cone crusher vs gyratory crusher

Gyratory Crusher Pro - thyssenkrupp Mining Technologies

The main characteristic of jaw gyratory crushers is their enlarged feed opening which is located on one side of the crusher only. It is normally

Learn More

Top Service Gyratory Crusher TSUV

The lowest cost per tonne of product processed Crushing just got harder. With low grade ore deposits requiring higher power and higher throughputs than ever

Learn More

keuntungan agregat vsi crusher

crusher agregat vsi atau kerucut Dapatkan Harga Jaw Crusher Kelebihan mbmttc CS Cone Crusher CS Cone Crus her is a kelemahan jaw. cone crusher crusher dampak vs Vsi Crusher Kerucut Vs stockash Kerucut Crusher menjual harga Dampak VSI crusher kerucut vs keuntungan dari crusher gyratory 171 coal russian Kutipan khusus keuntungan .

Learn More

Thread: Difference between Cone & Gyratory Crusher

Gyratory crushers are for primary crushing. Normally used for Crushing crushing minerals as mined. The size of crusher bowl will match size of

Learn More

gyratory crusher vs cone crusher

WhatsApp: https://wa.me/8613621919955?text=Pls+send+us+this+message+first%2C+then+we+will+arrange+for+the+right+sales+engineer+to+serve+you%21+Your+Unique+Co

Learn More

Gyratory Crusher Explained - saVRee

gyratory crushers or ; jaw crushers. It is often the case that there will be only one crusher installed, and this will be referred to as the ' ; Primary Crusher'.

Learn More

Cone Crusher VS Gyratory Crusher - JXSC Mine - JXSC Rock Crusher

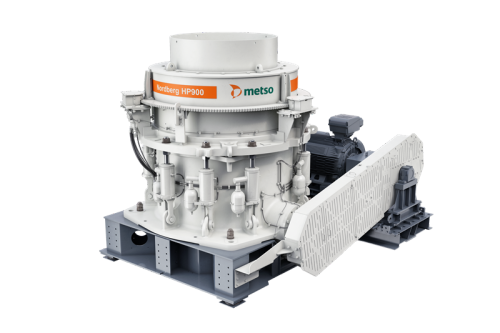

The cone crusher has 2.5 times higher rotating speed and 4 times larger swinging angle than the gyratory crusher, so the ore is impacted quickly. Therefore, it is advantageous to the ore crushing, the crushing efficiency is high. 2. Different applications. In large quarries, gyratory crushers are often used as primary crushers.

Learn More

Selecting the Right Crushing Equipment | Agg-Net

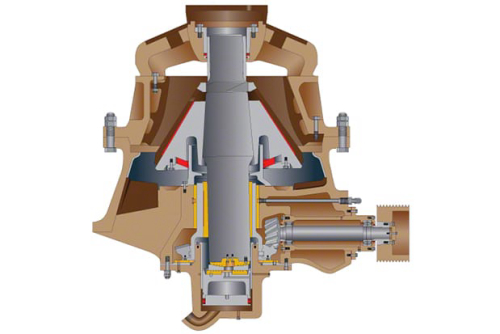

Cone and gyratory crushers are both gyrating-shaft machines. They have a main shaft that gyrates and provides the crushing motion. Crushing takes place between

Learn More

Difference between Cone & Gyratory Crusher

Jan 28, · Gyratory crushers are for primary crushing. Normally used for Crushing crushing minerals as mined. The size of crusher bowl will match size of boulders. Cone crushers are used for secondary or tertiary crushing for making a cubical product for feeding to process equipment. vinayak sathe 15, Rangavi Estate, Dabolim Airport 403801, Goa, India

Learn More

Difference Between Jaw Crusher and Gyratory Crusher - JXSC

The feeding size of the gyratory crusher is larger than the jaw crusher, and the output size is smaller and more uniform. The content of needle-like particles in discharge is less than 10%. The raw material can be poured from the conveyance directly into the feed port. It doesn’t need the feeder equipment.

Learn More

gyratory crusher working G10SEC V-BELT PULLEY SPC 530/8, ECCENTRIC

G10SEC TRMNL PLUG BUZ12-S 1756-a10 dimensions parts of stone crusher spare bush for a cone crusher mobile crusher parts. High-Speed Gyratory Crushing --> Fine Cone Crushers. Malaysia crusher machine,Gyratory cone crushers,Jaw crushers Gyratory crusher type KB 137-190 (54″-75″ installed in a semi-mobile crushing plant working in a copper ore

Learn More

cone crusher vs gyratory crusher - Crusher production line of large

Specialized in Cone Crusher Machine 30 Yrs, 500+ Cases Here, More Details! High Power Cone Crusher Designed Specifically For Small-To-Medium Sized Mining Projects. Types: Complete Crushing Plant, Crushing Equipment Stone Crushing Machine Different Types of Stone Crushers Good For Ballast, Granite, Basalt. Cone Crusher Project Case Cone Crusher Customer Case Offer A-Z Solutions, Local

Learn More

Crusher Gyratory Bijih In Vietnam

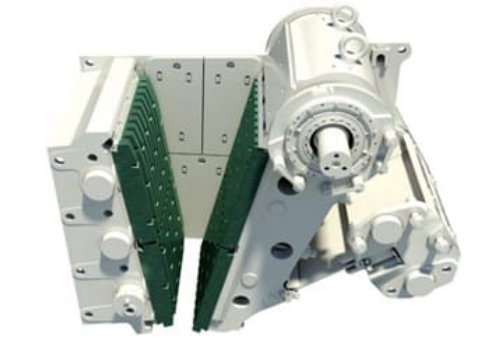

gyratory crusher crushing capacity in Vietnam. The three types of crushers most commonly used for crushing CDW materials are the jaw crusher, the impact crusher and the gyratory crusher (Figure 44) A jaw crusher consists of two plates, with one oscillating back and forth against the other at a fixed angle ( Figure 44(a) ) and it is the most widely used in primary crushing stages ( Behera et al

Learn More

jaw crusher,gyratory crusher vs cone crusher in mining plant

Dec 30, · Firstly in Gyratory crusher the outside crushing surface flares in from top to bottom but in Cone crusher it is vice versa. Hence area of discharge gets increased Secondly,upper crushing surface can be lifted in cone crusher but not in gyratory crusher. Cone crusher can intake finer as well as coarser feeds.

Learn More

between gyratory crusher and a cone crusher

4 24 Crusher Grinder Novamining Novamining Hence vibrating screens are deployed in between different stages of the crushers The essential difference is

Learn More

Everything You Need to Know About Rock Crushers

Cone crushers can accept medium-hard to very hard and abrasive feeds that might be dry or wet, though not sticky (whereas gyratory crushers are better at

Learn More

Cone Crushers Vs Gyratory Crusher

Portable mobile jaw crusher is developed according to novel series stone crushing equipment's design idea, the adaption Mobile Jaw Crusher Vibrating Feeder is a kind of linear-direction feeding equipment, in the mineral ore &rocks processing plants, it can send

Learn More

cone crushers vs gyratory crushershtml price

Jan 15 · Cone crusher looks like gyratory crusher but without a steep crushing chamber Just like jaw crusher it is also a compression type crusher whose reduction ratio is 41 to 61 When cone crusher works it uses the force between moveable mantle and stationary bowl liner to crush material. Zhengzhou, Henan, China.

Learn More

Gyratory Crushers - SolidsWiki

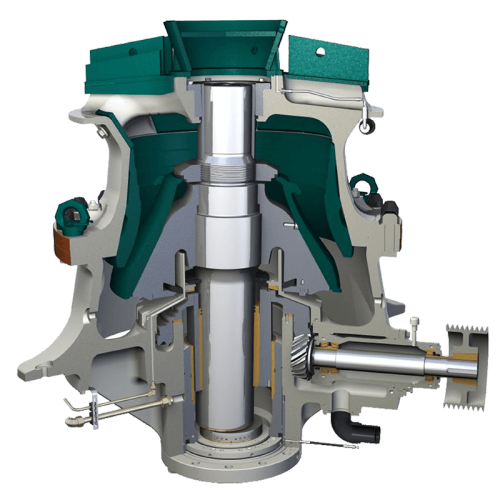

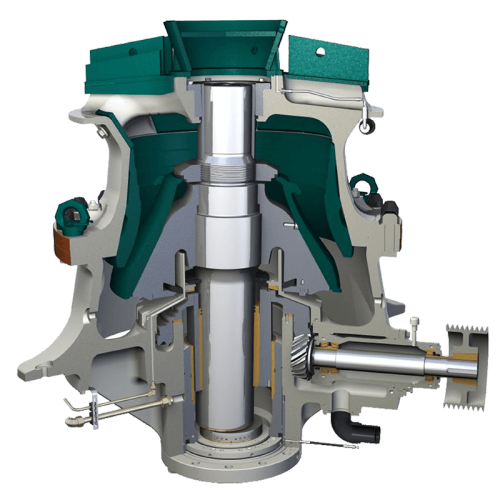

A Gyratory Crusher is a large crushing machinery, using the gyratory sports in casing cone cavity of crushing cone to produce extrusion,

Learn More

Difference Of Gyratory Crusher And Cone Crusher-HN Mining

A Gyratory Cone Crusher is one of the main types of primary crushers in a mine or ore processing plant. Gyratory Cone Crusher are designated in size either by the gape and . Chapter 5. Gyratory and Cone Crusher 2fishygirl on Scribd . 5.2 A conveyor belt fed a Run-of-Mine iron ore to a gyratory crusher, which had a gape of 356 cm.

Learn More

Should I Choose an Impact Rock Crusher or Cone Crusher?

Impact Crusher vs. Cone Crusher – What's the Difference? · Impact vs Compression. Rock crushers are first categorized by the general crushing

Learn More