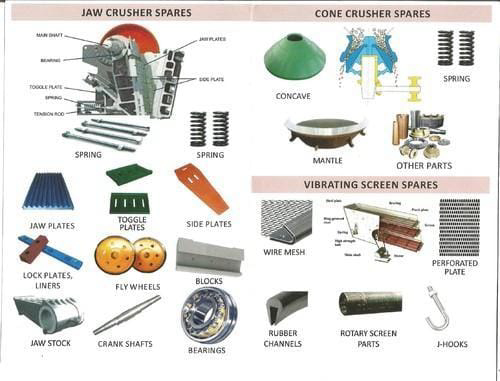

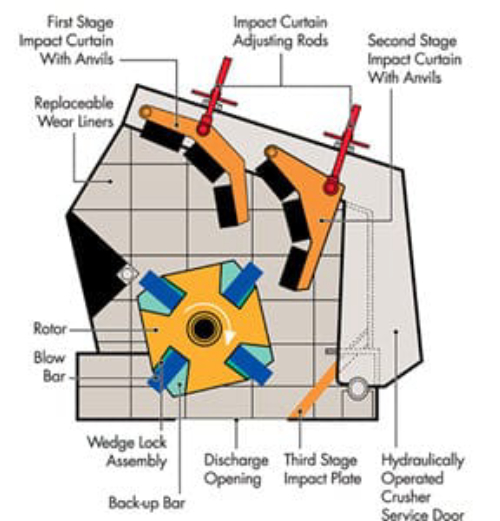

PDF C series jaw crushers Wear parts application guidePDF

piece jaw die design. A 1 piece jaw design is now also designed for large crushers (C110, C120, C125, C140, and C160). Upper cheek plate Lower cheek plate Movable jaw Fixed jaw 6 5 4 3 2 1 0. 10 Accessories Intermediate plate An intermediate plate can be used when feed capacity is low (empty cavity), feed size

Learn More

Standard padeye CAD drawing ready for cutting (dwg, dxf, pdf

Standard pad eye design suitable for lifting and seafastening applications. (8) Plate thickness as per drawing and padeye weight as table below

Learn More

PDF Ultimate Capacity of Pad Eyes Used for Lifting Operations: Experimental ...PDF

Type 1 is made of plate, with a uniform thickness, as shown in Fig, 2. Type 2 is made of cheek plates attached to the main plate by a fillet weld, as shown in Fig. 2, while type 3 consists of partly connected boss by full penetration welds as shown in Fig. 2. Shackles are made up of a U-shaped body and a pin, often secured with a bolt.

Learn More

LASHING PADEYE DESIGN - SpreadsheetConverter

diameter of cheek plate, d, = mm. thickness of cheek plate, t, = mm. distance pin outer to shackle, H, = mm. Jaw Width of shackle, B, =

Learn More

Padeye engineering tool development - TU Delft

The main plate is conducted with a pair of cheek plates to stiffen help in the design and strength check of a diversity of structures.

Learn More

PadEye Calculator | shackle compatibility & capacity | CalQlata

1) Enter design load including factors ( F) 2) Select a shackle size from the 'SWL' list 3) Enter cheek-plate and pin-hole clearances ( C & Cᴾ) 4) Enter a maximum allowable stress for the padeye plate ( σ) 5) And a few other dimensions (cheek-plate thickness, Young's modulus and weld joint factor)

Learn More

CHEEK PLATE LOWER | altec dc1217 parts manual

A&S produces manganese wear liners and accessories for most crushing brands including , , , Cedarapids, , Plate 200421 Jaw Plate 200422 Jaw Plate 46590860 Jaw Plate 46591200 C110 JAW PLATES Cheek Plate Upper 901531 Cheek Plate Lower PDF pipe - tube - bar. - the perfect choice in stainless.

Learn More

US5222886A - Cheek plate for a vane pump - Google Patents

It is an object of the present invention to design a cheek plate such that it can be manufactured at low cost. Specifically, fewer steps of manufacture are

Learn More

C series jaw crushers Wear parts application guide

piece jaw die design. A 1 piece jaw design is now also designed for large crushers (C110, C120, C125, C140, and C160). Upper cheek plate Lower cheek plate Movable jaw Fixed jaw 6 5 4 3 2 1 0. 10 Accessories Intermediate plate An intermediate plate can be used when feed capacity is low (empty cavity), feed size

Learn More

Padeye Design - Structural engineering general discussion

I am designing a single padeye plate (no cheek plates) with a single shackle pin going through it. I am accouting for the two most likely

Learn More

Why skewing is not beneficial for your HPGR - Outotec

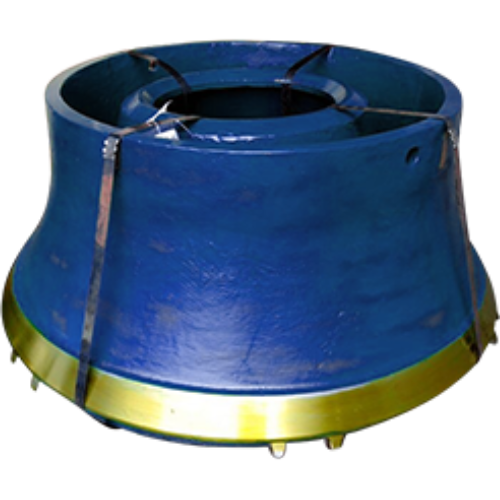

Traditional cheek plates vs. flanged roll design #3 - Skewing helps to even pressure across the full width of the roll. All machines with static cheek plates are designed to control skewing via the hydraulic system. Pressure is reduced on the skewing side of the roll with the smaller grinding gap (distance between the two rolls) in order to

Learn More

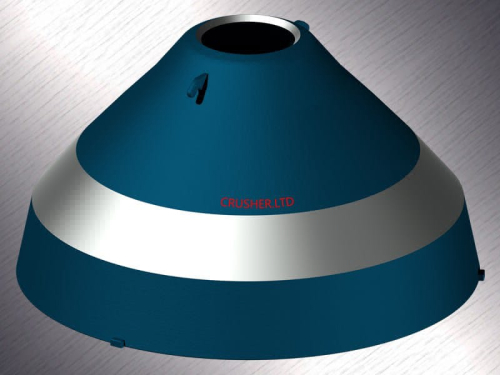

FatBoy cheek plate - Storyblok

Increased lifetime. Provides longer lifetime due to new design and new material (high alloy austenite). Quality of production.

Learn More