primary crusher and secondary crusher

Secondary Crushing Equipment - 911 Metallurgist

The simplest form of secondary crushing stage involves a single crusher, taking its feed by gravity flow direct from the primary with no

Learn More

Primary Crushing - Mineral Processing & Metallurgy

A crusher of these dimensions will break 40 tons per hour to 2½-in. size with a power consumption of 30 h.p. On the other hand, a 14-in. gyratory crusher, working as it should at full capacity, will crush 100 tons per hour to the same size with a power consumption of 70 h.p. ; at 40 tons per hour, it would still require about 50 h.p.

Learn More

Different Types Of Crushers Machine Of Primary,secondary And

Secondary Crusher, Tertiary Crusher, Quaternary Crusher For Fine crushing circuits are more challenging than primary crusher. Secondary Crusher, Tertiary different installation

Learn More

Primary And Secondary Crusher - m.grinderprocess.com

To achieve this top size, the crusher setting is in the range of 200 mm or below, depending on the rock characteristics. The most common type of secondary crusher is the cone crusher. Cone crusher has a much shorter spindle with a larger diameter crushing surface relative to its the vertical dimension.

Learn More

Crusher Selection And Types of Crusher - Engineering Intro

Now a secondary crusher comes into action and further reduces the size. In secondary crusher some sizes of stones may pass directly from sieve

Learn More

Stone Crushing Plant, Primary Secondary - Crusher Mills

In general, a rock crushing plant will have a primary crusher, primary screen, secondary crusher (s) and secondary screen (s), and associated conveyors and stockpiles. primary and secondary stone crusher plant - CGM crusher quarry CGM management concept: reasonable considerate accurate and effective.

Learn More

comparison between primary and secondary crusher

comparison between primary and secondary crusher comparison between primary and secondary crusher. difference between jaw crusher and secondary crusher Goodquarry Article NERC Ope

Learn More

Everything You Need to Know About Rock Crushers

Stages of Rock Crushing: Crushing Stations · 1. Primary Crushing · 2. Secondary Crushing · 3. Tertiary/Quaternary/Final Reduction Crushing.

Learn More

Secondary And Primary Crushers-HN Mining Machinery Manufacturer

The primary coal crushers may be of different types such as: (1) coal jaw, (2) coal hammer, and (3) ring granulator. Secondary coal crusher: Used when the coal coming from the supplier is large enough to be handled by a single crusher. primary crushing equipments for copper. The secondary crusher is mainly used to reclaim the primary crusher

Learn More

Crushers and Their Types - IspatGuru

The output of the primary crusher is fed to a secondary crusher, which further reduces the size of the material. Similarly the output of

Learn More

choosing a primary sui le crusher spain

The Jaw Crusher is suitable for primary and secondary crushing all kinds of minerals and rocks with compressive strength less than 320 MPa Four reasons of choosing primary jaw crusher in crushing plant on 118 th Canton Fair China 10 15 Jaw Crusher . crusher PRIMARY M86A DRAGON.

Learn More

Primary And Secondary Crushers

PRIMARY/SECONDARY CRUSHERS Specifications Model Backhoe/ Weight Max Jaw Jaw Cycle Oil Operating Max Excavator Opening Width Time Flow Pressure Crushing Jaw Crushers - TRIO Engineered Products. TRIO offers a wide range of sizes of primary and secondary jaw crushers. They incorporate steeply aligned toggle seats for

Learn More

Primary and secondary crushers - Welding Alloys

Where the material is not reduced sufficiently in the primary crusher, it is then crushed by a secondary crusher to achieve the correct size of the material. We parts of the crushers

Learn More

Impact Crusher & Cement Crusher Manufacturer - Stedman Machine

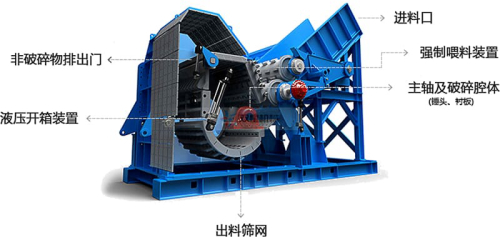

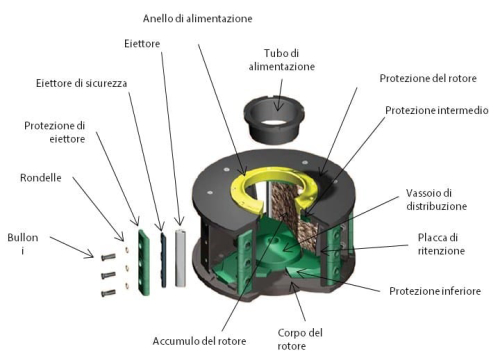

What is an Impact Crusher? An impact crusher is a machine that uses striking as opposed to pressure to reduce the size of a material. Impact crushers are designated as a primary, secondary, tertiary or quarternary rotor crusher depending on which processing stage the equipment is being utilized. Types of Impact Crushers:

Learn More

primary and secondary crushing crusher | Mining & Quarry Plant

7/18 · Complette primary and secondary crushing plant rebuild in 2005 PRIMARY CRUSHER jaw crusher type: ALTERAC C1311, 1300 x 1100 mm (ALTERAC is today Gulin) feeder Mobile Primary and secondary Crusher , Portable Crushing Mobile Crusher

Learn More

how to install a secondary crusher

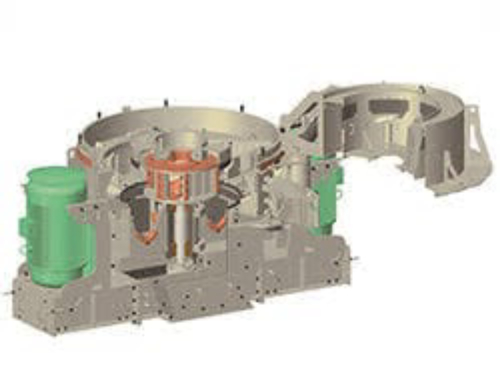

Gyratory crushers. Gyratory crushers are frequently used in the primary crushing stage and a little less often in in the secondary stage. Gyratory crushers have an oscillating shaft. The material is reduced in a crushing cavity, between an external fixed element (bowl liner) and an internal moving element (mantle) mounted on the oscillating

Learn More

Primary And Secondary Crusher

Above 1,000 tph, primary crushers begin to look interesting, and after the throughput reaches 2,000 tph, jaw crushers are very rare, with the exception of a parallel plant layout. Capacity is also determined by the feed size and material type introduced to

Learn More

Definition of secondary crusher

Crushing and pulverizing machines next in line after the primary crushing to further reduce the particle size of shale or other rock.

Learn More

Jaw Crusher | Primary Crusher in Mining & Aggregate - JXSC Mine

Product Introduction. JXSC jaw type rock crusher is usually used as a primary crusher and secondary crusher to reduce the size of medium-hard materials to smaller physical size. Jaw rock crushers are capable of working with the mobile crushing station, underground crushing because of its related small volume. Capacity: 1-1120TPH.

Learn More

Different Types Of Crushers Machine Of Primary,secondary And Tertiary

Several types of coal crushers: in primary or secondary crushing process. Cone crusher is used as fine coal crusher machine, and used in secondary or tertiary Crushers and Equipment Technology in Mining Jaw and Gyratory crushers are two most important types of primary crushers but

Learn More

Primary And Secondary Crushing | Crusher Mills, Cone

Primary and Secondary Crusher Hammers – Wear Parts + Steel Our H79 alloy steel hammers provide reliable, consistent service for secondary and primary crushers. H79 is a

Learn More