thread milling

Thread Milling vs. Tapping: Advantages & Disadvantages

In the machining of very shallow blind threads in thin materials, the thread mill allows for maximum threads in a very short distance. The one disadvantage of thread milling is you need to be equipped with a high-speed spindle in order to do it properly, such as the ones found in our line of high-speed milling machines with spindle speeds up 60,000 RPM.

Learn More

Thread Mills | Emuge Corporation

THREAD MILLING TECHNOLOGY ADVANTAGES Produce threads with excellent form, finish, and dimensional accuracy Easy machining of difficult materials Eliminate the possibilities and consequences of tap breakage Achieve full-bottom threading and precise thread depth control Optimum positional accuracy Pitch diameter can be controlled by CNC offset

Learn More

Thread Milling VS. Tapping | Source Products

5/11 · Tapping: Advantages and Disadvantages. The greatest advantage of tapping is speed. High-speed tapping centers set up with a rigid tap can thread holes in a fraction of the

Learn More

Thread Mill CNC Program Generator - GUHRING

In an effort to make using Guhring thread mills even more user-friendly, we have developed the intuitive and complimentary “CNC Gühro Threadmill” software. There are only 5 steps to take: 1. Specify the thread data. UNC, UNF, Metric, Metric Fine, UN, etc. 2. Select the material you are threading. This will optimize the feeds and speeds.

Learn More

Thread Mill Code Generator - Scientific Cutting Tools, Inc

Thread Mill Code Generator. Units of Measure. Input Units: Inches Input Units: Millimeters G-Code Units: Inches G-Code Units: Millimeters Thread Type. UN Thread Thread Direction. Right Hand Left Hand Cut Type. Climb Cut Conventional Cut Major Diameter (A) Minor Diameter (B) Thread Depth (C) Threads per Inch

Learn More

How To Thread Mill with Simple G-Code

12/13 · This works with single and multi point thread mills G-Code Provided Below!This video recap shows how to use simple G-code to create perfectly milled threads.

Learn More

Understanding Threads & Thread Mills - In The Loupe - Harvey

2022/3/14 · Right-hand internal thread milling is where cutters move counterclockwise in an upwards direction to ensure that climb milling is achieved. Left-hand internal thread milling a left-hand thread follows in the opposite direction, from top to bottom, also in a counterclockwise path to ensure that climb milling is achieved. 4.

Learn More

ISCAR Cutting Tools - Threading - Internal Thread Milling - Iscar

Threading - Internal Thread Milling.

Learn More

Threadmill Calculator | Gorilla Mill

Based in Milwaukee, WI – Gorilla Mill has over 30 years experience manufacturing the best carbide drills, end mills and cutting tools in the industry. *The RPM and Chip Load that automatically populates in this calculator are the factory suggested parameters for

Learn More

Thread milling, simplified | Cutting Tool Engineering

9/1 · Harvey Tool offer standard through-coolant thread mills as small as 10-32 and as large as ½-13. Advent’s Hartford gave this example. “Say you need to cut a 6"-12 thread and then a 5"-10 thread. Using an inserted thread mill, all you need to do is change inserts from the 12 pitch to the 10 pitch at $30 per insert.

Learn More

When Thread Milling Makes Sense | Production Machining

Thread milling achieves a better thread quality than tapping because the threads are being properly machined with the clearance needed to

Learn More

What is Thread Milling | CNCLATHING

Thread milling is a metalworking process to cut threads at different sizes through the circular ramping movement of a rotating tool, the thread

Learn More

Thread Mills - Haas Automation

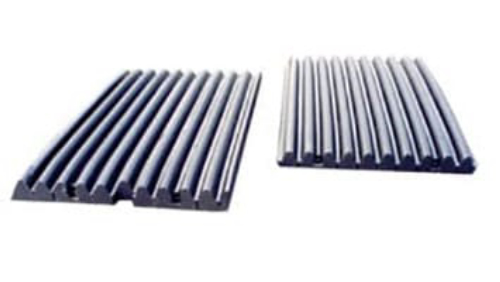

Thread mills differ from taps, because they have a smaller diameter than the thread size produced.The thread mill cutter must be able to enter the drilled hole, and then interpolate the thread profile. Because offset adjustments can be used to compensate for tool wear - as long as the thread form is still good - thread mills typically produce more threaded holes per tool than taps.

Learn More

Thread Milling - MORSE Cutting Tools

Thread Milling MORSE offers high-performance Thread Mills with and without internal coolant. The Thread Mills were designed and produced according to ISO, UN, UNJ, MJ, W, BSPT,

Learn More

Thread Milling Cutters-Single Form-Metric - Harvey Tool

Holemaking & Threading · Single thread form – can mill multiple pitches · Cuts internal and external 60° UN threads · Mills right hand and left hand threads · Tip

Learn More

Solid Carbide Thread Mills - Karnasch Tools

The Karnasch solid carbide thread mills enable the production of threads in steel as well as in abrasive materials. In sizes from M 3 to M 12, with a diamond

Learn More

Solid carbide thread milling cutters - Guhring UK

In order to make the machining with Guhring thread milling cutters even more user friendly, we have developed the intuitive “CNC Gühro. Thread Mill”. “CNC Gühro

Learn More

How to choose thread milling cutters - Coromant

How to choose thread milling cutters Single or multi-row thread milling concepts are suitable for different applications. Single row For internal, medium to large threads For larger, external threads on asymmetric components When stability is bad - such as for milling threads requiring long tool overhangs and/or in thin-walled components

Learn More

Thread milling cutter - EMUGE-FRANKEN

solid carbide thread milling cutters with countersinking step · (R) GSF-Z-2xD-R15-IKZ-HB-TICN. Possible thread depth. Details.

Learn More

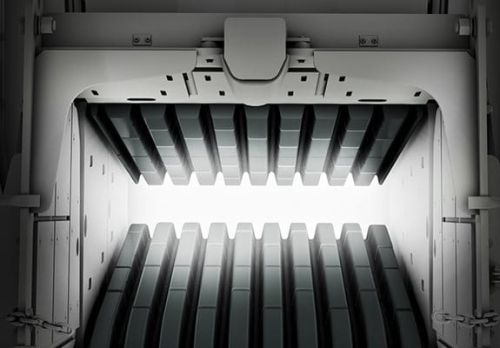

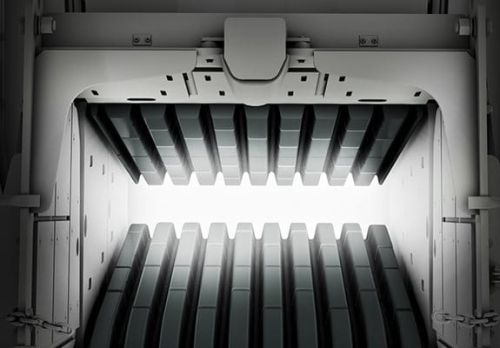

Thread Milling | BME Attachments

Davenport Thread Mill We are now offering a threadmill attachment for your Davenport automatic screw machine. Like our other threadmilling attachments, it can easily be converted to a polygon attachment. Just change the gears! Depicted above, our Davenport Threadmill/Polygon is a revolutionary development as it is the first of its kind to be produced for the Davenport.

Learn More

Thread Mill - DATRON CNC Milling Tools

For machining threads, these thread mills cover both ranges of Metric and Imperial sizes. This design of thread mills require you to mill or drill a hole

Learn More