why do you need to know the specific cutting force for a workpiece material?

Determination of specific cutting force components and exponents when

The increase in force has an impact on the workload and tool life of the Workpiece-Fixture-Machine Tool-Cutting Tool (WFMC) system. Therefore, in applying the Kienzle and Viktor relationship to calculation of the cutting force, we need to know the change in the specific cutting force (kc1.1) and the exponent related to it (z) in cases where a

Learn More

Machinability and The Specific Cutting Force for Work-piece

Machinability and The Specific Cutting Force for Work-piece Materials The condition and physical properties of the work material have a direct influence on the machinability of a work material. The various conditions and characteristics described as "condition of work material," individually and in combinations.

Learn More

exsample of crusher spare parts | why do you need to know the specific

Easy to transport mobile concrete plants have axles and tires in its main chassis. Thanks to pre-assembled structure, they can be installed in a very short period of time (1-2 days) View Details

Learn More

The Effect of Coatings on Cutting Force in Turning of C45 Steel

coatings should cause a change in the force during turning of a particular workpiece, and this is verified in this paper in comparison with

Learn More

How Plasma Cutting Works and What Is Plasma Cutting - WeldingPros

It allows you to effectively process a high-quality blank for thick and medium sheet metals. Plasma arc cutting is ideal for the automation of the cutting process. When plasma arc cutting underwater - it creates a very low level of noise and produces a very low heat exposure too. Image of Plasma Cutting torch.

Learn More

HP300 ADJSTM RING KIT | why do you need to know the specific cutting

Our equipment covers the entire unit operation range for aggregate plants. Westpro possesses the industry expertise to combine these products in a modular plant, providing its customers a complete process solution.

Learn More

Modeling Cutting Forces in High-Speed Turning ... - Redalyc

Keywords: Cutting forces, Specific energy consumption, High-speed turning, Future studies should further investigate machine energy consumption in

Learn More

Cutting Speed Chart for Different Materials in Turning, Drilling and

Cutting speed, also known as surface speed, refers to the speed at the outside edge of the tool as it is cutting. It is measured in surface feet per minute (SFM). Cutting speed is mainly depending on the type of materials and cutting tools, related to their hardness. The harder the material, the slower the cutting speed should be.

Learn More

Fundamentals of Machining - IIE

workpiece surface finish and integrity, tool life, force and power 21.17 Why do you think the maximum temperature in orthogonal cutting is located at.

Learn More

Why is it important to know the hardness of the workpiece material?

What are important properties of a workpiece material that can improve machinability? A work material having a low hardness and low work-hardening rate produces small cutting forces and low contact pressure at the tool-chip interface, consequently causing a low temperature rising at the cutting region, hence, shows a good machinability.Low hardness values make a material easier to machine.

Learn More

Cutting Formulas | Machining Formula Collection - KEYENCE

lm (mm): Length of workpiece. l (mm/min): Machined length per minute. memo. This formula is used to calculate the machining time from the length of the workpiece and the spindle speed. Example: Feed (f) = 0.2 mm/rev. Spindle speed (n) = 1100 min -1. Length of workpiece (lm) = 120 mm. First, the machined length per minute is calculated, in this

Learn More

Application of a Force Model Adapted for the Precise Turning

coatings) and workpiece materials require the exact knowledge of the cutting The main values of specific cutting forces were introduced for precision.

Learn More

HP5 CNTRWGHT LINER SET | why do you need to know the specific cutting

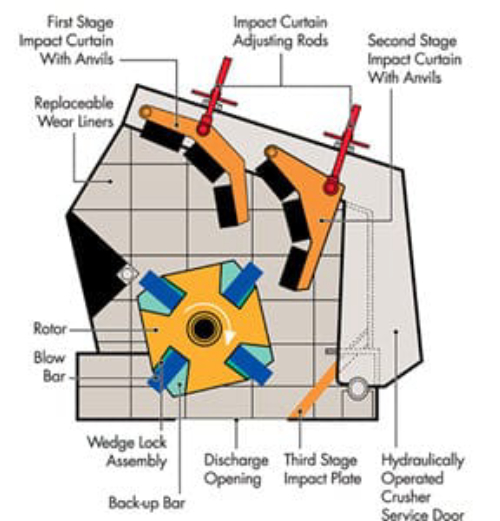

PDF Crushing and Screening Handbook. Preface Table of Contents 's Mining and Construction Technology Quarry Process + Process Integration and Optimization (PIO) Feeders Crushing Equipment C-Series Jaw Crushers Superior MK-II Primary Gyratory Crushers GP Series Cone Crushers MP Series Cone Crushers HP Series Cone

Learn More

Key to model-based machining: specific cutting force | Sirris

In addition to the material, the specific cutting force is also influenced by the chip angle. For example, there is a rule of thumb that for every degree that the cutting edge becomes more positive, 1.5 percent less force is required to form a chip. This rule of thumb is instinctively supported, as a sharp knife cuts easier.

Learn More

Cutting Forces in Turning Operations - UPCommons

In machining, the material of the workpiece used should be taken into account in order to predict the forces and reactions that the cutting operation will

Learn More

SEALPLATE, SWING JAW 1312 | why do you need to know

Optitooth jaw plate. On January 1 Mining and Rock Solutions Division Crushing and Screening became a business area of its own within Group. We are called Rock Processing Solutions and you’ll find all our products within Stationary Crushing and Screening, Mobile Crushing and Screening and Attachment Tools (Breakers) on

Learn More

A Method to Determine Cutting Force Coefficients in Turning

I. INTRODUCTION prediction of cutting forces is essential for workpiece obtained from experiments for a specific tool-workpiece pair.

Learn More

Measuring the cutting force | Cutting Tool Engineering

Aug 01, · The cutting force between the tool and the workpiece causes small motions of the top plate relative to the bottom plate (proportional to the stiffness of the load cells). That

Learn More

PDF) Determination of specific cutting force components and

Choosing more intensive cutting data usually associated with an increase in cutting forces. The increase in force has an impact on the workload

Learn More

C160 FLYWHEEL C160 16XSPC who owns bond it

Name Provider Purpose Expiry Type; _ga: Google: Registers a unique ID that is used to generate statistical data on how the visitor uses the website. 2 years

Learn More

Kennametal® End Milling Force, Torque, and Power Calculator

Conversion of Workpiece Material Rockwell (Optional) Skip this step if you already know the Brinell hardness number(HB) Hardness HRB OR HRC into Brinell Hardness (HB) F t Tangential cutting force lb N. T Torque at the cutter. in.-lb Nm. Machining Power. P s at the

Learn More