cone crusher liner change

cone crusher liner change | high quality cone crusher wear copper

Change CSS. Replace the cone crusher liner. Tags: Common faults Cone crusher Solutions. Written by Rayco. 20 years of experience in the mining and construction aggregate industry, to provide advice on your mining or quarry projects. Leave a Comment Cancel. Your email address will not be published.

Learn More

When do you change cone liners? - ELRUS Aggregate Systems

Click the image below to earn more. ELRUS Manganese Cone Liners. Topics: Downtime, crusher spare parts, gravel crushing and screening costs,

Learn More

Cone Crusher Liners For Popular Brands With Various Material

Through our application-driven, site-specific engineering capabilities, our offering of replacement cone crusher parts of most any origin has gained acceptance

Learn More

Change crusher liners - Wear Parts For Industry | Qiming Casting

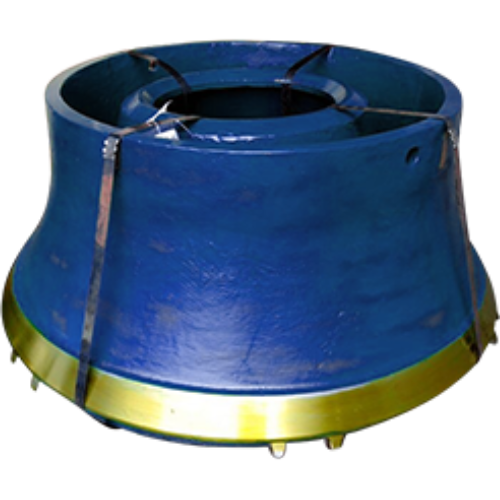

It is an important thing when to change crusher liner, so as to avoid damage to the liner seating surfaces of the crusher bowl, concave and mantle must be replaced before they are worn through. In some conditions with good quality wear parts , approximately 50% of the liner weight is consumed when liners are worn out.

Learn More

cone crusher liner change | differential pressure switch for water pump

As cone crusher liners wear, the operator threads the bowl inwards, price of the liner change you should consider changing the liners. Wholesale Price Cone Crusher Liners. 3. When changing the lower copper sleeve of the movable cone and the eccentric sleeve bushing, you must first check whether the inner diameter of the movable

Learn More

cone crusher liner change | puzzolana 200 tph cone crushers shaft sleeve

cone crusher liner change. Analysis of the Wear Failure of Cone Crusher Liner at. The moving cone (liner) we sampled was just removed from the cone crusher and shipped back in time. The broken cone crusher liner is cut into large samples by oxygen-acetylene flame, and 4 samples are taken from top to bottom. The size of the sample should be such

Learn More

Cone Crusher Wear Parts - Columbia Steel Casting Co., Inc

OEM liners are based on average conditions, and few cone crushers work under replacement for zinc in both portable and permanent crusher applications.

Learn More

Jaw Crushers - Best Models for 2022 - 911 Metallurgist

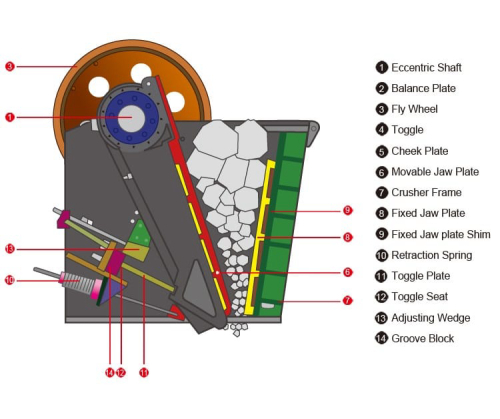

Replacement Jaw Crusher Liners 3″ x 4″. US $650. Add to cart. jaw crusher parts list. jaw crusher drawing. Agg-Net.com. 736 subscribers. Jaw Crusher.

Learn More

Failure to adequately maintain crushers comes at a high price

As cone crusher liners wear, the operator threads the bowl inwards, price of the liner change you should consider changing the liners.

Learn More

Selecting A Long Life Crusher Liner - Quarry Magazine

While all cone and gyratory crushers differ somewhat in design, most liner changes are basic. A cone liner change for a remote-adjust cone

Learn More

Cone Crusher Liners: What To Choose And When To Change - KeepandShare

Selecting a Cone Crusher liner There are numerous liners for both fine and coarse feeds. But which one you select will depend on a number of elements. The most crucial factor when it comes to Cone Shredder Parts selection is the feed. You must have a graded feed entering the crushing chamber. A well-graded feed is generally considered as:

Learn More

GYRATORY CONE CRUSHER, CRUSHING IRON ORE WITH NEW

About Press Copyright Contact us Creators Advertise Developers Terms Privacy Policy & Safety How works Test new features Press Copyright Contact us Creators

Learn More

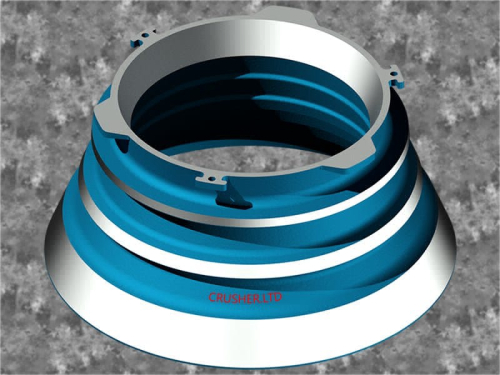

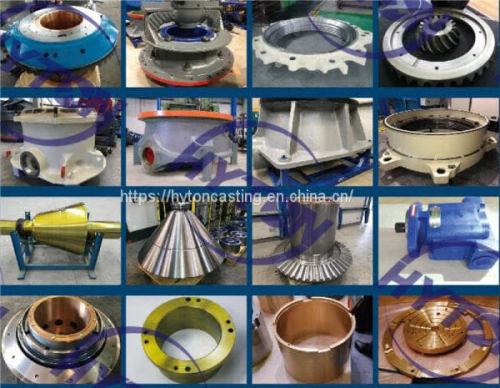

CSP Cone Crusher Wear Parts - Cast Steel Products

CSP Cone Crusher wear parts offering consists of replacement and custom design wear parts for cone crushers, including: Mantles, Bowls, Concaves, Feed Cones, Main Frame Liners, Protection Cones, Arm guards, Torch rings, Distributor caps, and Crusher backing. FEATURES & BENEFITS

Learn More

Replacing the liner of a HP cone crusher - Outotec

Jun 09, · The HP cone crusher is a very important piece of equipment in a crushing plant. It can operate as a secondary, tertiary or quaternary crusher, depending on the crushing process.

Learn More

Liner change solves heat issue; improves production

its cone crusher led a copper mine to contact FLSmidth. A new liner profile solved the challenge and improved the site’s overall performance. WE DISCOVER POTENTIAL Results at a glance

Learn More

Astec Kodiak® Cone Crushers - Astec

A unique roller bearing design reduces operating expenses by up to 50 percent while improving production and energy efficiency compared to bushing crushers. The Kodiak ® cone crusher meets coarse and fine crushing application requirements and offers on-the-fly adjustability for easy operation. 7:41.

Learn More

Cone Crusher - an overview | ScienceDirect Topics

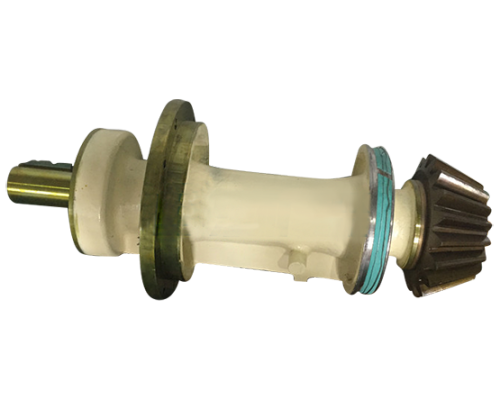

The cone crusher is a modified gyratory crusher. The essential difference is that the shorter spindle of the cone crusher is not suspended, as in the gyratory, but is supported in a curved, universal bearing below the gyratory head or cone (Figure 8.2). Power is transmitted from the source to the countershaft to a V-belt or direct drive.

Learn More

HP800 CRUSHER OPTIMIZATION - H-E Parts

competitor supplied crusher liners, across all three cone crushers. ™ lifting device when liner change-outs are required.

Learn More

cone crusher liner change | FEED TUBE FABRICATED

Liner change Dismantling of crusher Technologically unique, the new generation cone crushers offer unprecedented performance. Their safe and easy maintenance ensure maximum reliability. 5 19 - Antispin device 20 - Head 21 - Upper head bushing 22 - Mantle 23 - Hydraulic adjustment motor 24 - Bowl liner 25 - Bowl liner fixation

Learn More

Research on the Wear Behavior of the Fixed Cone Liner of a

In the working process of a cone crusher, the cone crusher constantly impacts the ore with the change of the distance between the moving cone

Learn More

Cone Crushers | McLanahan

When should I replace my Cone Crusher liner? If the liner is wearing evenly throughout the chamber, you should consider changing out the manganese when it has worn down to about 1" (2.5 cm) thick at the bottom. At about 3/4" to 5/8" (1.9 to 1.6 cm) thick, the manganese will crack, causing the backing material to begin to disintegrate.

Learn More