jaw crusher pdf

PE SERIS JAW CRUSHER

DMP series Mobile jaw crusher plant is ideal for: • Demolition and recycling Quarrying and surface mining Road construction Civil engineering contractors Aggregate production Open cast coal mining • • • • • 7 ZHENGZHOU DINGSHENG ENGINEERING TECHNOLOGY CO.,LTD ADDRESS:National HI-TECH Industry Unit B Torch Building, Zhengzhou,China.

Learn More

Mini Jaw Crusher | Sepor, Inc

SEPOR, INC. 718 N FRIES AVE. WILMINGTON, CA 90744. 310 830 6601. Fax: 310 830 9336 [email protected]. OPERATING AND MAINTENANCE MANUAL. MINI JAW CRUSHER

Learn More

PDF Design and Construction of Rock Crushing Machine from Locally Sourced ...PDF

functioning Jaw crusher. Most of these components are discussed below. Moveable jaw stock The moveable jaw stock is the main moving part in a jaw crusher. It forms the moving side of the jaw, while the stationary or fixed jaw forms the other. It achieves its movement through the eccentric movement of the crusher main shaft. It is the back and

Learn More

jaw-crushers-1.pdf - International Journal of Modern

Single and double toggle jaw crushers are constructed of heavy duty fabricated plate frames with reinforcing ribs throughout. The crusher‟s components are of high strength design toaccept high power draw. Manganese steel is used for both fixed and movable jaw faces. Heavy flywheels allow crushing peaks on tough materials.

Learn More

Jaw Crusher Handbook | Stone Crusher PDF - JXSC Mine

1. Before starting, all jaw crusher parts must be fastened installed. The tail traction spring is suitable loose, and the engine oil is installed in the swing bolster. 2. Jaw rock crusher must test

Learn More

jaw crusher pdf drawings - KOOKS

jaw crusher that employs the simple technology of a four bar mechanism, and design a small scale mechanized jaw crusher for crushing the stones into aggregates. This mechanism will help to evaluate its effectiveness in comparison with other different types of mechanisms in use especially the double toggle and the modified single toggle mechanism.

Learn More

Jaw crusher - SlideShare

Jaw Crusher • Jaw crusher is a type of crusher which produces coarse particle. • Feed size of the jaw crusher is 1500mm-40mm and the product size is from 50mm-5mm. • Compressive strength of jaw crushers is 320 mega Pascal. • Rpm for jaw crusher is between 200- 400. 6.

Learn More

CJ411 Single-Toggle Jaw Crusher For High Production

CJ412 Jaw crusher. CJ412 single-toggle jaw crusher is engineered for the toughest applications thanks to its heavy-duty design. Characterized by an attention to detail in its design and manufacture, this machine is an excellent choice when you need high production and low total cost. Email us Request a quote.

Learn More

A REVIEW - African Journals Online

A review on the design and operations challenges of a single toggle jaw crusher is presented. Strength and fracture toughness of the material to be crushed

Learn More

PDF C Series Jaw Crushers - hvmachinery.comPDF

crushers know that not all jaw crushers are the same! Fast and safe setting adjustment systems All C Series crushers are equipped with a proven, rugged and fast wedge setting adjustment system. The wedge setting adjustment is simpler, much safer and faster than outdated shim adjustment systems. The crusher's setting can be manually adjusted with

Learn More

PDF Engineered for the toughest feed materials ® C Series™ jaw crushersPDF

C Series jaw crushers have a strong pinned and bolted, non-welded frame construction and the highest power ratings in each size class, which brings benefits to stationary, underground and mobile crushing applications. They are designed to the highest safety standards to make the use and maintenance as easy as possible.

Learn More

PDF Crushing and screening solutions - Agg-NetPDF

C Series jaw crushers were originally developed to crush the hardest ores and rocks so they perform extremely well also in less demanding applications, such as soft rock, recycling and slag. Benefits • Reliability • Productivity • Easy installation • Safety 10 11 C Series jaw crushers are engineered to deliver maximum

Learn More

PDF TECHNICAL NOTES 5 CRUSHERS - Mineral TechPDF

Jaw and gyratory crushers are used mostly for primary crushing. They are characterized by wide gape and narrow discharge and are designed to handle large quantities of material. The capacity of the crusher is determined by its size. The gape determines the maximum size of material that can be accepted.

Learn More

Jaw Crushers JW Series - Corporation

these durable crushers utilize heavy duty components for optimum operation and long life. Typical applications for our single toggle jaw crushers are.

Learn More

PDF Handbook of Crushing - TerraSource GlobalPDF

both surfaces. Jaw crushers using this method of compression are suitable for reducing extremely hard and abrasive rock. However, some jaw crushers employ attrition as well as compression and are not suitable for abrasive rock since the rub action accentuates the we crushing surfaces. As a mechanical reduction method, compression should

Learn More

Engineered for the toughest feed materials ® C

C Series jaw crushers have a strong pinned and bolted, non-welded frame construction and the highest power ratings in each size class, which brings benefits to stationary, underground and

Learn More

A REVIEW ON STUDY OF JAW CRUSHER

and improving the design quality of jaw crusher. There are many researcher work done by (PDF) relationships along with interactive failure of.

Learn More

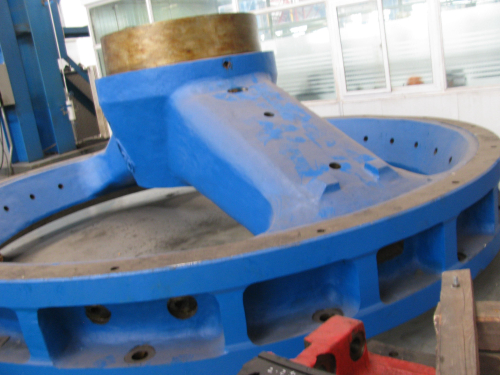

Manufacturing and refurbishing of jaw crushers - RocketCDN

With each rotation of the eccentric shaft the swing jaw opens and closes on rock which is fed into the crusher chamber, crushing the rock in a series of bites.

Learn More

PDF Crushing and Screening Handbook - AusIMMPDF

the crusher and scalp out fi nes. Primary gyratory crushers - ideally suited to all high-capacity primary hard rock crushing applications. Jaw crushers - we have more installed jaw crushers than anyone in the world. The lead-ing choice due to their high reduction ratio and heavy duty design. Cone crushers - capacities available to suit all

Learn More

Computer Aided Design of Jaw crusher” - Metallurgist

The mechanism of jaw crusher is based on the concept “crushing without rub ”. Jaw crushers consist of two jaws. One fixed and the other reciprocating. The opening between them is

Learn More

PDF C Series jaw crushers - International Crusher SolutionsPDF

The following factors will enhance crusher capacity and performance: 1. Proper selection of the jaws. 2. Proper feed gradation. 3. Controlled feed rate. 4. Sufficient feeder capacity and width. 5. Adequate crusher discharge area. 6. Discharge conveyor sized to convey maximum crusher capacity. Indicative product gradation

Learn More