crusher wears

Crusher Wear Parts - Weir ESCO

Engineered to outperform -- ESCO® is a leading developer of heavy-duty crusher wear parts for all major makes and models of cone, jaw and gyratory crushers.

Learn More

Wear and Spare Parts for Crushers - Element

Element Group is a leading manufacturer and supplier of spare and wear parts for all types of imported and domestic crushers and screens: jaw, cone,

Learn More

Crusher Wear Parts Supplier | Quarrying & Aggregates

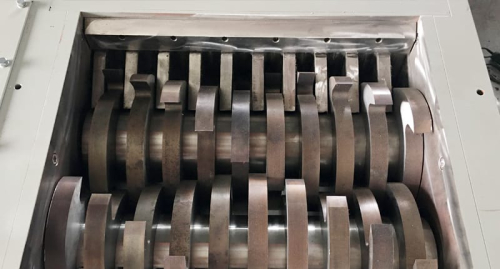

Crusher Wear Parts Supplier. The crusher wear parts are the parts of the crusher that are in direct contact with the material. Large pieces of material are crushed into small pieces by the

Learn More

What Are Crusher Wear Parts? - Groovy Ghoulies

A crusher wear part is a metal part that is designed to withstand excessive wear and tear from crushing and grinding, such as those found in a jaw crusher or cone crusher. Many parts are made of steel because of their strength and durability. However, different types of metals can be used depending on the application.

Learn More

Crusher Wear Parts

Crusher Spares for wear resistant castings for mining, quarry, agricultural, earthmoving, and general heavy engineering machinery spare parts.

Learn More

Outotec introduces renewed crusher wear offering

27/04/2022 · The renewed crusher wears and services offering, from seasonal crushing to high-volume, and high-value operations has been developed in response to customers’ demand for continuous improvements in crushing process performance. Through the renewed offering, aggregates and mining customers can together with Outotec experts easily compare

Learn More

Crusher Wear Parts | OPM-USA | Longest Span Life

Crusher Wear Parts Expert. OPM Heavy Equipment is the expert equipment manufacturer of crusher wear parts for , , , Superior, Barmac, , , , , SBM and many other crusher brands. OPM Heavy Equipment crusher wear parts are the best and surest way to protect your crusher against hazards such as

Learn More

Roll Crusher Wear Parts - Unicast Inc

Wear parts for cone crushers, gyratory crushers, jaw crushers, and roll crushers designed to improve efficiency and reduce costs by extending wear life and

Learn More

Wears For Cone Crushers | Crusher Mills, Cone Crusher, Jaw Crushers

Crusher Wear Parts. including: cone crushers, gyratory crushers, jaw crushers, roll crushers, hammermills, vertical shaft impactors (VSI) Crusher Wear Studies for Better Productivity – from Columbia

Learn More

Expected or Typical "life span" of wear parts of jaw crusher - Crushing

To participate in the 911Metallurgist Forums, be sure to JOIN & LOGIN; Use Add New Topic to ask a New Question/Discussion about Crushing.; OR Select a Topic that Interests you.; Use Add Reply = to Reply/Participate in a Topic/Discussion (most frequent). Using Add Reply allows you to Attach Images or PDF files and provide a more complete input.; Use Add Comment = to

Learn More

Liner wear in jaw crushers - ScienceDirect

01/01/2003 · A cone crusher is a machine commonly used in the mining and aggregates industry. In a cone crusher, the geometry of the crushing chamber is crucial for performance. The objective of this work, where wear was studied in a jaw crusher, is to implement a model to predict the geometry of a worn cone crusher.

Learn More

PDF Crusher Wear Parts Selection Guide Rev 003PDF

08 JAW CRUSHER WEAR PARTS International reserves the right to make changes to the information and design of the machines on this brochure without reservation and notification to the users. Information at time of print considered accurate — International assumes no liability resulting from errors or omissions in this document.

Learn More

Cone Crusher and Gyratory Crusher Replacement wear parts

Cone and Gyratory wear parts. Longer wear life for your crusher's parts. □. Reduced downtime. □. Lower operating costs. □. Improved performance.

Learn More

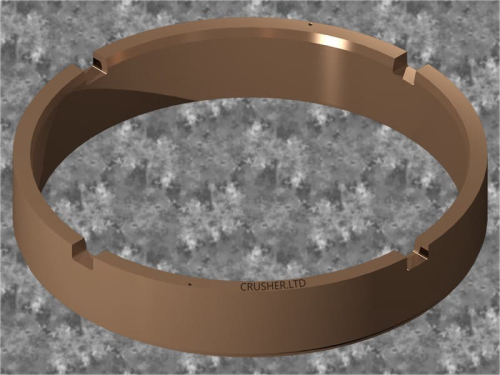

Manganese, Alloy steel and TIC inserts Cone Crusher Wear Parts

Among them, mantles and concaves are also called cone crusher wear parts. Cone crusher mantle, which covers the cone head of the crusher to protect it from wear. It is the inner sacrificial wear liner that sits on the cone head. Cone crusher concave, which sits in the upper frame of the crusher to protect it from wear.

Learn More

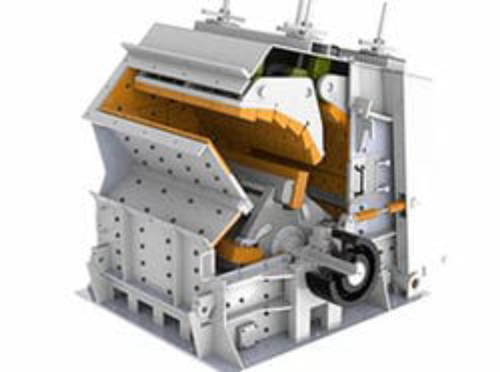

Impact Crusher Wear Parts For Popular Brands By MGS Casting

If you demand the peace of mind that comes with ISO 9001-certified, fully-guaranteed, and warranted replacement parts for your impact crusher, MGS Casting is your best choice! Common Name: blow bars, high manganese blow bars, high chrome blow bars, ceramics blow bars. Cast Material: Cr13,Cr23,Cr26, TIC Insert alloy steel, Ceramic. Cast

Learn More

Crusher Wear Parts - Amsted Global Solutions

A jaw crusher reduces large-sized rocks and other materials by placing them into a compression. A fixed jaw, typically mounted in a V-alignment, is the stationary surface, while the movable jaw

Learn More

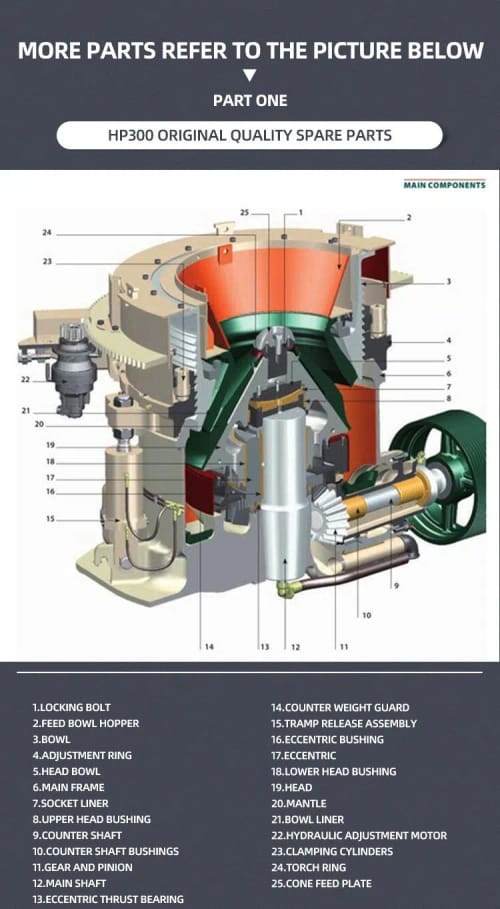

Crushers wear parts

Our crusher wears are available for stationary crushers, including primary gyratory crushers, ® C Series jaw crushers, HP and GP Series cone crushers,

Learn More

Jaw Crusher Liners | Foreman Equipment

OEM Crusher wear parts designed to match original design specifications ensuring the best performance from jaw, cone, and impact crushers Office - Toll Free: 888-852-9021 | 44109 Yale Road West, Chilliwack, B.C. V2R 3Z9

Learn More

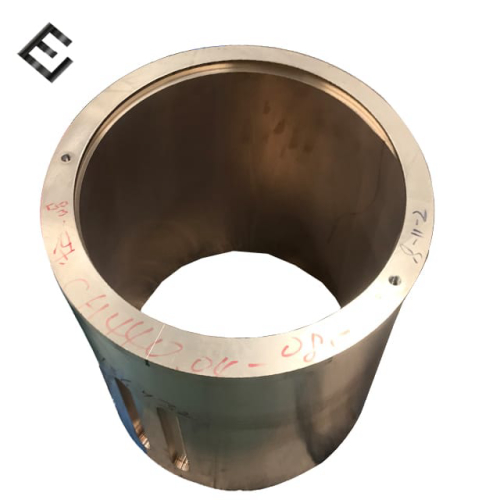

Cone Crusher Wear Parts - Amcast

Cone Crusher Wear Parts. Superior performance comes from AMCAST's patented MNXTM Manganese Alloy or GPTM/ GPFTM Manganese Steel with Reinforced Inlays.

Learn More

Outotec expands O-Series crusher wear parts range

23/06/2022 · Outotec O-Series crusher wears are available for Outotec’s stationary and mobile crushers in mining and aggregates industries. The protective wears will include selection of wears for HP Series and GP Series cone crushers and C-Series jaw crushers. The O-Series wear parts are being featured at the Hillhead Quarry event

Learn More

JAW CRUSHER WEAR PARTS - Precision Casting

Our crusher jaws are cast from 18% manganese 3% chrome iron. We are also able to custom design jaws that offer increased performance by using ultra heavy duty 21% manganese and 2% chrome iron, and 24% manganese and 3% chrome iron. Special heat treatment methods are used to make each jaw crusher liner have a higher degree of wear resistance and

Learn More