roll crusher working principle

Roll Crushers - SolidsWiki

The roll crushers are not as productive as cone crushers, with respect to volume, and they do have a little higher maintenance

Learn More

The roller crusher working principle and matters Detailed

Relative rotation of the two roll gap to a certain extent, change the gap, can maximum discharging granularity control products. Double roll crusher is the use

Learn More

Roll Crusher Working Principle

The working principle: The roll crusher will be broken material feeding the mouth fall between two rollers, extrusion, finished product material nature. When the weather is good or not broken, the roll crusher roller but by hydraulic cylinder or the role of the spring automatic, make the roll gap

Learn More

Double Toothed Roll Crusher - Fote Machinery

The material enters the crushing chamber by the impact force of the deep tooth gear for the first crushing. The

Learn More

Roll Crushers - Top 2022 Models - 911 Metallurgist

Modern rolls have both cylinders positively driven by separate motors, so that they rotate inward and downward. Rolls crush by nipping the feed between the

Learn More

Working Principle Of Smooth Roll Crusher Compression - Stone

double roll crusher for sale - beltconveyers.netroll crushers working. roll crushers are compression type (roll crushers employed for minerals &helip; Rotating roller working

Learn More

Single Roll Crusher Working Principle Definition In Reunion

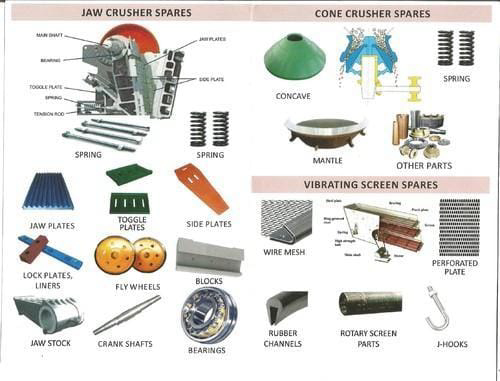

What Is A Jaw Crusher MEKA Crushing Equipment / the working principle of jaw crushers all jaw crushers feature two jaws one of which is fixed while the other moves. the working principle of jaw crushers is based on the reciprocating movement of the movable jaw that compresses and crushes the rock or ore between itself and the fixed jaw, as the material enters the zone between the jaws.

Learn More

Roll crusher working principle | Henan Deya Machinery Co., Ltd

8/20 · The structure of the single roll crusher is shown in Figure 3. The crushing mechanism consists of a rotating roll 1 and a jaw plate 4. The jaws are mounted on a bolt with

Learn More

Roller Crusher | Single/Double Roll Crushers - JSXC Mine

Rock Roll crusher is fine crusher equipment that similar to the hammer crusher. It can crush the compressive strength of less than 160 MPA of materials. Medium feed size, and adjustable discharge size. With the characteristic of low maintenance costs, low requirements for water, reliable performance, less power consumption, less dust, low noise

Learn More

Application of the roller-crusher principle to processing corncobs

Home · Student Research · Theses and Dissertations; Application of the roller-crusher principle to processing corncobs

Learn More

Working Principle Of A Crusher

The motor transmits power through belt, drives the moving jaw to do periodic motion . What is the working principle of jaw crusher? – Yahoo! Answers. Best Answer: The main rack structure of Jaw Crusher are the eccentric shaft, the pulley, flywheel, moving jaw , side rack , elbow plate, Wrist plate back .

Learn More

Roll Mill Ball Mill Working Principle | Crusher Mills, Cone Crusher

rolling mill working principle - Crusher South Africa. Dec 04, · rod mill working principle. Rod Mill Application and Working Principle,Rod Grinding mill Rod mill has dry and wet two sorts to decide on, Users shall

Learn More

Roll Crusher Working Principle Manufacture and Roll Crusher

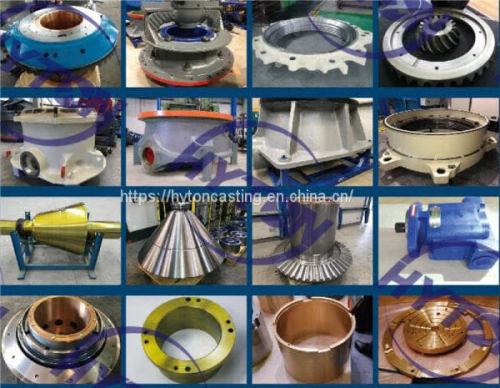

Roll Crusher Working Principle - manufacturer, factory, supplier from China Hot Sale Concrete Impact Crusher With High Efficiency Cone Crushers are Suitable for all Crushing Needs

Learn More

The Working Principle of Roll Crusher

Material is feeding from the feeding mouth above. Through two opposite rotating grinding roller, with the aid of friction and gravity, the

Learn More

How about Working Principle Structure of Roller Crusher

8/10 · 1. the series of roll crusher is mainly composed of the roller, the roller support bearings, compaction and adjusting device and driving unit and other parts. 2, the adjustment of the discharging granularity: with a wedge or gasket between the two roller adjustment device, adjusting bolt, wedge at the top of the device when the adjusting bolt will wedge pulled up,

Learn More

What's a Double-Roller Crusher?

The working principle of the roller crusher is that two sets of separately driven roller shafts crush the material by the squeezing force and

Learn More

Roll Crusher - Mineral Processing

When the two-roller crusher works, the two rollers rotate towards each other, and the material entering the crushing roller is affected by the friction between

Learn More

Working principle of double tooth roller crusher - Exhibition

Each roller has a radially extending crushing tooth. However, large pieces of material cannot enter the occlusal area of the crushing teeth on

Learn More

Roll Crushers | McLanahan

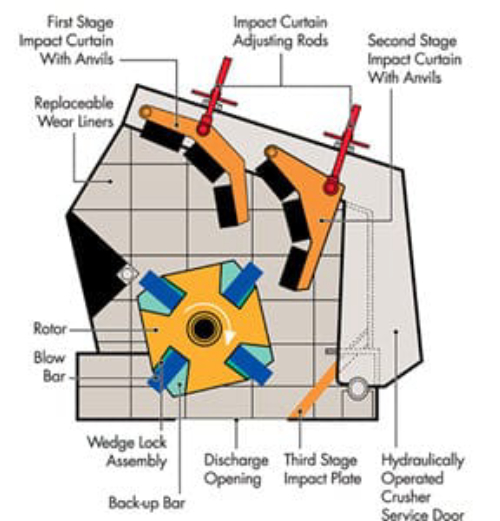

How Roll Crushers Work Whether the application requires a single-stage or two-stage crusher, the forces necessary to perform the crushing remain the same: a combination of impact, shear and compression. The impact force occurs as the material enters the crusher and is impacted by the rotating roll.

Learn More

Roll Mill Roller Mill Working Principle | Crusher Mills, Cone Crusher

Working principle of the LOESCHE 2+2 / 3 or tandem rolling mill, the To embody this rolling principle in the roll working principle of rolling mill - apparatus for Crusher Equipment; Grinding Equipment; Mobile Crusher; Feeding &Conveying; Beneficiation Equipment; Screening &Washing; working principle of rolling mill.

Learn More

Double Roll Crusher - Fote Machinery

Roller Crusher Working Principle. The materials to be crushed fall from the feeding mouth to the space between the two rolls, after being squeezed and

Learn More