cone crusher

Cone Crusher - 911 Metallurgist

Cone crushers are used in AG and SAG grinding circuits to increase tonnage by effectively dealing with any pebble (critical size) build-up

Learn More

Cone Crusher | Hazemag North America

The CYBAS- i Cone crusher is a modern high performance hydraulically adjusted (hydroset-type) cone crusher, an enhancement of the original legendary CYBAS Cone. It is the result of

Learn More

Cone Crushers | Rock Crushers | Aggregate Crusher - Lippmann-Milwaukee

Cone Crushers feature a unique combination of crusher speed, throw, and cavity design. This combination has proved revolutionary in providing higher capacity and superior product quality, and in providing a wider range of application suitability. From limestone to aconite, from ballast production to manufactured sand, and from small portable

Learn More

Cone Crusher For Sale - Secondary Crushing Equipment

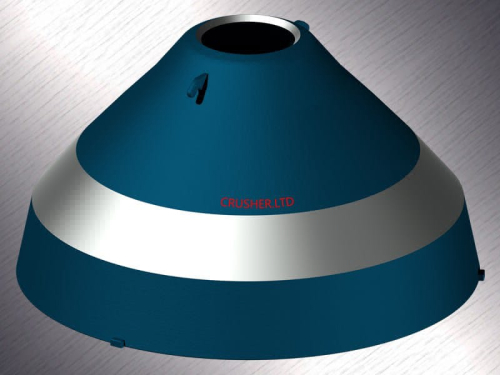

Cone crusher plant only needs to replace the fixed cone lining plate, moving cone lining plate, crushing cavity type from super coarse cavity type to short head ultra-fine cavity-type arbitrary transformation, to adapt to a large range of product particle size requirements. 6. Reasonable structure, reliable operation, low operation cost

Learn More

Cone Crushers — SRP

cone crushers are an excellent choice in secondary, tertiary, quaternary and pebble-crushing applications. They are equipped with the hydraulic Hydroset™ system, which provides safety and setting-adjustment functions. Our crusher automation system delivers real-time performance management, enabling you to monitor and optimize crusher performance and productivity.

Learn More

spareparts of gp11f cone crusher hs code (2022

Stone Cone Crusher Wear Plate Suit for T300 Spare. Stone Cone Crusher Wear Plate Suit for T300 Spare Parts, Find Details about Stone Cone Crusher, Crusher Wear Plate from Stone Cone Crusher Wear Plate Suit for T300 Spare Parts - Maanshan City Hyton Heavy Industry Technology Development Co., Ltd. HS Code: 84749000.

Learn More

HP Series™ cone crushers - Outotec

Crusher automation. Outotec IC70C™ is a crusher automation system that further improves the operation of your ® HP™ crusher. Using it can increase your production by more than 10%. With Outotec IC70C™ you can control maintenance, setting modifications, production follow-up and data extraction.

Learn More

What is a Cone Crusher? (with picture) - About Mechanics

A cone crusher is an essential part of the process of breaking rocks into smaller pieces. This conical-shaped machine's unique design

Learn More

Used Cone Crusher For Sale | Cone Crushers | Omnia Machinery

Cone crushers are a compression machine that reduces materials by compressing/squeezing the material between moving and stationary elements. Our used cone crushers are able to be used as primary or secondary crushers and are employed in order to compress the feed material between two pieces of steel, this process reduces the size considerably.

Learn More

Marcy ® Lab Cone Crusher - Gilson Company

Marcy® Cone Crushers reduce medium to hard materials, such as aggregate and mineral ores. These crushers are powerful and tough enough for the continuous

Learn More

Trio® cone crushers - The Weir Group

Trio® cone crushers offer robust reduction for medium or above hardness feed material and are suitable for secondary, tertiary or if the

Learn More

Patriot® Cone Crusher - Superior Industries

Typically applied in secondary and tertiary stages, the cone crusher produces reduction ratios of 6:1 to 4:1. Bushing cones, like Superior's Patriot Cone

Learn More

A Detailed Overview of Cone Crushers and What You

Jaw crushers are a compression crusher that uses a set of jaws to crush aggregate materials. This machine features a fixed jaw and a moving jaw,

Learn More

kubria® Cone Crusher - thyssenkrupp Mining Technologies

Cone crushers work on the principle of compression. The crusher squeezes the material until it breaks apart. By opening the crushing gap,

Learn More

Cone Crusher - an overview | ScienceDirect Topics

These crushers are designed so that the head-to-depth ratio is larger than the standard gyratory crusher and the cone angles are much flatter and the slope of the mantle and the concaves

Learn More

Raptor® Cone Crushers for Aggregates

Raptor cone crushers installed at aggregate plant for crushing.

Learn More

Cone Crusher - Eastman Rock Crusher

Cone Crusher can crush the materials with compressive strength not exceeding 350MPa, such as river pebbles, granite, basalt. gp, hp cone crusher. compound cone crusher is a modern high performance crusher designed and developed by EASTMAN according to the needs of users, based on the principle of lamination crushing and the concept of more

Learn More

Cone Crusher | Working Principle | Animation | Engineering Intro

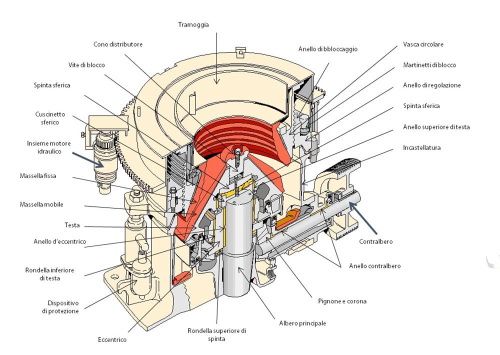

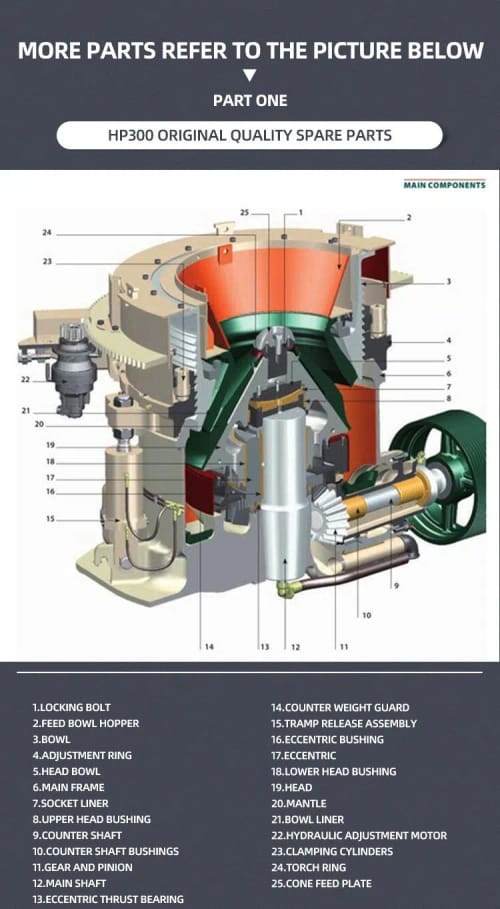

Cone crusher parts It breaks the rocks by squeezing it between the gyrating spindles. These spindles are fully covered with resistant mantle and a manganese bowl liner covers the hopper. Rocks get squeezed at the same moment when it enters in between the bowl liner and mantle. Only one time breaking is carryout of larger pieces of rocks from ore.

Learn More

CONE CRUSHER - CT950 - CONETECH ENGINEERING

CONETECH cone crushers are based on Roller Bearing System which makes them superior compared to cone crushers with bronze hydrostatic bearing. Since CONETECH cone crushers do not have upper bearings, its inlet is completely open, and this enables homogenous feeding into crushing chamber in coarse feeding applications.

Learn More

Cone Crushers | Moore Watson Ltd

The MP Cone Crusher is advanced in design, more compact with a higher crushing ability and efficiency to provide better size reduction. Operators can choose the auto control mode, various chambers and other features by adjusting the closed side settings (CSS). All models are easy to operate and maintain, with high production and efficiency.

Learn More

Efficient use of cone crushers - Mineral Processing

A cone crusher is often used in the second to third crushing stage and operates according to the pressure crushing principle. It is suitable primarily for

Learn More