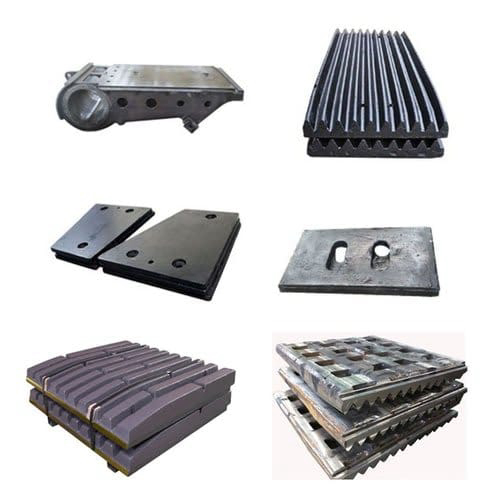

wear plates for impact crusher

Manganese Wear Plate, Cone Crusher Spare Parts | John Heine

Jaw and Cone Crusher Liners / Manganese Wear Parts to suit most Crushers/Screens in the different grades from 14% to 22% Manganese. Very High Quality 22%

Learn More

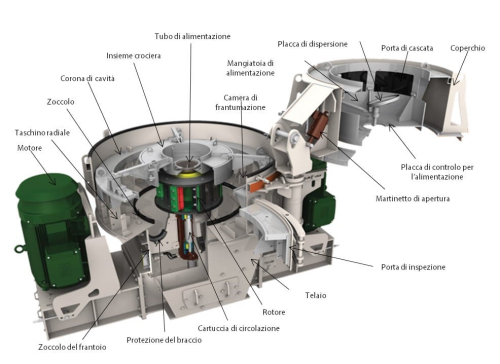

Impact crusher parts - Outotec

Available wear parts · Rotor tip sets · Back-up tips · Tip / Cavity wear plates · Upper and lower wear plates · Top and bottom lipped wear plates · Feed tube and feed

Learn More

IMPACT CRUSHER WEAR PARTS - Precision Casting

Impact Crusher is a crushing machine that uses impact energy to crush materials. When the machine is working, motor drives the rotor rotates at a high speed. When the material enters

Learn More

wear plates for impact crusher - PSYCHOTERAPIA ONLINE

The impact crusher wear parts are an important part of crusher and need to be replaced on schedule. In the industry, it is also known as a crusher plate. We can provide various types of impact crusher wear parts, such as blow bars and impact plate, we can also be based on the drawings provided by customers to create different materials products.

Learn More

Crusher Wear Part Photos - Kenco Engineering Inc

Kenco TCI studded wear plates, easily rotated to all wear positions, allow quick repairs in Cedarapids hammermills.

Learn More

Crusher Spare Parts - Jaw Plates Manufacturer from Udaipur

Toggle Plates that are widely used in stone crusher machines. Our toggle switch plate is Manufactured from the finest quality raw materials to add durability.

Learn More

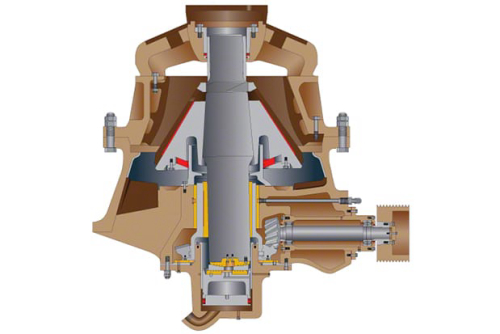

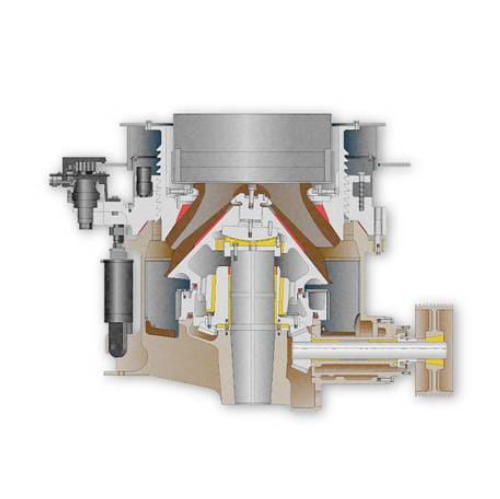

wear plates for impact crusher

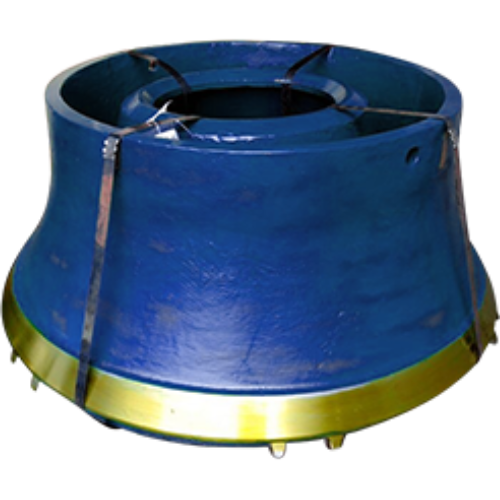

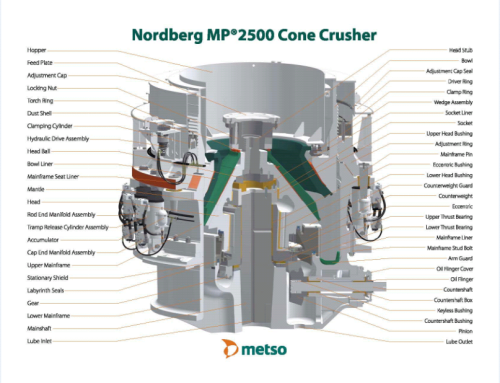

wear plates for impact crusher Construction, Working and Maintenance of Crushers for. The gyratory crusher is mainly used in rock that is abrasive and/or has high compressive strength. The crusher is the workhorse of the hard rock crushing industry. A gyratory crusher uses a mantle that gyrates (rotates) within a cone shaped inner surface lined

Learn More

Impact crusher wear parts - SWB - Stahlwerke Bochum

SWB wear parts are used for crushing mineral resources like stone, ore and coal as well as crushing secondary resources like brick and construction remnants

Learn More

REFERENCE GUIDE

knowledge of crusher wear parts and guide you when selling wear parts to your customers. Maximum distance between jaw plates for a given setting (the.

Learn More

Blow Bar, Impact Plate, Impact Crusher Wear Parts for Sale ... - Willing

The main wearing parts of Impact Crusher are blow bars and impact plates, with special heat-treatment, the hardness of our blow bar can reach to HRC58~HRC63. The product mainly uses high manganese steel material, for example Mn14Cr2, Mn18Cr2, Mn22Cr2 and so on. Willing's blow bars and impact plates are widely used on mining, construction

Learn More

What Is Impact Plate |Wear Liner - Quarrying & Aggregates

The impact plate (wear liner) is the second vulnerable part in the impact crusher to the plate hammer, which bears a large impact force.

Learn More

How does an impact crusher work? | RUBBLE MASTER

Impact crusher hammers, wear liners, and impact plates are consumables and need to be replaced frequently. Wear items are chewed up in the crushing process and need to be monitored and changed frequently. The higher the abrasion, hardness, and fines-content the faster the wear.

Learn More

Impact Crusher Wear Parts – Crusher Wear Parts – Hongfei

Impact Crusher is a crushing machine that uses impact energy to crush materials. When the machine is working, motor drives the rotor rotates at a high speed. When the material enters

Learn More

Spare parts - ROC IMPACT

ROC IMPACT offers a wide range of adaptable and mechanical wear parts for many brands. And a very comprehensive Fixed and swing jaw plate jaw crusher

Learn More

JAW PLATES - Precision Casting

Description Jaw Plates or Jaw Dies are the most frequently replaced wear parts of the jaw crusher, so the quality of the jaw die is one of the most important factors that determine the crushing efficiency and operating time. A set of jaw plates are composed of the movable (swing jaw) and fixed jaw plate (stationary jaw).

Learn More

Jaw crusher wear and spare parts | Mallas y Cribas

1. Jaws · 2. Fuse Plate · 3. Jaw securing wedges · 4. Antiwear lateral plates.

Learn More

wear plates for impact crusher | crusher countershaft bushing flat pin

Impact Plate, Power Crusher (Model PC12071) I1270-09-03-00DB: Impact Plate, Hartl (Model 1275) H1275.10.04.00: Feed Chute Liner,Power Crusher (Model PC12071) Tip Carrier Wear Plate Center (Reversible, With Hardware Kit) B96-39-4150L: Tip Carrier Wear Plate Outer (Reversible, With Hardware Kit) 10 Ways to Get the Most Out of Your Mobile

Learn More

What are the Materials of the Jaw Crusher Plates and Which is Better

However, due to the structure of the crusher, the opening angle between the movable and fixed jaws is too large, which is easy to cause abrasive sliding and deformation due to deformation. Insufficient hardening makes the surface hardness of the jaw plate low, short-cut abrasive cutting, and the jaw plate wears faster.

Learn More

wear plates for impact crusher | laboratory laboratory jaw crusher

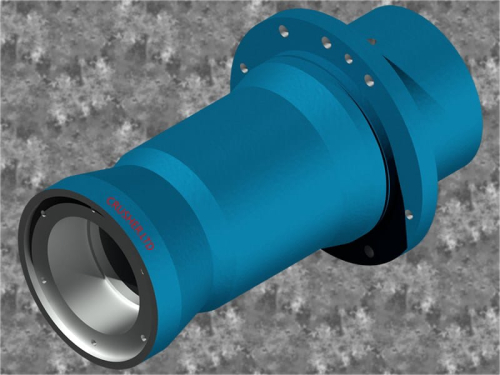

Abrasion resistant wear part for vsi crusher rotor. An abrasion resistant wear plate is mountable within a rotor or a vertical shaft impact crusher to protect the rotor from material fed into the

Learn More

VSI Rotor and Wear Parts - KoneCarbide

Vertical Shaft Impact Crusher (VSI) Rotor and Wear Parts · B96394135A: Upper Wear Plate (3 pieces) · B96334140A: Lower Wear Plate (3 pieces) · B96394060B:

Learn More

Crusher Impact Plates - SHANVIM

Impact plate is one of the primary wearing parts of an impact crusher. Impact plate made in shanvim® has brought owners huge maintenance cost savings.

Learn More