can crusher plans pdf

PDF | Pneumatics | Piston - Scribd

A is the perfect device for. fWorking Principle. The works on a simple slider-. crank mechanism. The crank is a small circular disk which is. rotated by means of a handle or a motor. The connecting rod is a lever or link which. connects the crank and piston. The piston is a plunger which slides inside the.

Learn More

Wooden : 4 Steps (with Pictures) - Instructables

Here are the pieces you will need to cut out. I used a router circle jig to cut the crusher head. It does not have to be perfect, nor round. For the can holder,

Learn More

Mechanism Report - Abstract In this ... - StuDocu

This gives help in recycling the small stacks. come-s in many designs pneumatic, hydraulic, wood and aluminum. The name of the man who invented the

Learn More

The Soda Challenge - jstor

four to design soda can crushers (for looking for in a soda at the beginning of the program. designs as well the crush-.

Learn More

Category: - OHO - search engine for sustainable open

Contains PDF Blueprints: No Contains CAD Files: No License: unknown. File:CWL.245694.1.jpg. Aluminum Plans - Gizmoplans. Add to cartDescriptionDownload Plans For , Plans show How to Make a Electric , download plans and start building today.? Easily build, sel Contains PDF Blueprints: No Contains CAD Files: No

Learn More

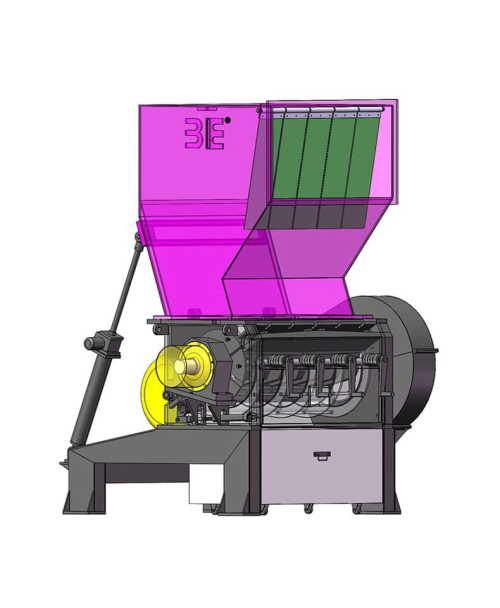

Design and Fabrication of Aluminium Tin

operated aluminium tin can crusher. A can be defined as “A device used for crushing aluminium cans for achieving 65% volume reduction and

Learn More

PDF PNEUMATIC - IRJET-International Research Journal of ...PDF

4. Crushed aluminum can must immediately fall into the aluminum can bin without human intervention. 5. The aluminum can bin must slide in and out of the crusher. The aluminum can bin must be sized to hold 20 crushed cans. 7. All parts of the must be fabricated. 8. The design is to be one unit. 9. Must be manually operated.

Learn More

Automated Project

portions of the crusher was what made us scrap the project along with no involvement of the robot claw. The second sketch (Sketch B) developed set the precedent for the final product as

Learn More

Model - DIY Builds

PRINCESS AUTO — SHOP SALE FLYER SHOWCASE Search Select My Store: Gift Cards Log In EN English MY CART (0) Clearance $61.99 - $89.99 $66.99 Home / Driveline / Hydraulics / Cylinders / Pneumatic Cylinders / 63 Mm Bore Pneumatic Tie Rod Cylinders

Learn More

20 Ways To Build A DIY From Home

You'll need wood, a hinge, screws, a drill, and a handsaw. This is a simple woodworking project, easy for anyone to do.

Learn More

Can-Do - Woodworker's Journal

81 Here’s a woodworking project that’s sure to get put through it’s paces. If you’ve ever witnessed a store-bought fall apart within just a year or two of use,

Learn More

PDF Design Project Brief Mfg./Environmental Sector ProjectPDF

This mechanism can be powered and controlled by either pneumatics, electrical, or a combination • is triggered by the retract stroke of the . • use a robot that: • performs the loading of fresh cans into the . • interfaces with the electric relay control system (operates the ) to signal the start and stop of the

Learn More

PDF Automated Project - tlee753.comPDF

device must be able to fit over the conveyer belt • device must be able to allow robot claw to release can into crushing chamber • the must be able to crusher the entire can without fail • pneumatic actuator must be wired into the program controlled logic interface • robot must be programmed so as to

Learn More

PDF Can-Do - TFD215PDF

81 Here's a woodworking project that's sure to get put through it's paces. If you've ever witnessed a store-bought fall apart within just a year or two of use, here's a way to make your own and have it go the distance. Basically, many fabricated models aren't rugged enough. They're made of light-

Learn More

PNEUMATIC - IRJET-International Research

4. Crushed aluminum can must immediately fall into the aluminum can bin without human intervention. 5. The aluminum can bin must slide in and out of the crusher. The aluminum can bin must be sized to hold 20 crushed cans. 7. All parts of the must be fabricated. 8. The design is to be one unit. 9. Must be manually operated.

Learn More

The Dual Stroke - IJRDET

In designing and fabricating this tin , a flow of methods had to be used for the design to crush the tin. First of all, a process planning had to be

Learn More

Can-Do - Moodle

project and become a better woodworker. To download these plans, you will need Adobe Reader installed on your computer. If you want to get.

Learn More

Free Woodworking Plan.com

Free plans to build your own Can Crusher. Beverage cans taking up too much room? Not anymore once you build a wooden like this one.

Learn More

PDF) Design of a Beverage : A Lean Thinking Solution for

The study focused on the design of an aluminium that can be used domestically to crush empty beverage can and return them to the industry in order to encourage sustainability in the

Learn More

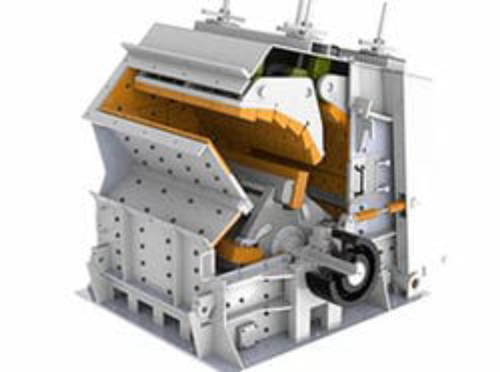

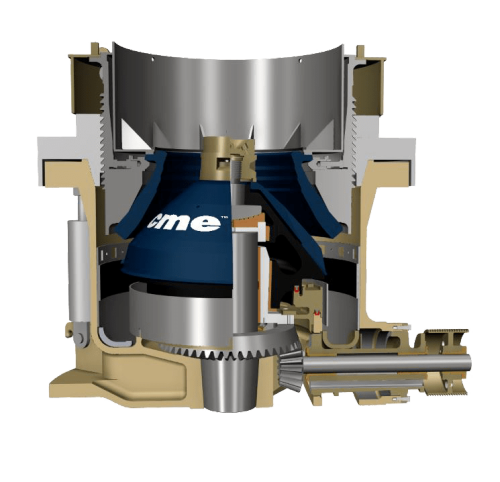

Crushing Plant Design and Layout Considerations

design, so that they can identify ways of reducing overall electrical power consumption. • Electronic control of crusher discharge opening and feed rate. With adjustment of a crusher’s discharge opening, as the production continues through an on-line coarse size analysis of the crushed product (digital image analyses). Dance, A. 2001)

Learn More