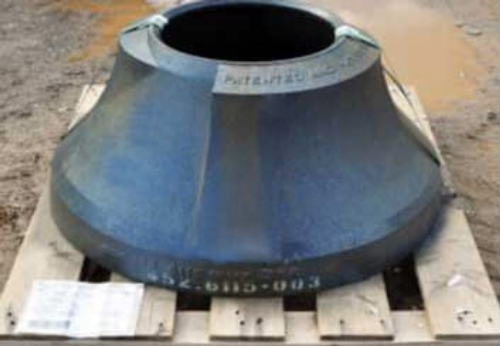

cone cursher liner

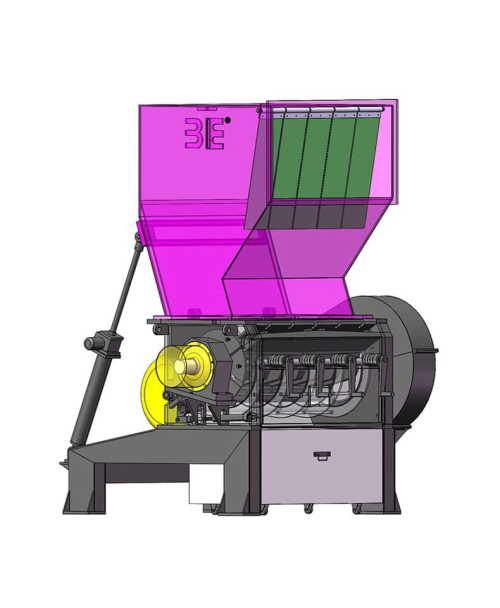

CONE CRUSHER LINER

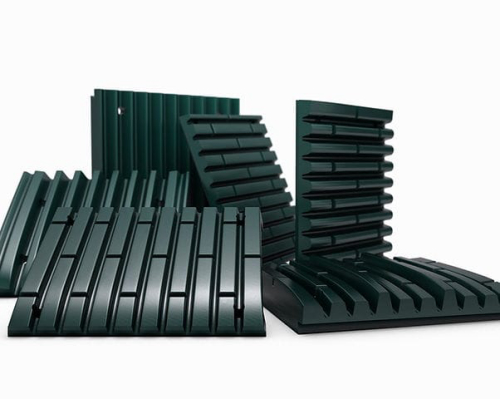

Cone Crusher Liners Key words: Mantle, Bowl Liner, Concave Permanscess has been providing premium manganese steel and hight chrome crusher liners for decades. our liners have been proven in mining and aggregate production to achieve and often exceed the performance of the equivalent castings supplied by Original Equipment Manufactures.

Learn More

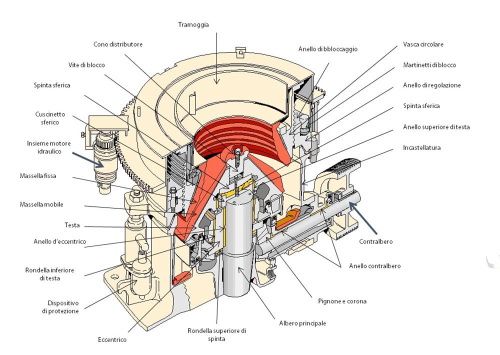

Cone crusher basics in 4 minutes — SRP

This is the starting point for understanding how cone crushers work – and how they can make your mine or quarry more productive. Elsewhere on the site you can find detailed information about all aspects of crushing and screening, but to make sense of these it helps to understand the basics of cone crushing. That’s what you’ll find here!

Learn More

Crusher Liners - H-E Parts

H-E Parts has built a reputation on the reliability and performance of its CME™ range of manganese crusher liners, which are designed to be fully compatible

Learn More

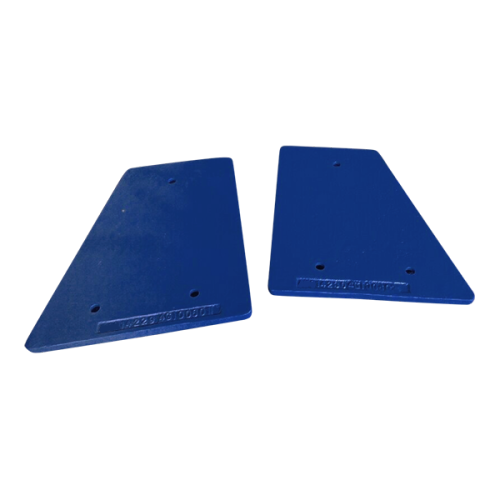

Cone Crusher Replacement Wear Parts – Columbia Steel Casting

OEM liners are based on average conditions, and few cone crushers work under “average” conditions, which is why we have so many options available. Matching sets for better production Our engineers work to improve production throughout the liner life, and to arrive at even wear ratios between mantle and liner to minimize discard weight.

Learn More

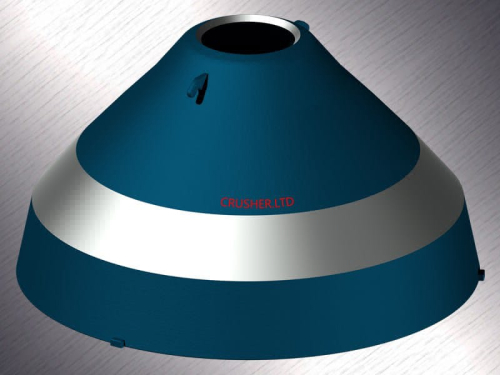

Premium SBM Cone Crusher Liners By Hunan JY Casting

Our TIC inserts cone crusher liners for SBM cone crushers, which can get 1.5- 2 time lifetime than the original liners. Our Customer Support Department is ready to help you with a quote, to check inventory, or to simply answer a technical question. We hope to earn your business by showing you how JY can outperform SBM crusher parts suppliers.

Learn More

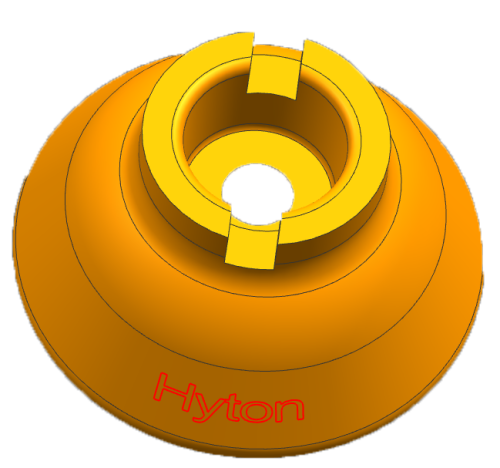

Cone Crusher Mantles & Bowl Liners - Optimum Crush

Optimum Crush has the highest quality cone crusher mantle & bowl liners available! Optimize your mining with our custom engineered products.

Learn More

Fisher Industries hiring Crusher Operator in Livingston, Montana

Fisher Industries is a family of businesses that encompass all aspects of the aggregate production and heavy civil construction industries. Our unique, vertically-integrated business model allows

Learn More

Cone crusher parts - Wear Parts For Industry | Qiming Casting

Cone crusher liners material selection There are 4 types of cone crusher liners materials: Manganese steel. Manganese steel, also called Hadfield steel or Mangalloy, is a steel alloy containing 12-14% manganese. Renowned for its high impact strength and

Learn More

Crusher Liners | World-Leading Crusher Liners | CMS Cepcor

The crusher liners by CMS Cepcor® often exceed the performance of the original manufacturer parts. Contact us today to find out about our range of liners. +1-877-CEPCOR1 (+1-877-2372671)

Learn More

Analysis of the Wear Failure of Cone Crusher Liner at Copper

1/17 · From the first picture “Wear Morphology After Cone Crusher Liners Failure x100”, The cone-crushing motorized lining plate performs an eccentric rotation motion. When it is deflected to the fixed lining plate, it will give a huge impact load to the broken ore, causing the lining plate to be squeezed and plastically deformed.

Learn More

World-Leading Crusher Liners - CMS Cepcor

CMS Cepcor® stock a wide range of cavity liner options for cone crushers along with many jaw plate tooth profile options for jaw crushers and various

Learn More

Crusher Liners | Cone Crusher Liners | Crushing Wear Parts

Crusher Liners CSP is a leading supplier of cast, forged, and fabricated wear solutions to OEM and aftermarket crusher operators. We have over 30 years' experience supplying crushing wear parts to global mining and mineral processing, oil sands, steel, cement, power and aggregate customers.

Learn More

Cone Crusher Cavity Types And - Qiming Machinery

The most important factor in Cone Crusher liner selection is the feed. Cone Crusher Cavity Types. You should have a well-graded feed going into the crushing chamber. A well-graded feed is generally considered as: 90-100% passing the closed-side feed opening. Some people look at 80% of the open side as well and select the smaller of the two.

Learn More

Common Faults and Solutions of Cone Crusher

There are hard-to-crush materials in the crushing cavity of the cone crusher. Too much material in the crushing cavity causes blockage. The liner is broken or worn. Poor lubrication causes the spindle to be wrapped tightly by the bushing. Solution Tighten the bolts and pour and fix them. It is strictly prohibited to enter the non-broken materials.

Learn More

Cone Crusher Liners - Hunan JY Casting

Cone Crushers have been the standard technology in cone crushing for over 70 years and Hunan JY Casting has been making cone crusher liners for this large population of crushers for nearly as long, providing better customer support than typical parts suppliers.

Learn More

Cone Crusher Liners Selection - Wear Parts For Industry | Qiming

2.Crusher Liner’s Material. Cone crusher wear parts, concave and mantle, are casting by manganese steel. Mangalloy, also called manganese steel or Hadfield steel, is a steel alloy

Learn More

Pool Liners Cost Calculator | Livingston, Montana | Manta

In Ground Pool Liners Above Ground Pool Liners Pool Liner Repair Pool Liner Installation Other OR CALL US DIRECTLY 1-888-668-8262 'Pool liner installation near me' is a common search term used by homeowners with small to large swimming pools.

Learn More

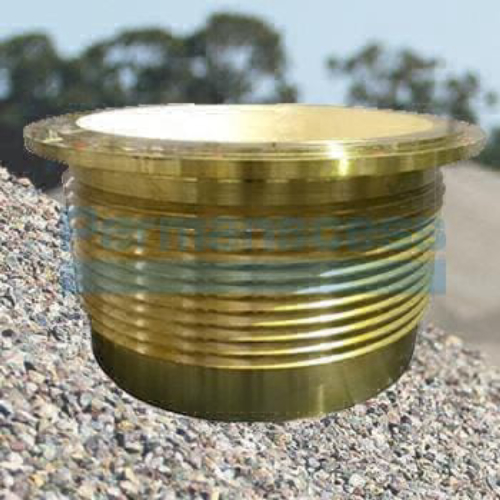

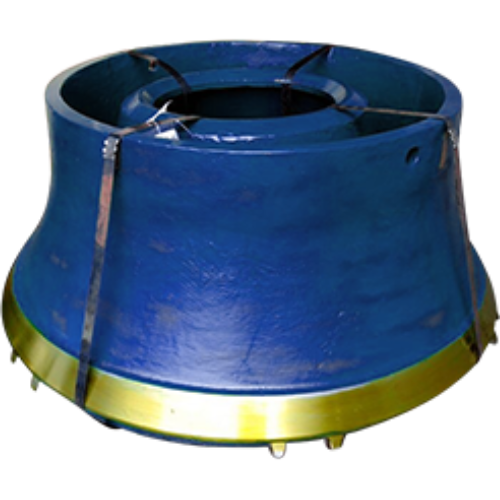

Manganese Mantle Bowl Liner Suit Cone Crusher Wear Parts T900

Manganese Mantle Bowl Liner Suit Cone Crusher Wear Parts T900. Hyton produce High manganese casting liners mainly include Mantle, Bowl Liner, Feed Cone , jaw plate, check plate, Arm Liner , Steel Ball ,and etc.. Cone Crusher Spare Parts-Cone Concave Advantage and Features. 1. Use: Wear parts for crushers in the quarry, mining, cement, aggregate, recycling, shredding and demolition

Learn More

Cone Crusher Liners | Manufacturing and service of

We understand that to keep your equipment and process running smoothly, it may require an approach that is more in-depth than just choosing a different material grade or Cone Crusher

Learn More

Cone Crusher Liners: How to Select and When to Change

6/23 · 90-100% passing the closed-side feed opening. Some people look at 80% of the open side as well and select the smaller of the two. 40-60% passing the midpoint. 0-10% passing the

Learn More

bowl liner for cone crusher | crusher eccentric wearing plate australia

Cone crusher parts : Bowl Liner and Mantle Crusher wear. Cone Crushers for Mining: Cone Crusher Bowl Liners and Mantles for Extreme Conditions Because of the extreme crushing conditions experienced by the crushers used in mining operations, special attention must be paid to the materials used in producing these castings. h6800 series cone

Learn More